Large-span cross aisle building method applied to segmental lining tunnels

A horizontal channel and long-span technology, applied in tunnels, shaft linings, tunnel linings, etc., can solve the problems of being unable to be closed into a loop, affecting safety, and large spans of horizontal channels, so as to achieve low structural strength, high safety, and prevent collapse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

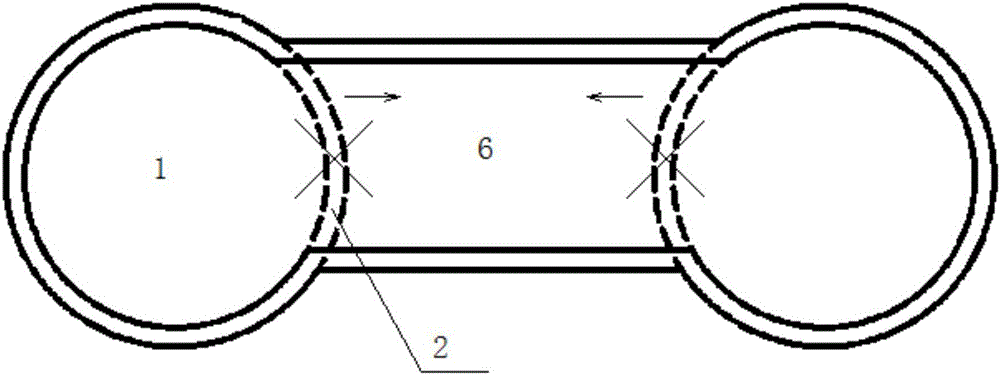

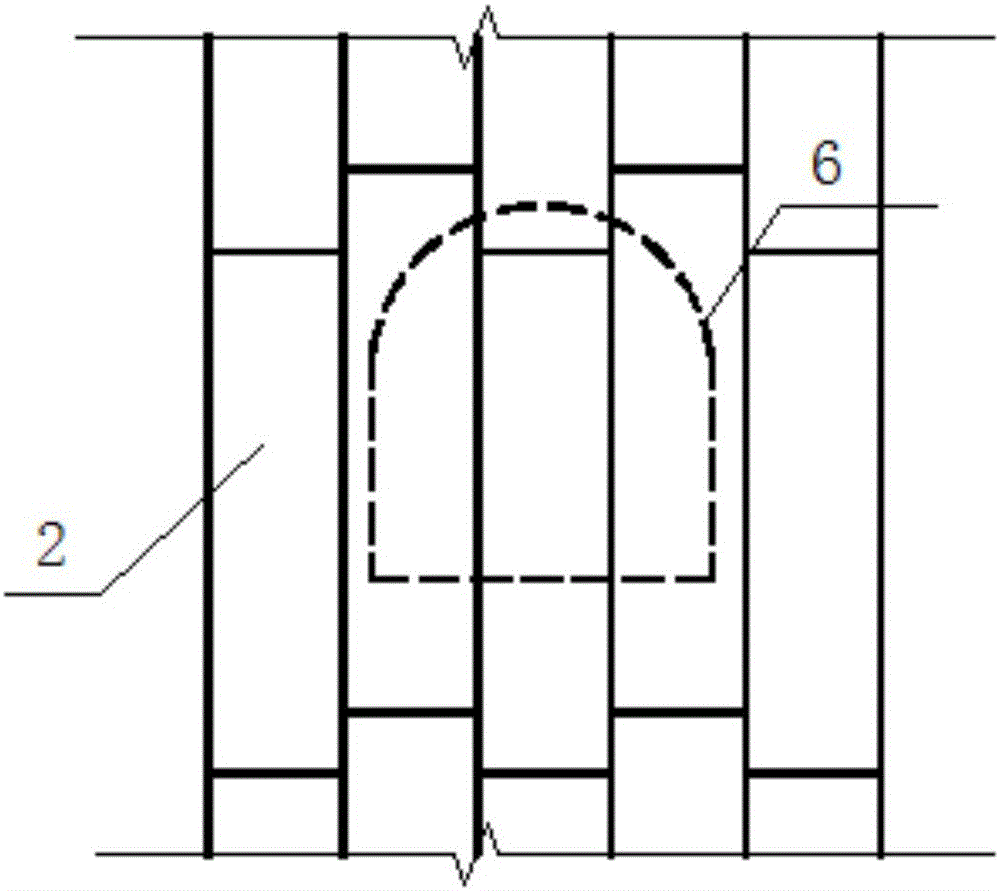

[0026] Example: such as Figure 1 to Figure 5 A method for constructing a long-span cross passage applied to a segment-lined tunnel is shown, including the following steps:

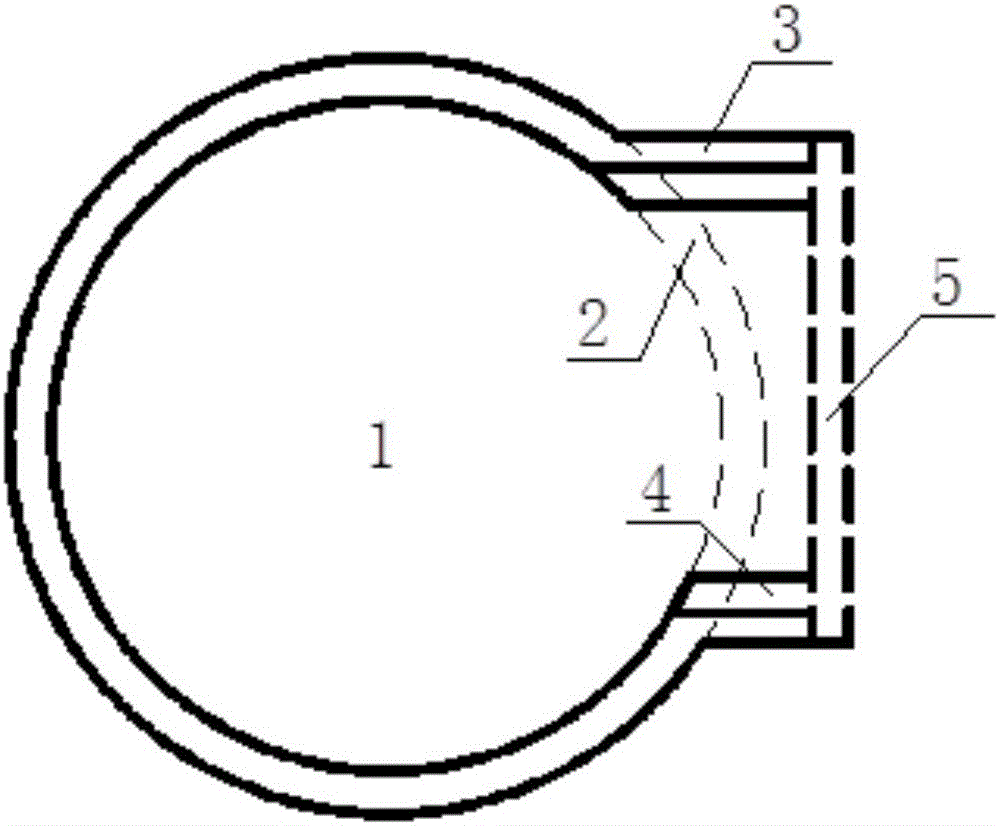

[0027] 1) Construction of the segment-lined tunnel 1, after the structure of the segment-lined tunnel 1 is stabilized and the stratum is temporarily stabilized, at the interface between the transverse channel 6 and the segment-lined tunnel 1 at both ends, the segment-lined tunnel 1 is demolished along the longitudinal direction 1 ~ 2 pieces of segment lining 2, forming a breach;

[0028] 2) Excavate the soil layer at the breach of the segment-lined tunnel 1 toward the direction of the cross passage 6, and build the initial support structure 3 of the cross passage 6 horizontally outwards on the outer edge of the breach, and then install the initial support A temporary sealing wall 5 is built vertically at the outer end of the structure 3, and the horizontal distance between the temporary sealing wall 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com