Concrete drilling and sampling machine

A drilling sampling machine and concrete technology, applied in the field of laboratory equipment, can solve the problems of difficulty in taking out samples, waste of cooling water, limiting the working environment of drilling rigs, etc., and achieve the effects of avoiding drill bit damage, reducing pollution, and preventing splashing around

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

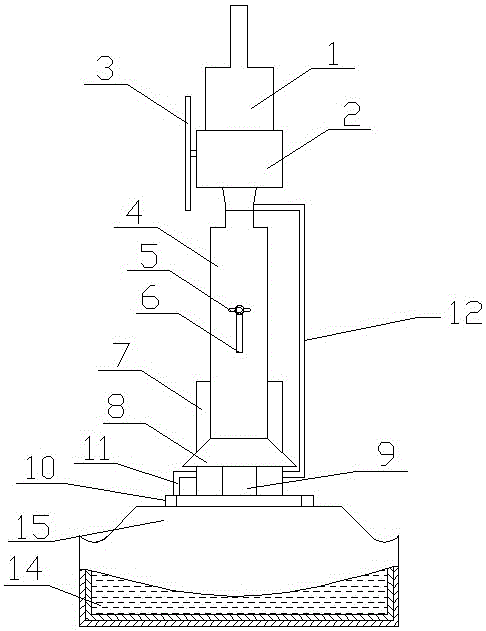

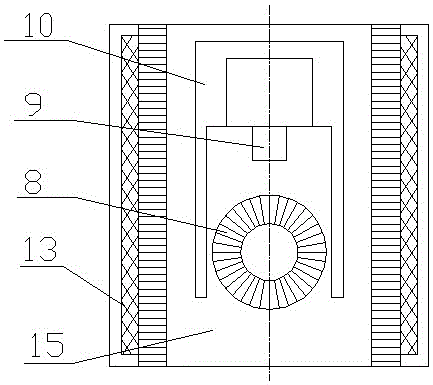

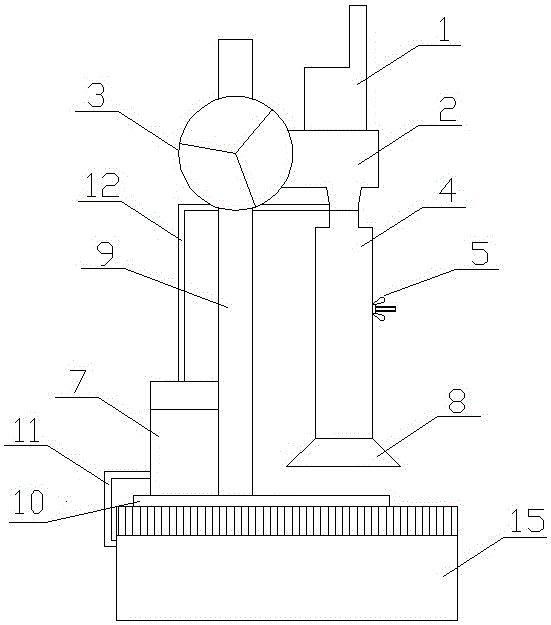

[0029] refer to Figure 1-Figure 7 , a concrete drilling sampler in the present embodiment, which includes a drilling machine, a platform 15, a drill bit 4, a coring device 5, a cooling circulation device and a splash guard 8, an inner cavity is arranged in the middle of the platform 15, and the top surface of the platform 15 Several flow holes are set to communicate with the inner cavity, the flow holes of the platform 15 are provided with filter screens 13, and slopes are arranged on the side of the platform 15, so that cooling water flows into the water tank 14 through the flow holes, and the drilling rig is placed on the platform 15. The upper end of the drill bit 4 is fixedly connected with the power output shaft of the drilling rig, the coring device 5 is placed in the drill bit 4, and one end of the coring device 5 extends out of the drill bit 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com