Long-term efficient passive containment cooling system utilizing jetting technique

A passive containment and cooling system technology, applied in the field of containment cooling systems, can solve the problems of low steam condensation efficiency hindering heat export in the containment, so as to promote gas circulation in large spaces, reduce water tank evaporation, and enhance heat transfer effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in more detail below in conjunction with accompanying drawing example:

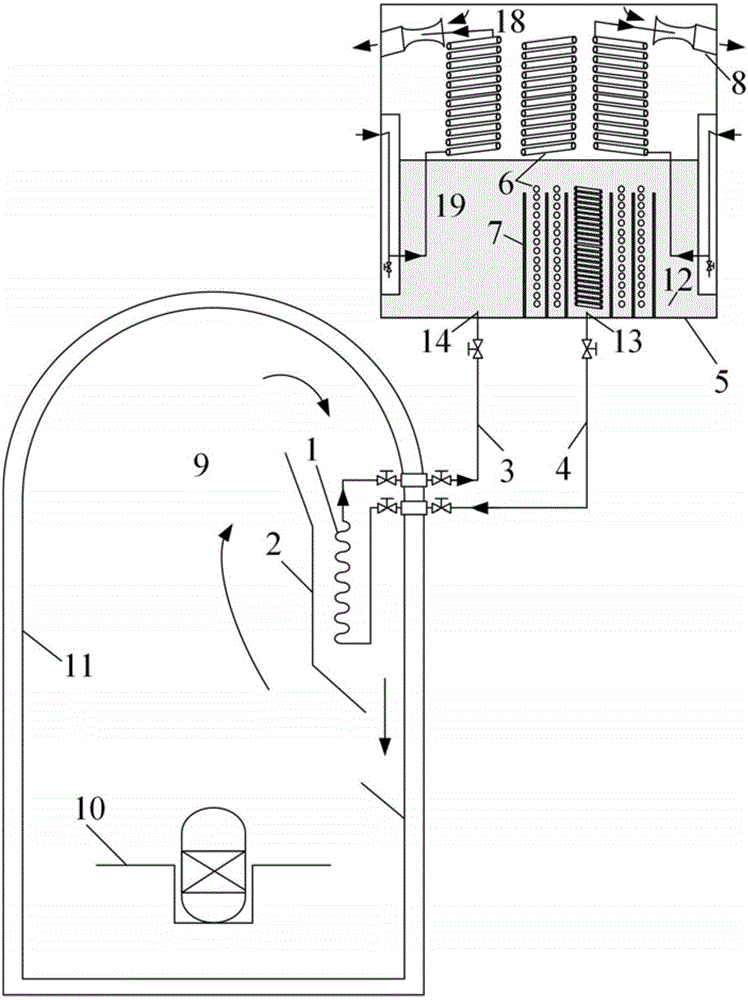

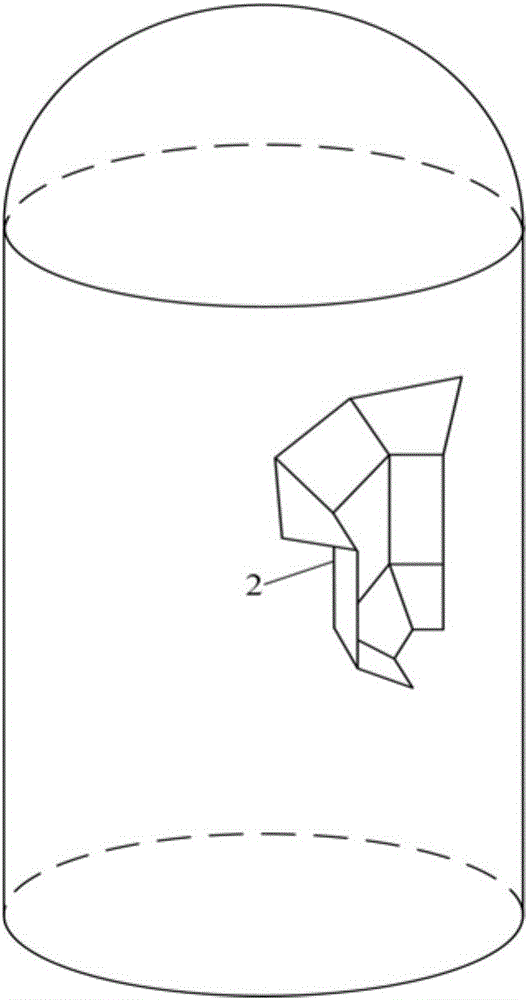

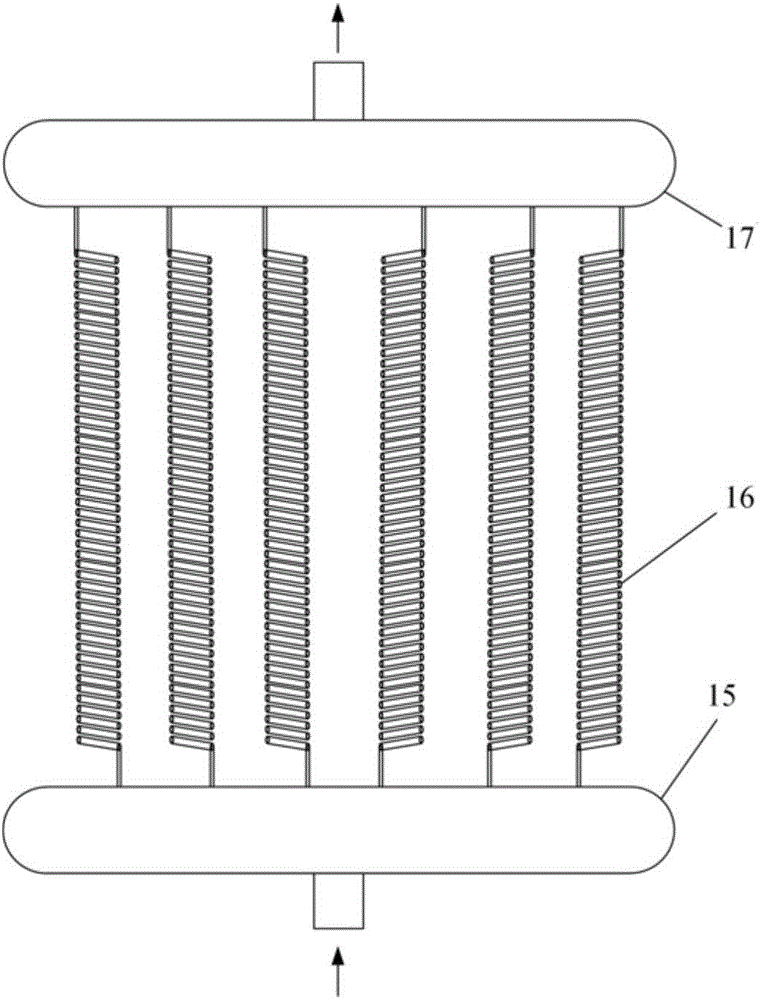

[0039] combine Figure 1-15 , the present invention provides a long-term efficient passive containment heat export system. The system includes a heat exchanger inside the containment vessel 1, a diversion plate 2, an upper pipe section 3, a lower pipe section 4, a replacement hot water tank outside the containment vessel 5, an air cooler 6, a water tank baffle plate 7, a steam-air injection device 8 and Associated pipeline valves. Among them, the heat exchanger 1 inside the containment and the upper and lower pipe sections 3 and 4 constitute the first-stage heat removal system, which uses natural circulation to discharge the heat in the containment into the external water tank of the containment; the air cooler in the external water tank 5 6. The steam-air injection device 8 and its corresponding pipes and valves form the second-stage heat removal system of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com