Motor stator punching sheet machining method

A processing method and motor stator technology, applied in the direction of motors, metal processing equipment, motor generators, etc., can solve the problems of poor heat dissipation performance of stator punching sheets, poor structural fastness, inconvenient stacking, etc., and achieve low product damage rate , easy maintenance and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

[0046] This specific embodiment adopts following technical scheme: comprise the following steps:

[0047] S1. Unwind the selected raw materials that meet the requirements.

[0048] S2. After the raw material is unrolled, it is fed to the punching machine through the feeding mechanism.

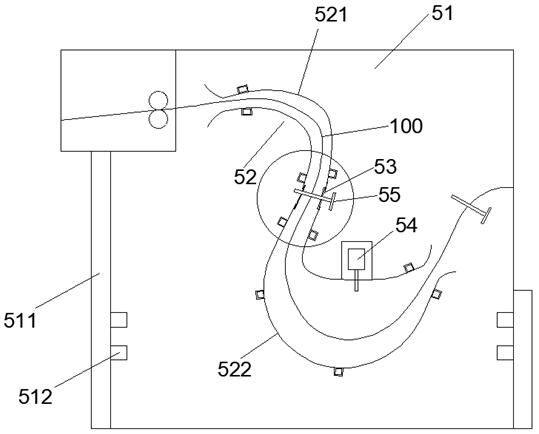

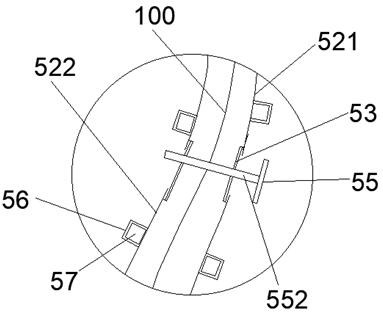

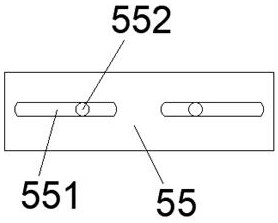

[0049] like figure 1 As shown, the feeding mechanism includes a pulling roller, a mounting frame 51 and a feeding track 52, the pulling roller pulls the raw material 100 into the feeding track 52, the feeding track 52 is installed on the mounting frame 51, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com