Novel method for proportioning ore grinding media

A grinding medium and ore feeding technology, which is applied in the field of adding grinding medium to large ball mills, can solve the problems of poor crushing performance and poor grinding ability, and achieve the effects of increasing production rate, improving grinding efficiency and reducing production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] For ∮5030×6700mm overflow ball mill:

[0041] 1) The composition of the ore feeding particle size of the ball mill is: the part of the ore feeding particle size of the ball mill that is less than 12mm must reach more than 93% of the total particle size

[0042] 2) The diameters of the grinding media of two different diameters are 120mm and 100mm steel balls,

[0043] 3) The weight ratio of steel balls with a diameter of 120mm and 100mm is 1:1,

[0044] 4) The filling rate of the grinding medium of the ball mill remains at 40%,

[0045] 5) The amount of grinding media added to the ball mill is 5 tons each time, the ball feeding cycle is once a day, and the diameters are 2.5 tons of 120mm and 100mm steel balls.

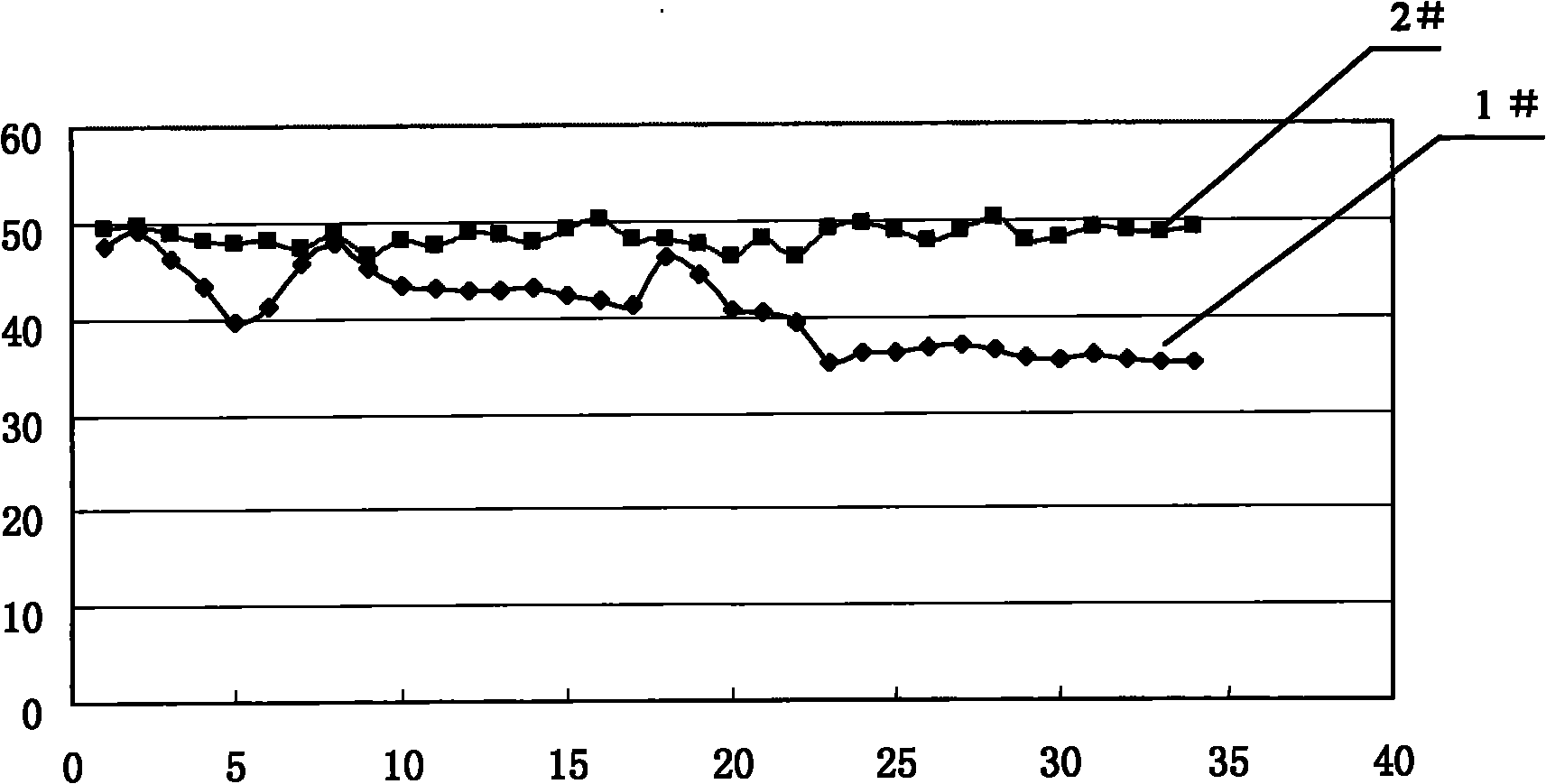

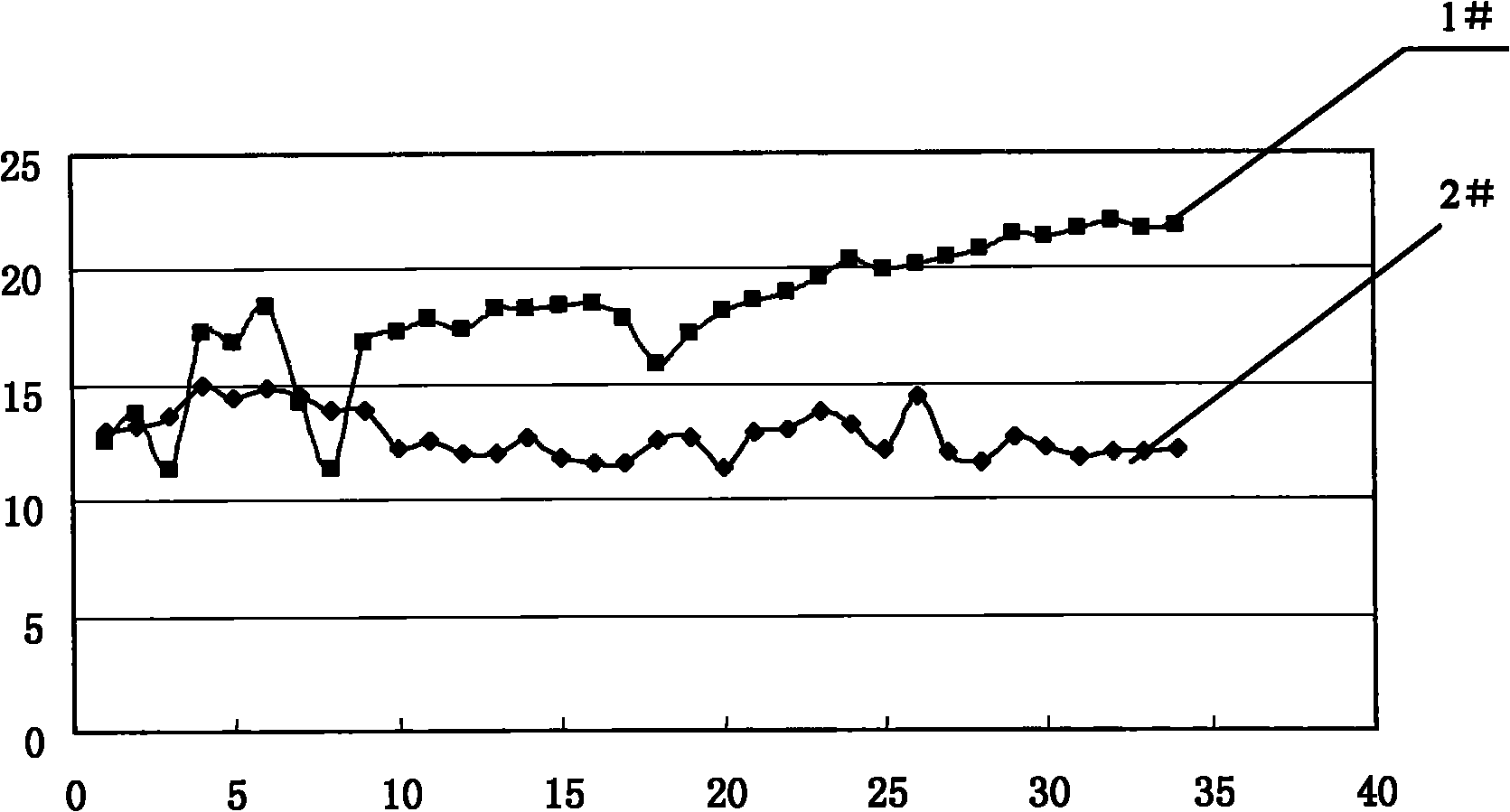

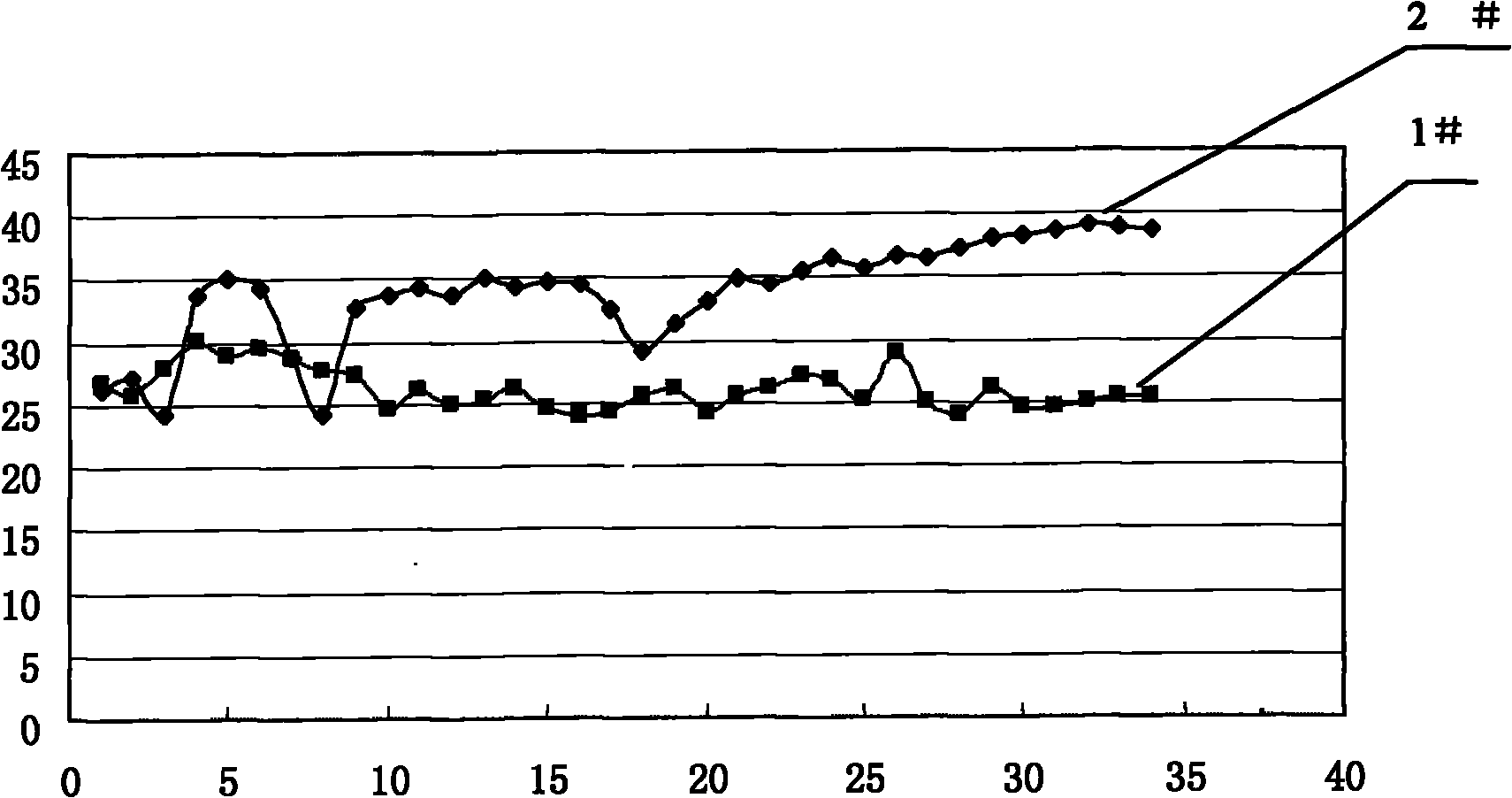

[0046] In the 2# system primary ball mill of a mineral processing workshop in a certain factory, the industrial test of adding grinding media using mixed steel balls was carried out. Under the condition that the added quantity was consistent with the current pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com