Construction method for dealing with slag accumulation in large-diameter slurry shield silo

A construction method and the technology of the shield bin, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve problems such as mud cake, tool wear, and reduced excavation efficiency, so as to reduce wear loss, improve excavation efficiency, and ensure construction The effect of quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

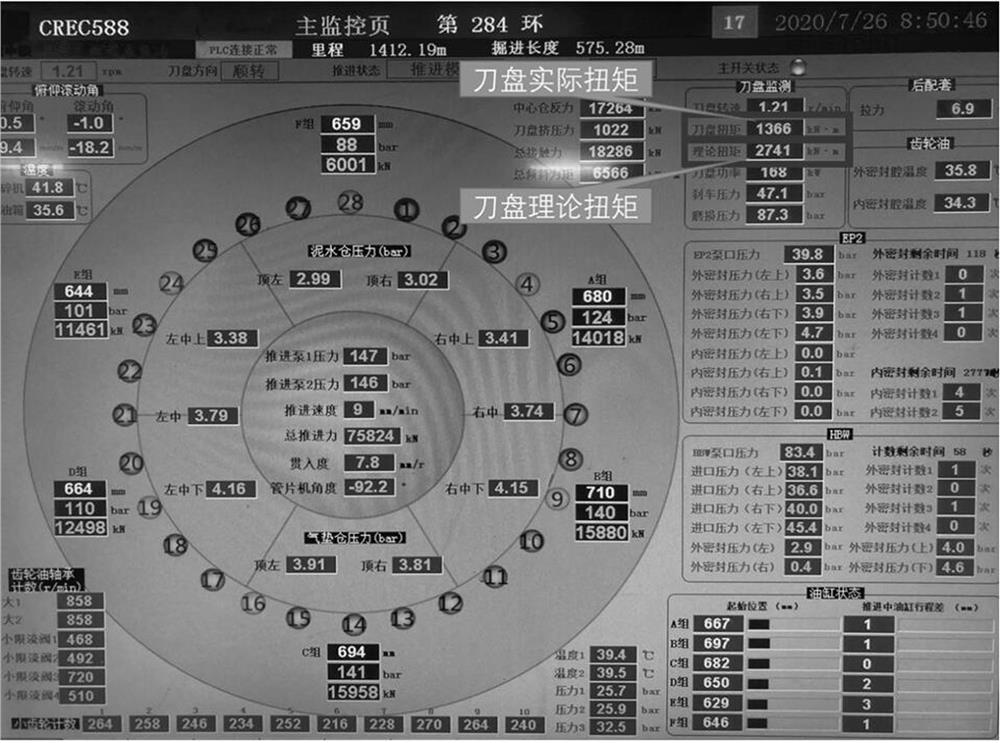

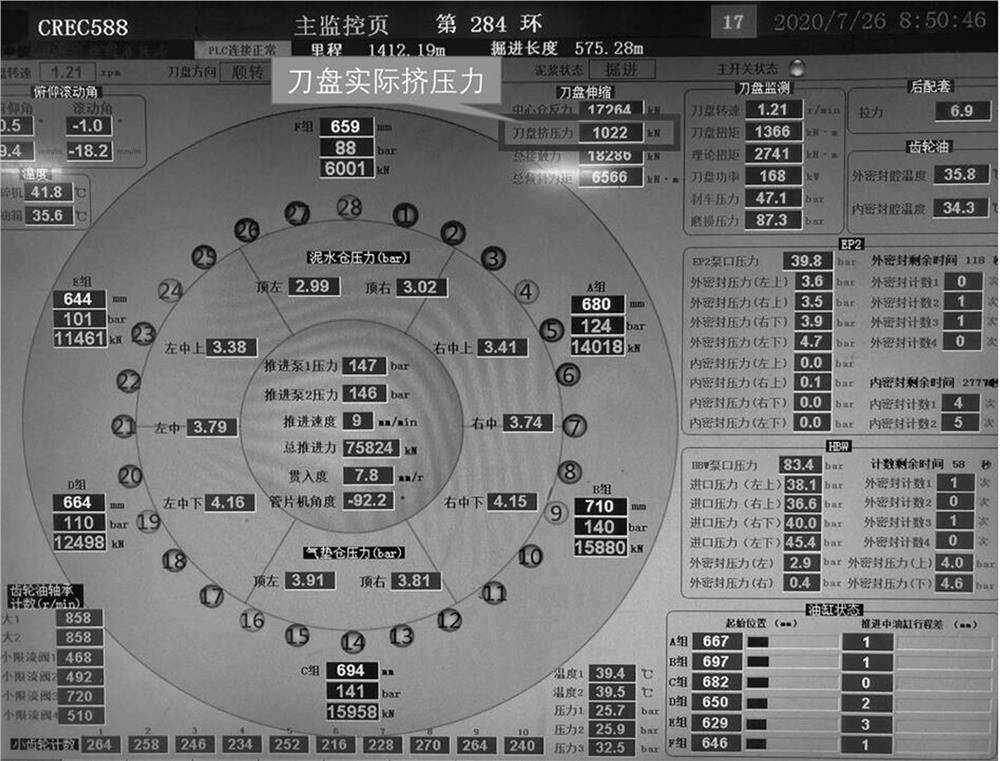

[0059] Example 1: The application practice of "three-in and three-out" warehouse washing in the Chunfeng Tunnel Project

[0060] The Chunfeng Tunnel Project uses a mud-water balance China Railway No. 588 shield machine. The maximum excavation diameter of the shield machine is 15.80m. The inner diameter is φ13.9 meters, and the segment width is 2 meters.

[0061] The Chunfeng Tunnel project line has successively passed through Hongling Interchange, the entrance and exit passage of Metro Line 9, Baoan South Road Interchange, Buji River, Chuanbu Bridge, and Chunfeng Road Elevated; Shenzhen Customs dormitory area and Datan Building, Guangshen Hotel, Guangzhou-Shenzhen Railway Joint Road and Shenzhen Station, Metro Line 1 Luohu Station; pass through the border inspection dormitory area and Wenjindu Port. In order to ensure that the actual axis of the tunnel is consistent with the design axis, and to ensure the quality of segment assembly, the tunnel will not leak water and the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com