Pipeline laying structure applied to high-speed geotechnological centrifugal machine

A geotechnical centrifuge and centrifuge technology, applied in the field of centrifuges, can solve the problems of destroying the aerodynamic shape of the rotating arm, increasing the stress value at the opening position, and breaking the pipeline, achieving low overall structural strength, simple installation and disassembly, and guaranteed use. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

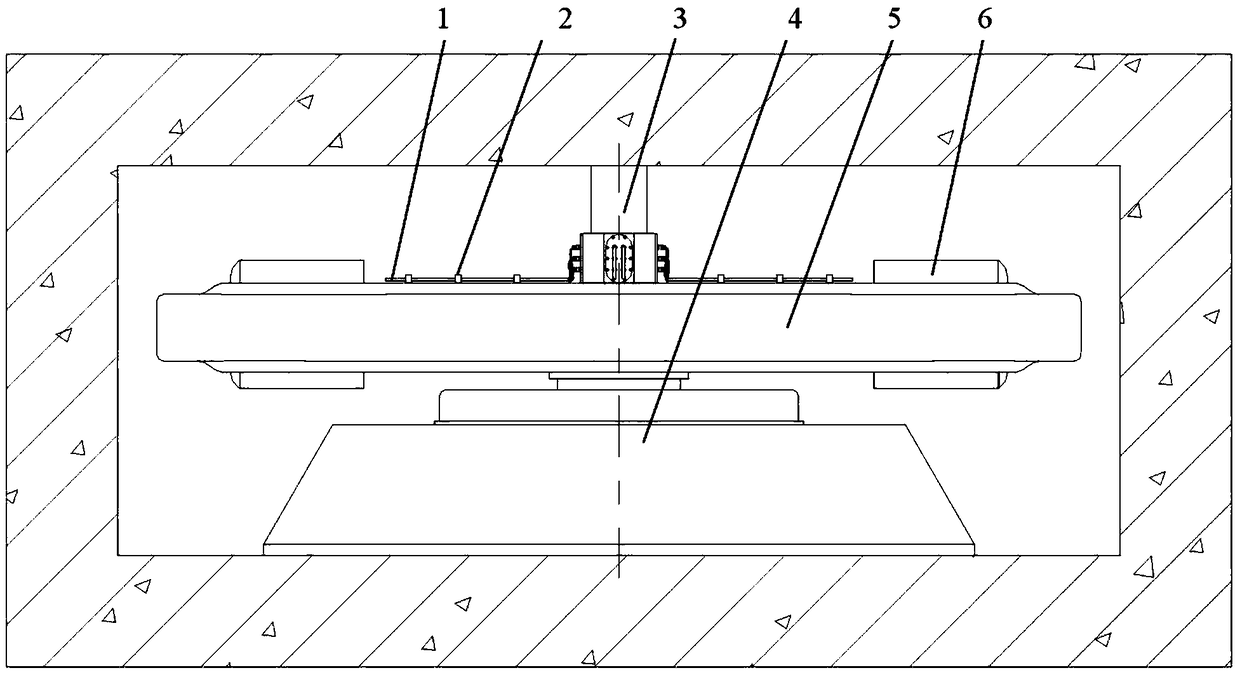

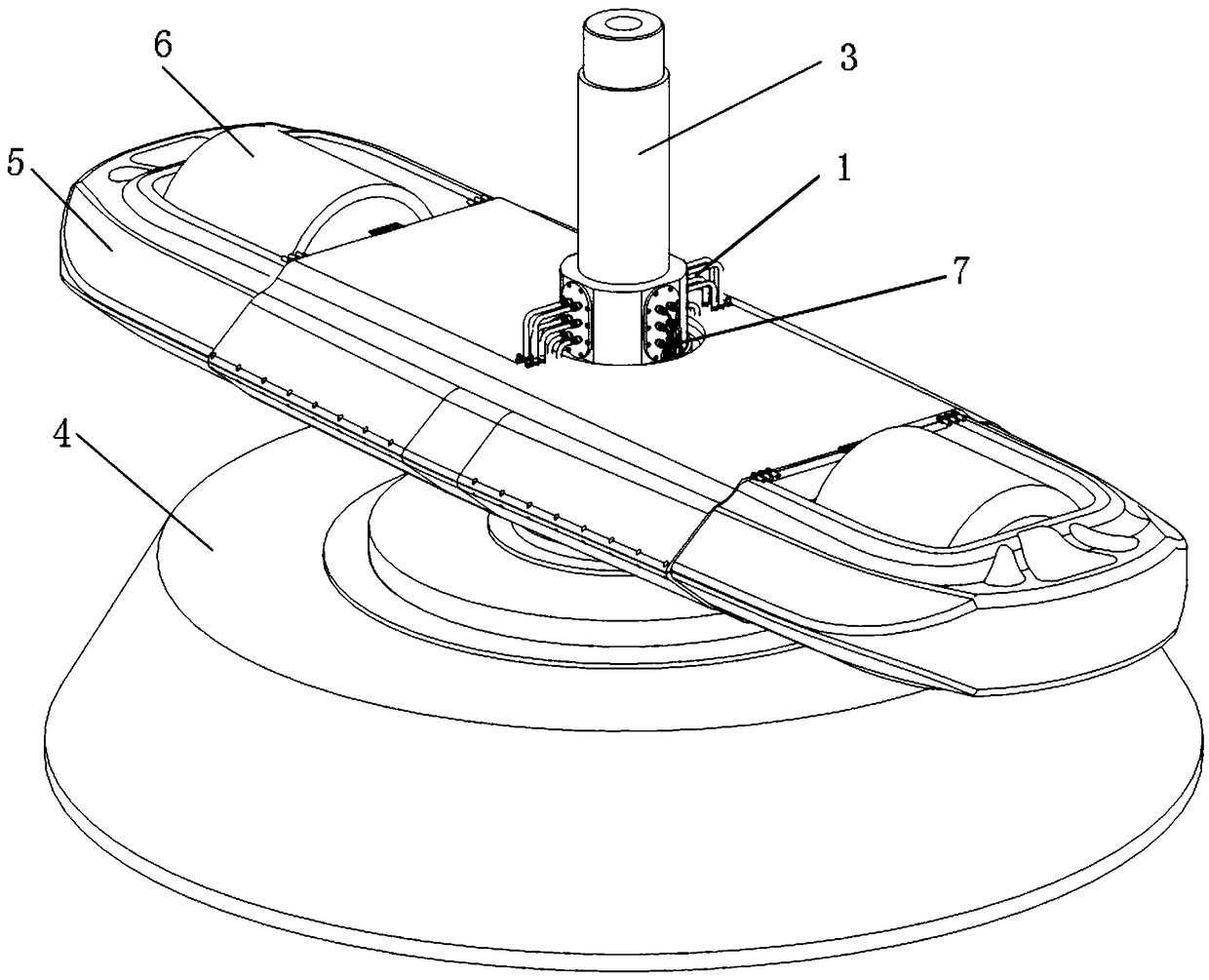

[0051] Example 1, such as figure 2 and image 3 as shown,

[0052] A pipeline laying structure applied to a high-speed geotechnical centrifuge, which is used to supply water, air, and power from the rotating shaft 3 of the centrifuge to the hanging basket 6 of the centrifuge. The pipeline laying structure is tightly fitted on the rotating arm 5 of the centrifuge , the pipeline laying structure is integrally solidified with a pipeline 1 and a cable 7, and the two ends of the pipeline 1 are respectively connected with a pipe joint 11, and the two ends of the cable 7 are respectively connected with a cable plug 13; the pipeline laying structure passes through two pipe joints 11 They are respectively connected to the water supply and air supply interfaces on the rotating shaft 3 and the water supply and air supply interfaces on the hanging basket 6, and the pipeline laying structure is respectively connected to the power supply interface on the rotating shaft 3 and the power sup...

Embodiment 2

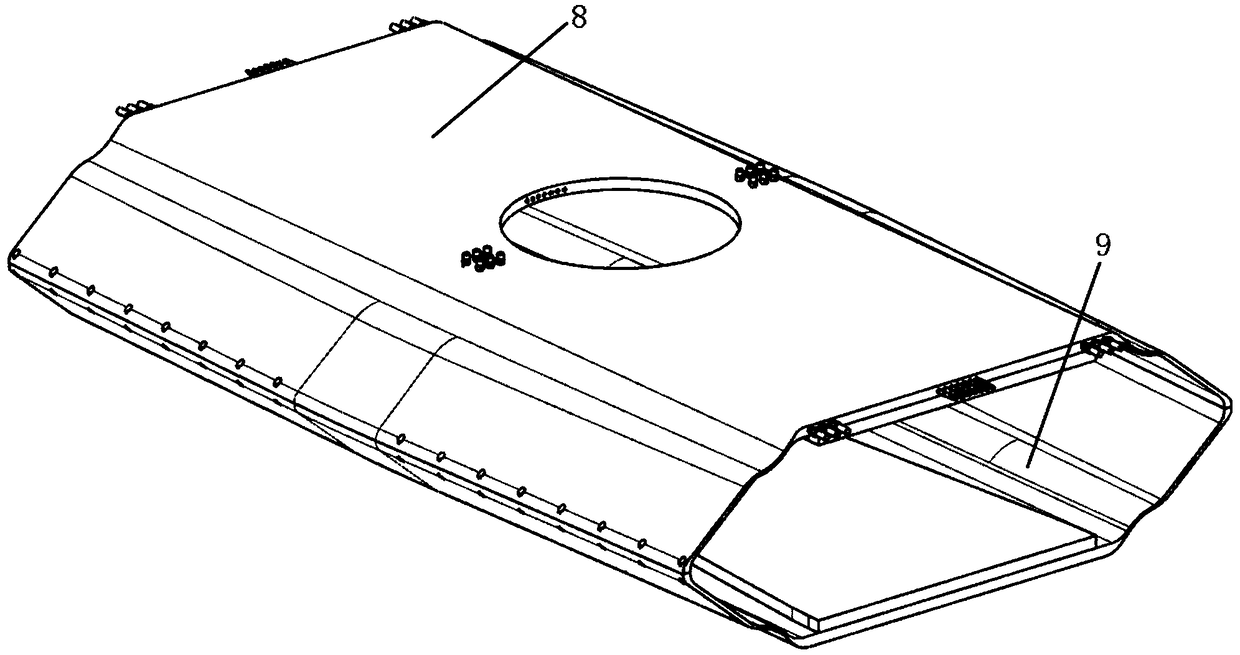

[0054] Example 2, such as image 3 and Figure 4 as shown,

[0055] The difference between this embodiment and embodiment 1 is:

[0056] The pipeline laying structure includes:

[0057] The upper bracket 8; the upper bracket 8 includes a casing 12, the pipeline 1 and the cable 7 are integrally formed inside the casing 12, and the lower surface of the upper bracket 8 casing 12 is attached to the upper part of the rotating arm 5;

[0058] The lower bracket 9; the lower bracket 9 includes a shell 12, the upper surface of the lower bracket 9 shell 12 is attached to the lower part of the rotating arm 5, and the middle part of the upper bracket 8 shell 12 and the lower bracket 9 shell 12 is provided with a hole for the shaft 3 to pass through Screw mounting holes are reserved on both sides of the upper bracket 8 and the lower bracket 9, and the two sides of the upper bracket 8 shell 12 are respectively connected with the two sides of the lower bracket 9 shell 12 through a plurali...

Embodiment 3

[0061] Example 3, such as image 3 as shown,

[0062] The difference between this embodiment and embodiment 2 is:

[0063] The surfaces of the upper bracket 8 and the lower bracket 9 are smooth and continuous.

[0064] The shells 12 are molded and solidified in a special mold, so the outer surfaces of the upper bracket 8 and the lower bracket 9 are smooth and continuous, and the aerodynamic resistance is small, thereby reducing the wind resistance of the geotechnical centrifuge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com