Method for preparing bismuth ferrite powder by microwave hydrothermal method

A microwave hydrothermal method, bismuth ferrite technology, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of poor experimental repeatability, rough powder surface, uneven concentration, etc., and achieve process control. Simple, short process cycle, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: select 0.487g FeCl for use 3 ·6H 2 O, 0.873g Bi(NO 3 ) 3 ·5H 2 After O is dissolved in 20ml of ethylene glycol as a raw material to form a mother salt solution, it is dripped into 200mL of diluted ammonia solution (concentration is 0.3mol / L) under stirring conditions, and the titration rate is less than 2mL / min. After the completion, the stirring was continued for 0.5 h, and the precipitate obtained by the reaction was repeatedly washed with deionized water until the supernatant was neutral, aged for 7 days, and the supernatant was removed to obtain a hydrothermal reaction precursor.

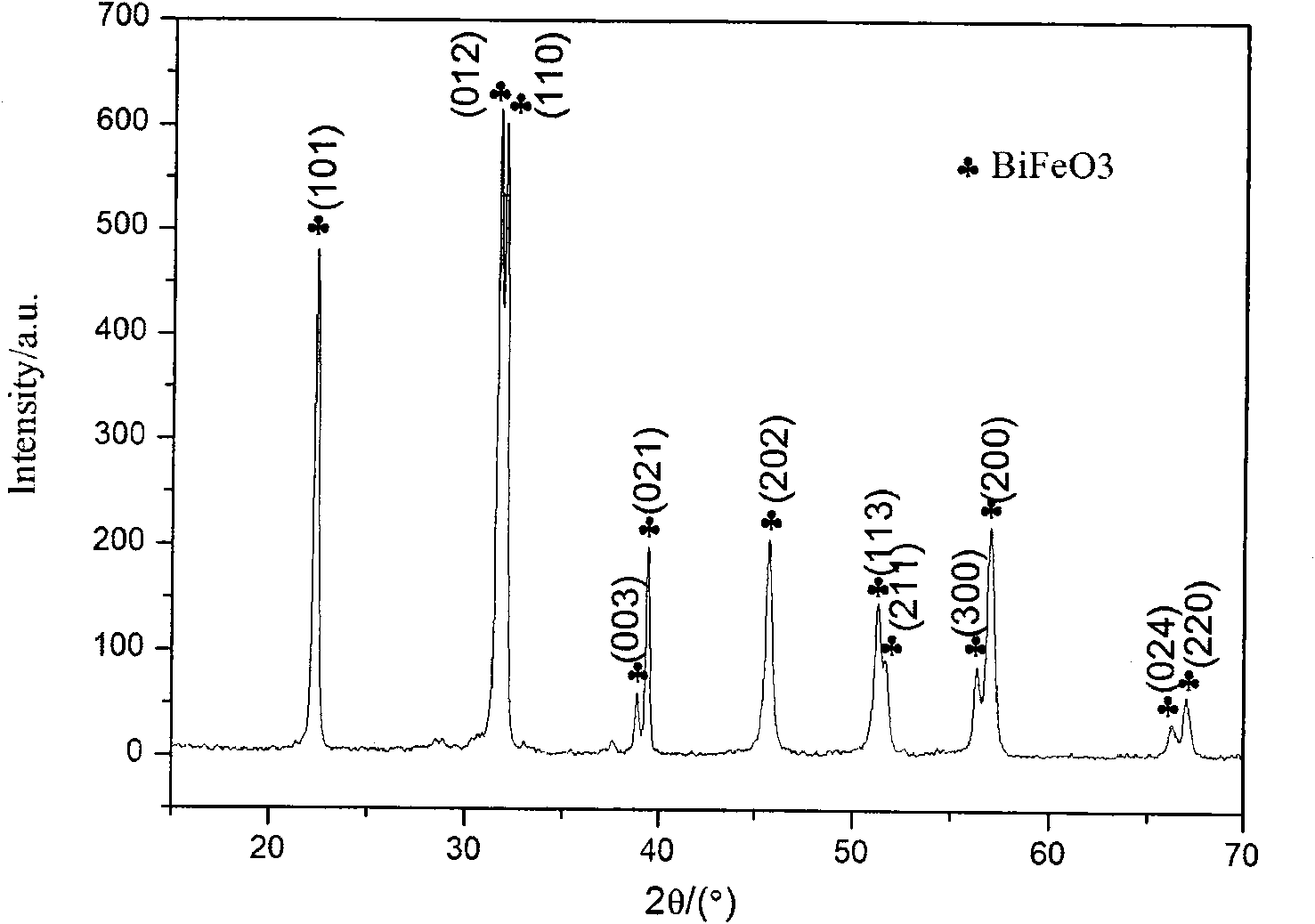

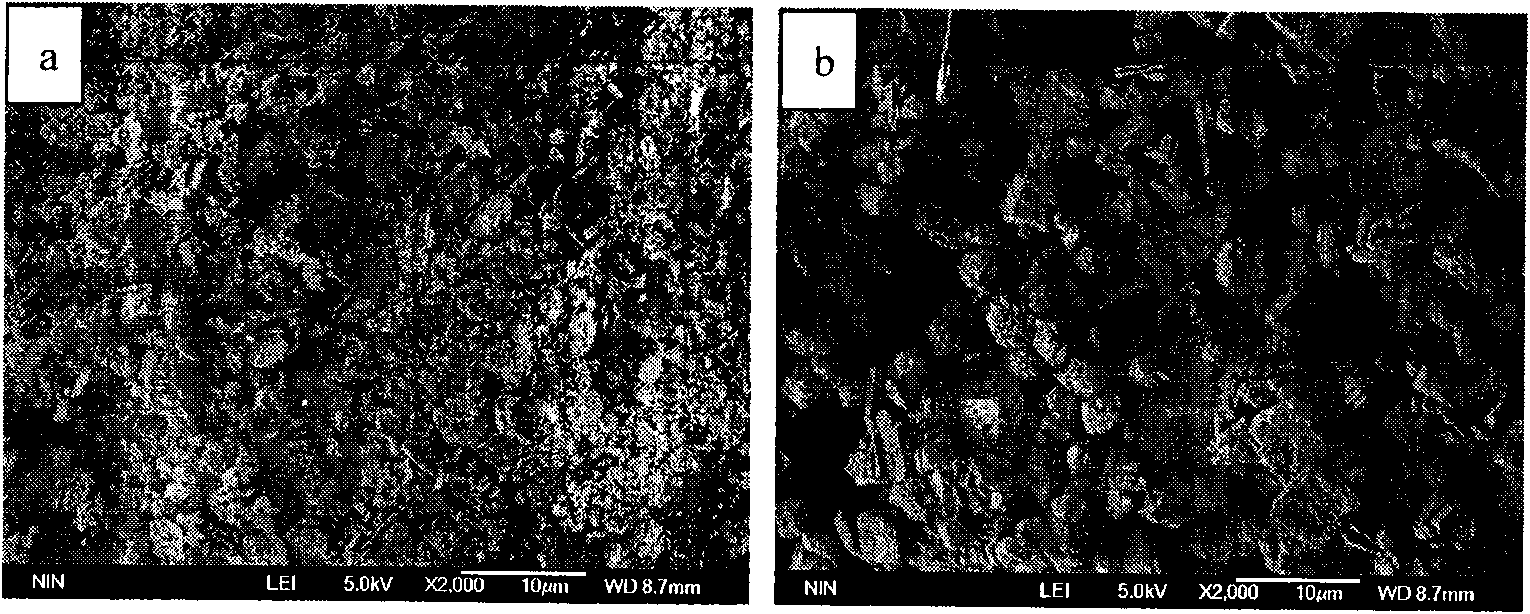

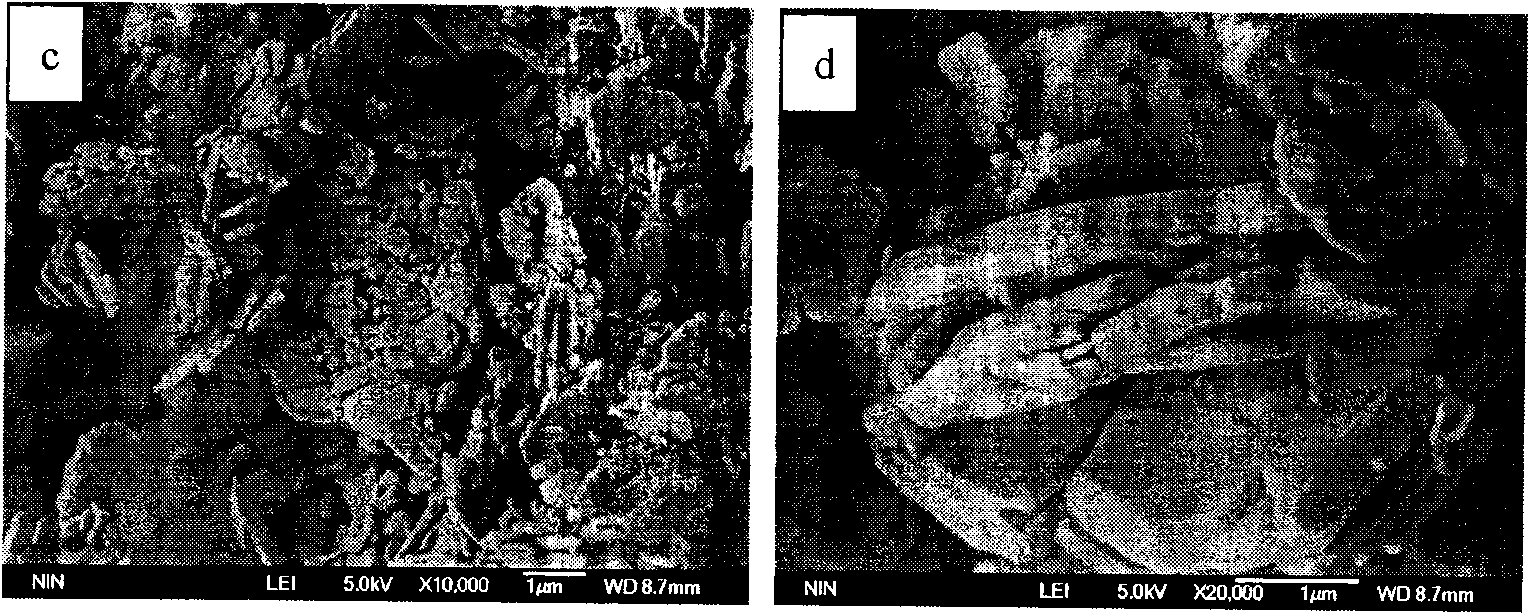

[0030] Move the precursor (60ml) to a microwave hydrothermal kettle (90ml), add 0.05mol / L KOH as a mineralizer, and in the microwave hydrothermal instrument, control the temperature at 200°C and the pressure at about 1.5Mpa, and react for 30min respectively. After 40 minutes and 50 minutes, the product was taken out and washed with deionized water until neutral, and fina...

Embodiment 2

[0037] Embodiment 2: select 0.487g FeCl for use 3 ·6H 2 O, 0.873g Bi(NO 3 ) 3 ·5H 2 After O is dissolved in 20ml of ethylene glycol as a raw material to form a mother salt solution, it is dripped into 200mL of diluted ammonia solution (concentration is 0.3mol / L) under stirring conditions, and the titration rate is less than 2mL / min. After the completion, the stirring was continued for 0.5 h, and the precipitate obtained by the reaction was repeatedly washed with deionized water until the supernatant was neutral, aged for 7 days, and the supernatant was removed to obtain a hydrothermal reaction precursor.

[0038] Move 60ml of the precursor to a microwave hydrothermal kettle (90ml), add 0.05mol / L KOH as a mineralizer, and control the temperature at 160°C, 170°C, 180°C, 190°C and 200°C in the microwave hydrothermal instrument After reacting for 50 minutes, the product was taken out and washed with deionized water until neutral, and finally washed with absolute ethanol three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com