Stack column type filling formwork and using method thereof

A formwork and stacking column technology, which is applied in the field of stacking column filling formwork and its application method, can solve the problems of occupying operation time, inability to guarantee the strength in the later stage, and difficult control of the shape, so as to reduce the compression amount in the later stage and reduce the workload of formwork removal , uniform strength and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

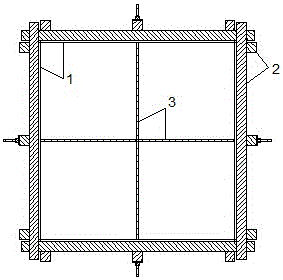

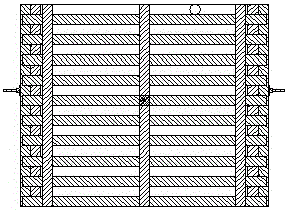

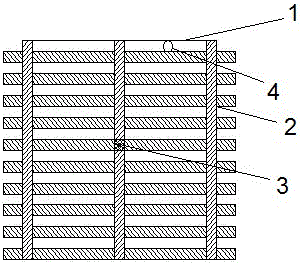

[0047] 1. When the thickness of the roof is greater than 5m, the strength is greater than 100MPa and the integrity is good, calculate the initial caving step distance L according to the engineering conditions 1 , and use the safety factor method and branch area distribution method to determine the filling distance L' and the side length a of the filling cylinder (a cube structure); where: L'=L 1 -a, h is the thickness of the direct top, R T is the direct top tensile strength, q is the direct top overlying load, f cu is the compressive strength of the packed column, k 1 、k 2 is the safety factor; the calculated filling distance L at this time 1 Larger, the size a of the filling cylinder is larger, and the length of one side is generally greater than 3m;

[0048] 2. Design the length a' of the filling formwork according to the size a of the filling cylinder. When the size of one side of the filling cylinder is greater than 3m, the filling formwork is designed in sections a...

Embodiment 2

[0053] 1. When the thickness of the roof is less than 5m, the strength is less than 100MPa, and the integrity is poor, calculate the periodic collapse step distance L according to the engineering conditions 2 , and use the safety factor method and branch area distribution method to determine the filling distance L' and the side length a of the filling cylinder (a cube structure); where: L'=L 2 -a, h is the thickness of the direct top, R T is the direct top tensile strength, q is the direct top overlying load, f cu is the compressive strength of the packed column, k 1 、k 2 is the safety factor; at this time, the calculated filling distance L' is small, the filling column size a is small, and the length of one side generally does not exceed 3m;

[0054] 2. Design the filling template length a' according to the filling cylinder size a, and the template height is determined with the mining height;

[0055] 3. Transport the prepared filling support frame to the filling workin...

Embodiment 3

[0059] 1. When the thickness of the roof is greater than 5m, the strength is greater than 100MPa and the integrity is good, calculate the initial collapse step distance L according to the engineering conditions, and use the safety factor method and branch area distribution method to determine the filling distance L' and the filling column ( is the side length a of the cube structure); where: L'=L 1 -a; h is the thickness of the direct roof, R T is the direct top tensile strength, q is the direct top overlying load, f cu is the compressive strength of the packed column, k 1 、k 2 is the safety factor; at this time, the calculated filling distance L is relatively large, the dimension a of the filling cylinder is relatively large, and the length of one side is generally greater than 3m;

[0060] 2. Design the length a' of the filling formwork according to the size a of the filling cylinder. When the size of one side of the filling cylinder is greater than 3m, the filling form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com