Method for filling gob

A goaf filling technology, applied in filling, mining equipment, earth square drilling and mining, etc., can solve problems such as incomplete filling, inappropriate selection and proportion of paste materials, high slurry mass fraction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

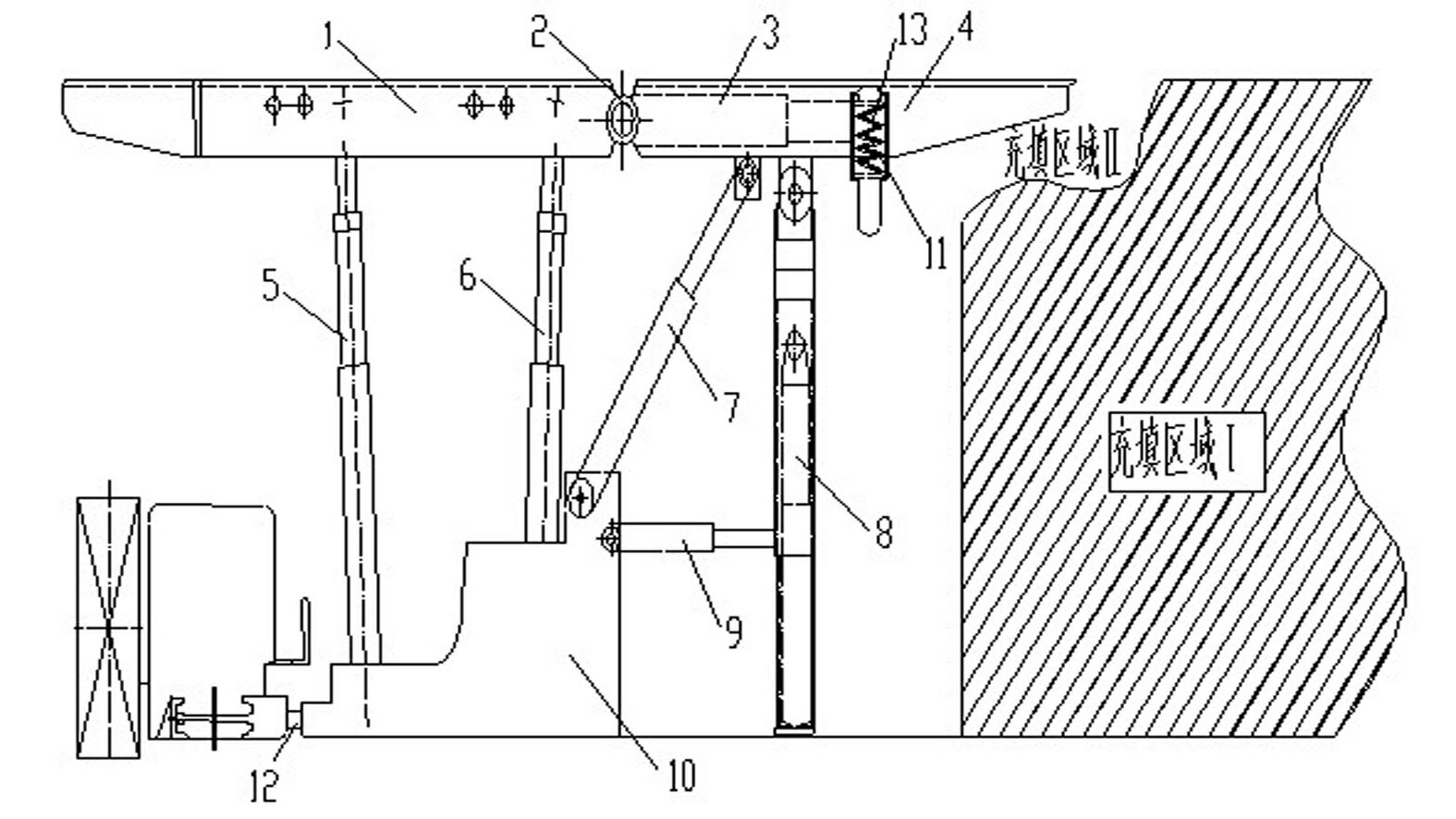

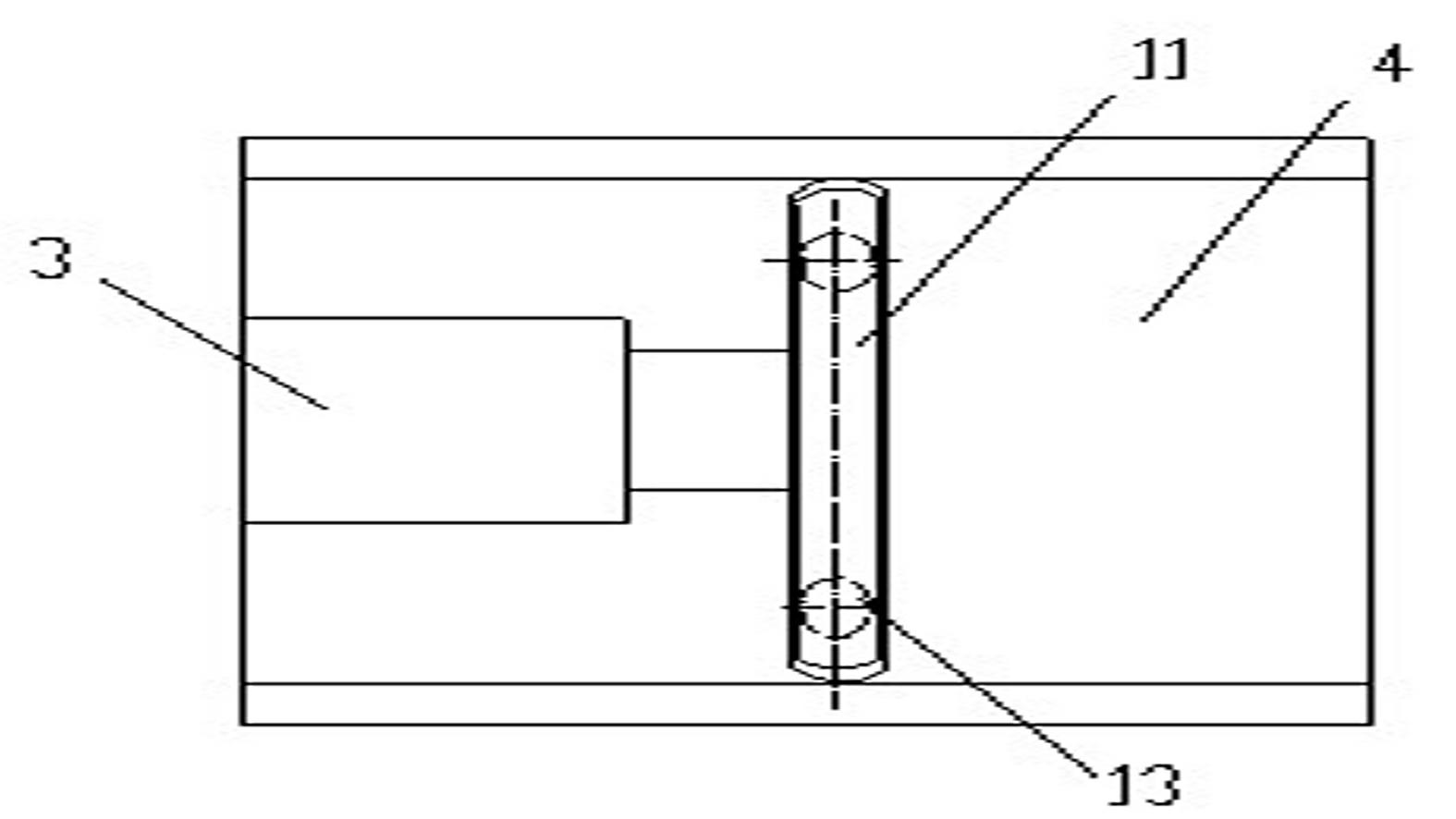

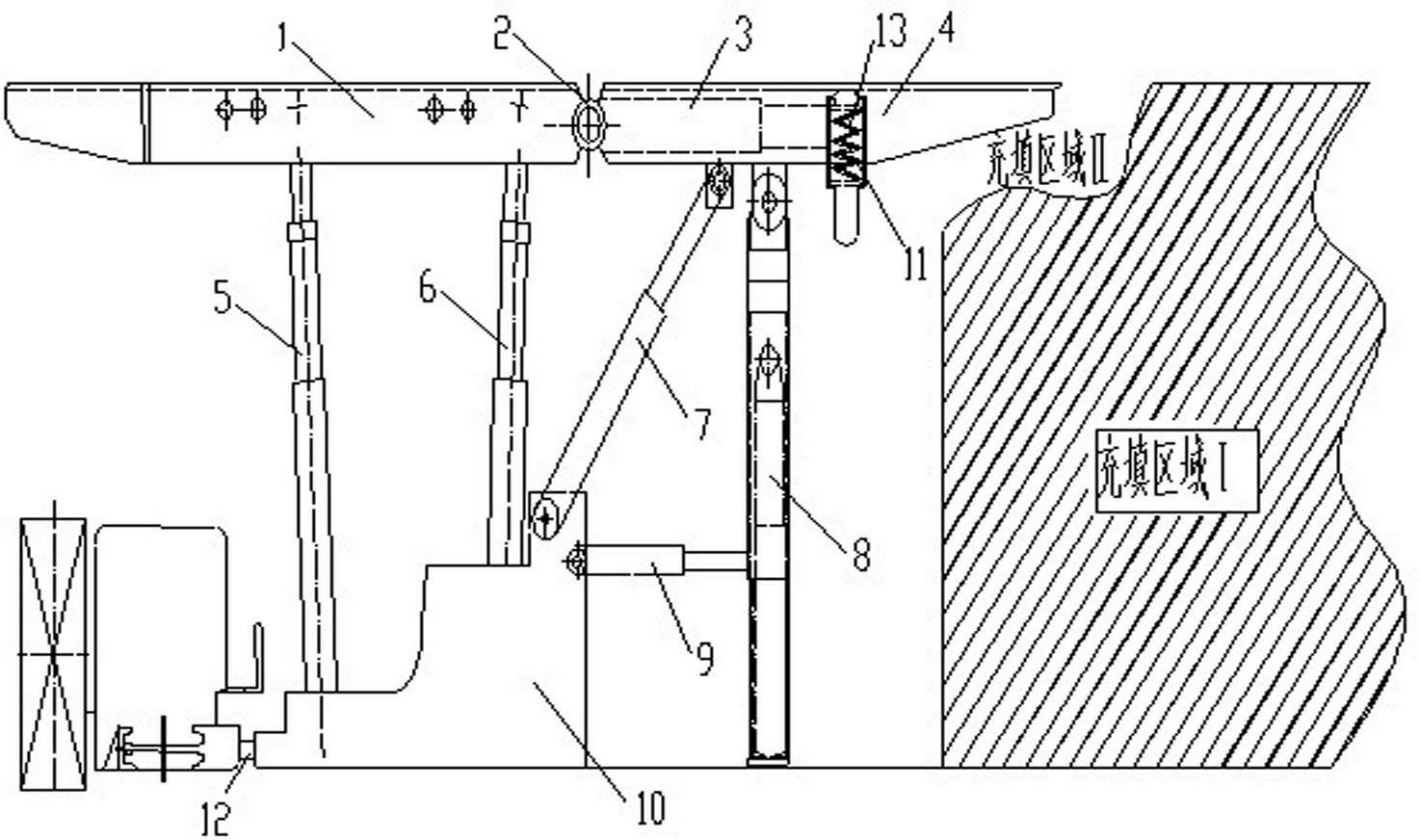

[0017] Specific embodiments of the present invention are described in further detail below:

[0018] Implementing a method for filling the goaf provided by the present invention is a method for filling the goaf in the existing filling mining method. The paste material in the mined-out area, in order to achieve the purpose of enriching the goaf, the specific implementation process is as follows:

[0019] In order to ensure the smooth implementation of filling mining, a special hydraulic filling support for fully mechanized mining is designed. This support should meet the following basic requirements: (1) Supporting the roof of the coal mining operation space of the working face. It is consistent with the requirements for support in the face of ordinary fully mechanized mining. With full filling, there will be no periodic pressure on the filling mining face, and the requirement for the resistance of the working face of the filling support is small. The support strength is req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com