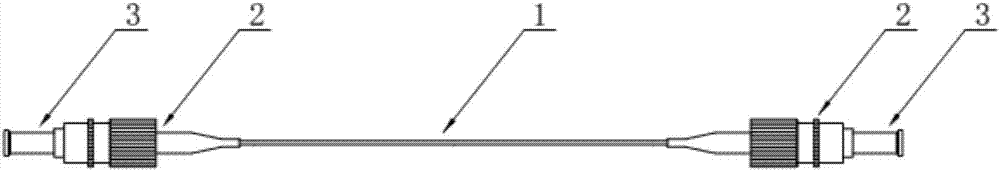

A kind of processing method of fc type chalcogenide glass optical fiber connector

A technology of optical fiber connector and chalcogenide glass, which is applied in the coupling of optical waveguide, light guide, optics, etc., can solve the problems of blank processing, etc., and achieve the effects of convenient coupling connection, wide source, and low insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

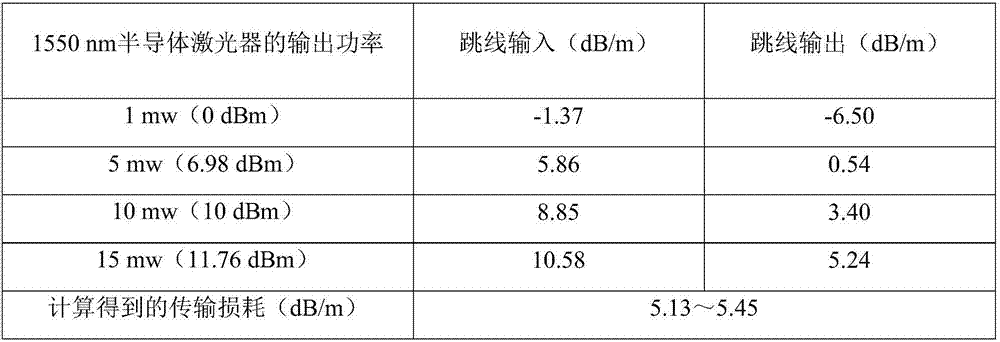

[0029] Embodiment 1: with the Ge that has PES organic plastic coating layer 15 Sb 20 Se 65 Taking chalcogenide glass optical fiber as an example, it is processed into FC type chalcogenide glass optical fiber connector. The processing method includes the following steps:

[0030] 1) Select a section of Ge with a PES organic plastic coating 15 Sb 20 Se 65 For chalcogenide glass optical fiber, prepare two ceramic ferrules with spherical end faces. The inner diameters of the two ceramic ferrules are both 250 μm, and prepare two sets of conventional connection components required for the assembly of optical fiber connectors;

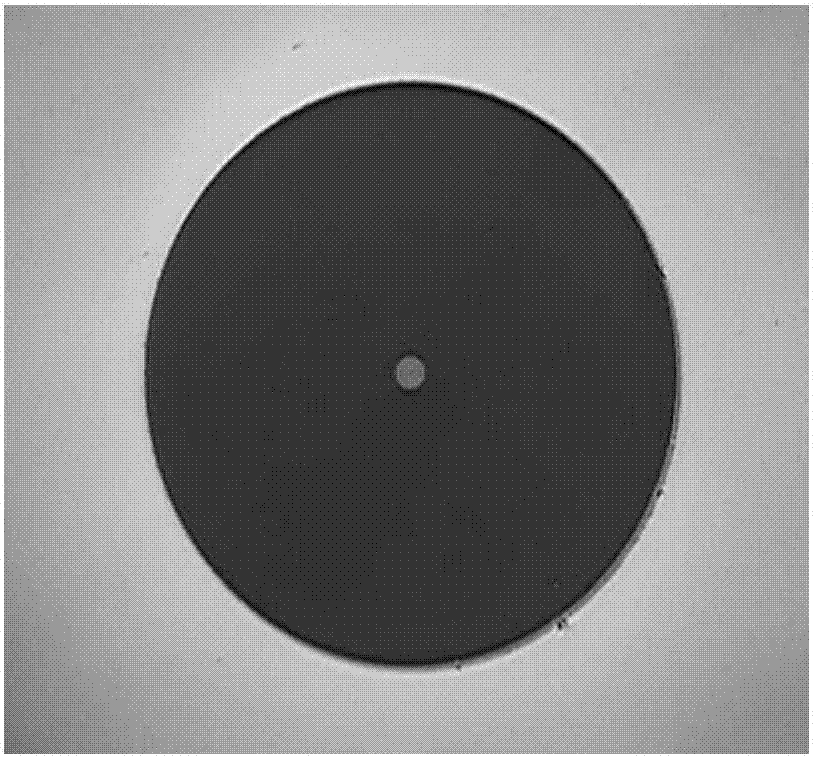

[0031] 2) Soak both ends of the chalcogenide glass optical fiber in a beaker filled with dimethylacetamide. After 8 minutes, the organic plastic coating on the surface of the optical fiber at both ends falls off by itself, exposing a bare fiber with an outer diameter of 240 μm at both ends. Optical fiber, take out the two ends of the optical fiber from d...

Embodiment 2

[0047] Embodiment 2: with the Ge that has PPSU organic plastic coating layer 15 Sb 15 Se 70 Taking chalcogenide glass optical fiber as an example, it is processed into FC type chalcogenide glass optical fiber connector. The processing method includes the following steps:

[0048] 1) Select a section of Ge with a PPSU organic plastic coating 15 Sb 15 Se 70 For chalcogenide glass optical fiber, prepare two ceramic ferrules with spherical end faces. The inner hole diameters of the two ceramic ferrules are both 125 μm, and prepare two sets of conventional connection components required for the assembly of optical fiber connectors;

[0049] 2) Soak both ends of the chalcogenide glass optical fiber in a beaker filled with ether. After 6 minutes, the organic plastic coating layer on the surface of both ends of the optical fiber will fall off by itself, exposing a bare optical fiber with an outer diameter of 120 μm at both ends. Take out the two ends of the fiber respectively fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com