Automatic batch workpiece coating system

A workpiece and batch technology, applied in the field of automatic batch workpiece coating system, can solve the problems of low work efficiency, achieve the effect of reducing shaking, reducing manual participation, and avoiding skew and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

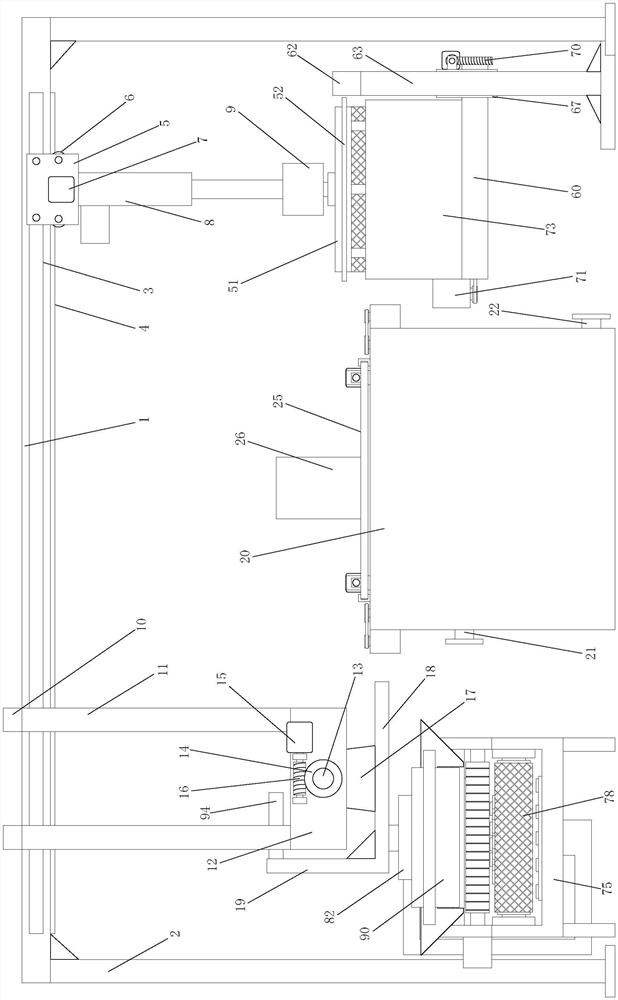

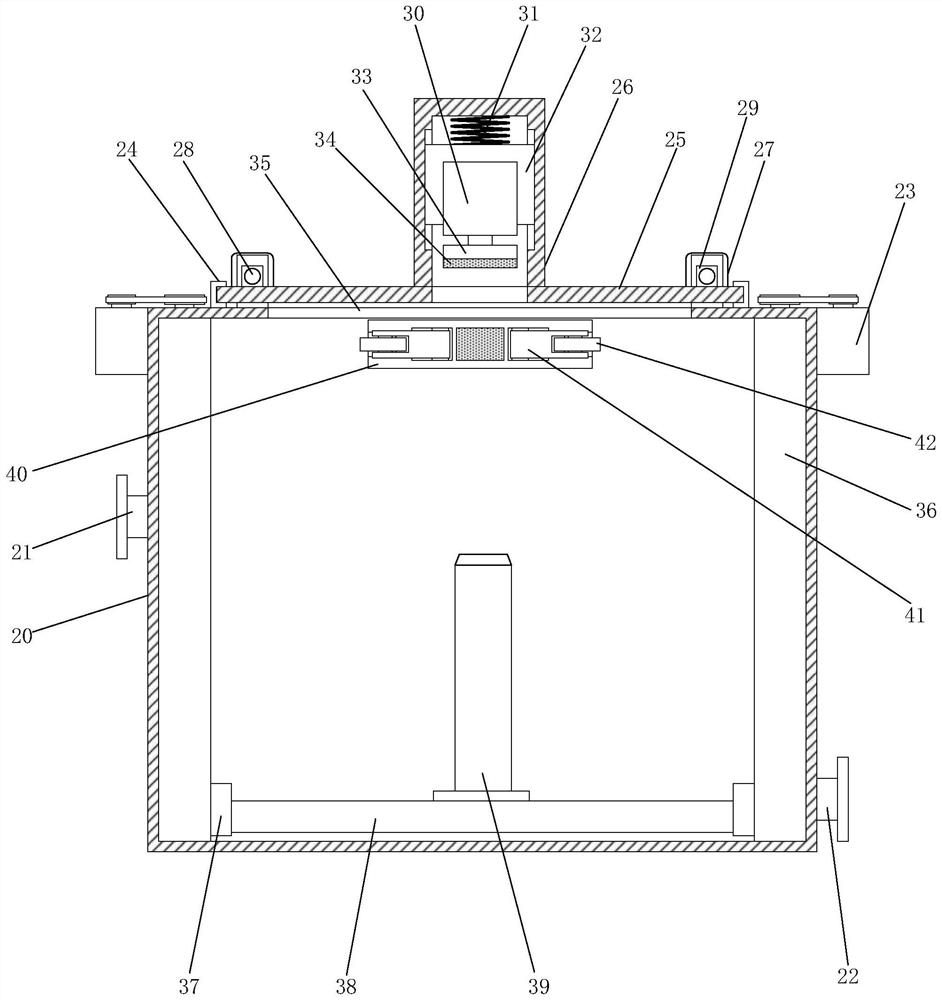

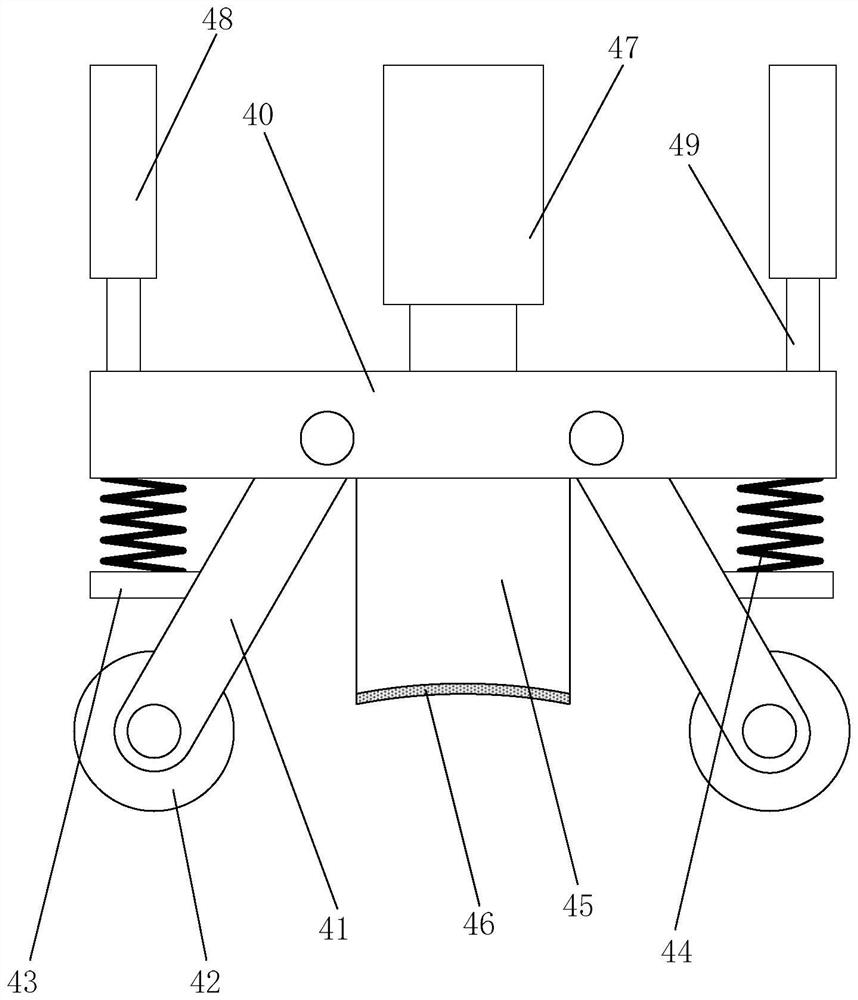

[0024] Such as Figure 1-6 As shown, the automatic batch workpiece coating system disclosed in the present invention includes: a hanging transport device, a workpiece carrying device, a material loading and shaking device, a lifting coating device, a blanking and dumping device, and a surface baking device; the hanging transport device includes Support frame and suspension transport mechanism;

[0025] The loading and shaking device is located at the feeding station of the lifting coating device, which is used to place the workpiece carrying device and shake the batch of workpieces carried in the workpiece carrying device; the lifting and coating device is used to load the workpiece carrying device The batch workpieces are coated and dried; the unloading and dumping device is located at the unloading station of the lifting coating device and above the surface baking device, and is used to accept the workpiece carrying device and dump the materials carried in the workpiece carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com