Water-lubricated bearing for pump and water guiding tank molded line optimizing method

A water-lubricated bearing and optimization method technology, applied in the direction of sliding contact bearings, bearings, bearing components, etc., can solve the problems of high bearing pressure, thinning of liquid film, etc., and achieve the effect of reducing wear loss and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

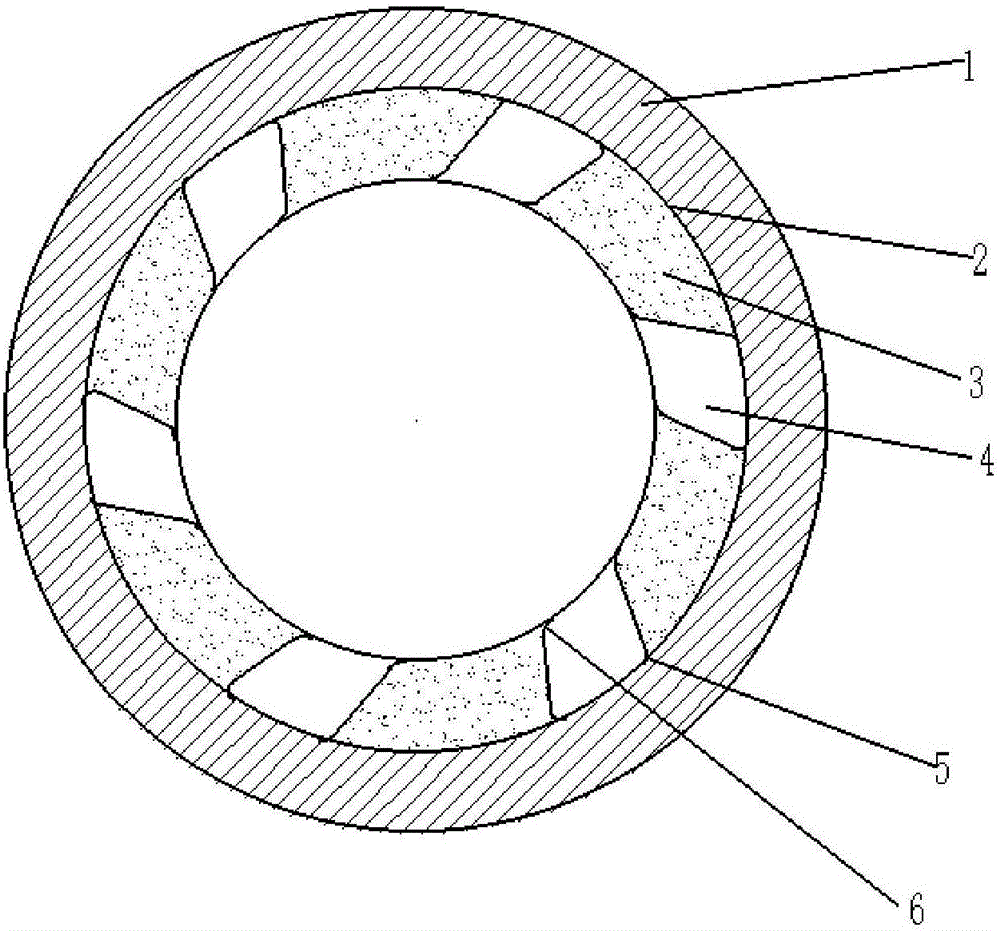

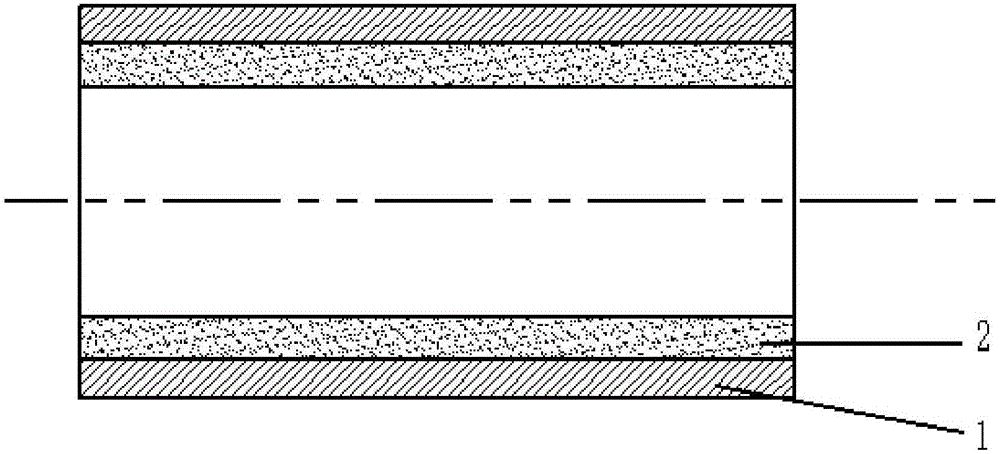

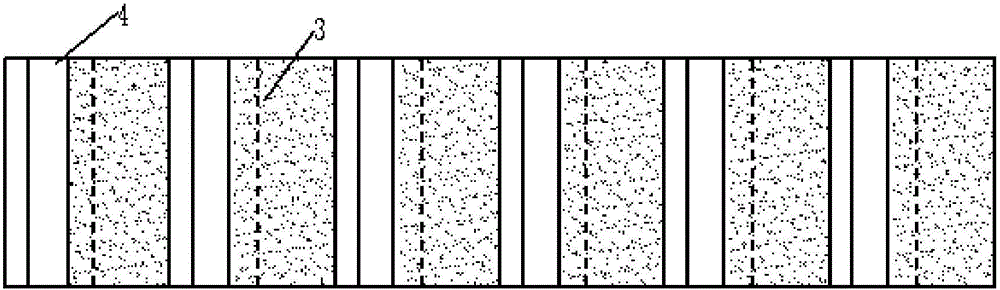

[0028] The present invention is a pump water lubricated bearing and a method for optimizing the profile of the water guide groove, combining figure 1 , figure 2 , image 3 . The steps of the method include:

[0029] Step 1: Water lubricated bearing structure

[0030] The water-lubricated bearing consists of an outer alloy sleeve 1 and a rubber inner sleeve 2. Wherein, the outer alloy sleeve 1 constitutes the outer wall of the water-lubricated bearing. The rubber inner sleeve 2 constitutes the inner wall of the water-lubricated bearing. The outer side of the rubber inner bushing 2 and the inner side of the outer alloy sleeve 1 are adhered together to form a water-lubricated bearing, and its overall cross-sectional shape is annular. Wherein the rubber inner nest 2 includes a water guide groove 4 and a table area 3 . The inner nest 2 formed in this way is formed by alternating arc-shaped platform areas 3 and arc-shaped water guide grooves 4 with uniform thickness. The thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com