Method for preparing nanometer Pd electrocatalyst

An electrocatalyst and nanotechnology, applied in the field of electrocatalyst preparation, can solve the problems of difficult control of reaction conditions, difficult industrial production, uneven products, etc., achieve controllable shape and size, realize shape and size regulation, overcome Instruments and equipment require higher effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: Preparation of nano-Pd electrocatalyst for 8h reaction in dark conditions

[0044] 1. Preparation of hexagonal lyotropic liquid crystals

[0045] Weigh 2.4013g sodium lauryl sulfate, 0.0374g NaCl, 0.103g PdCl 2 Mix with 6mL of water, heat up to 35°C under airtight conditions to dissolve, then add 8.88mL of cyclohexane dropwise under stirring, and then add 1.29mL of n-pentanol dropwise under stirring to obtain a stable gel, namely component A;

[0046] 2. Reduction of Pd salt precursor

[0047] Put component A in a dark box to react for 8 hours, and the yellow-brown stable gel reacts to dark brown to obtain component B;

[0048] 3. Post-processing

[0049] Add 10mL of isopropanol to component B to obtain a black suspension, ultrasonically disperse for 7min, centrifuge and wash for 30min, wash repeatedly 3 times, add 8mL of ethanol and disperse evenly, then put it in a vacuum oven at 40°C for 24h to obtain nano Pd electrocatalyst.

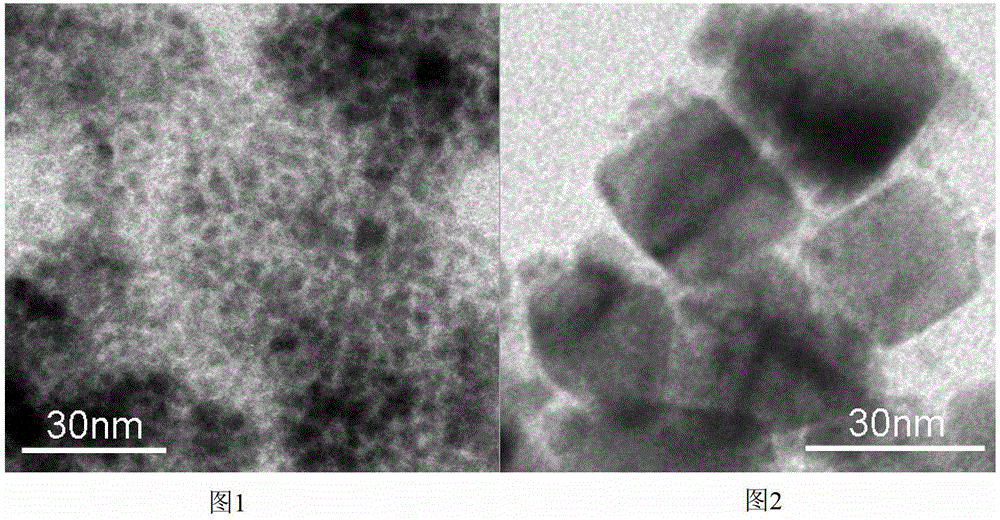

[0050] The microscop...

Embodiment 2

[0051] Embodiment 2: Preparation of nano-Pd electrocatalyst for 72h reaction under dark conditions

[0052] The preparation method of this example is the same as that of Example 1, except that in step 2, component A was reacted in a dark box for 72 hours to obtain component B.

[0053] The microscopic morphology of the nano-Pd electrocatalyst prepared in this example is as follows: figure 2 As shown, the particles have regular shapes such as quadrilaterals, pentagons, and decahedrons, and the particle size is 30-35nm. Compared with the microscopic shape and size of nano-Pd prepared by reacting for 8 hours, the regularity of the particles is significantly improved, and the size of the particles is also large. Significantly increased, indicating that with the extension of the reaction time, the morphology and size of nano-Pd can be regulated. The electrocatalytic activity of nano-Pd electrocatalysts for formaldehyde oxidation is as follows: Figure 6 As shown in (b), in the p...

Embodiment 3

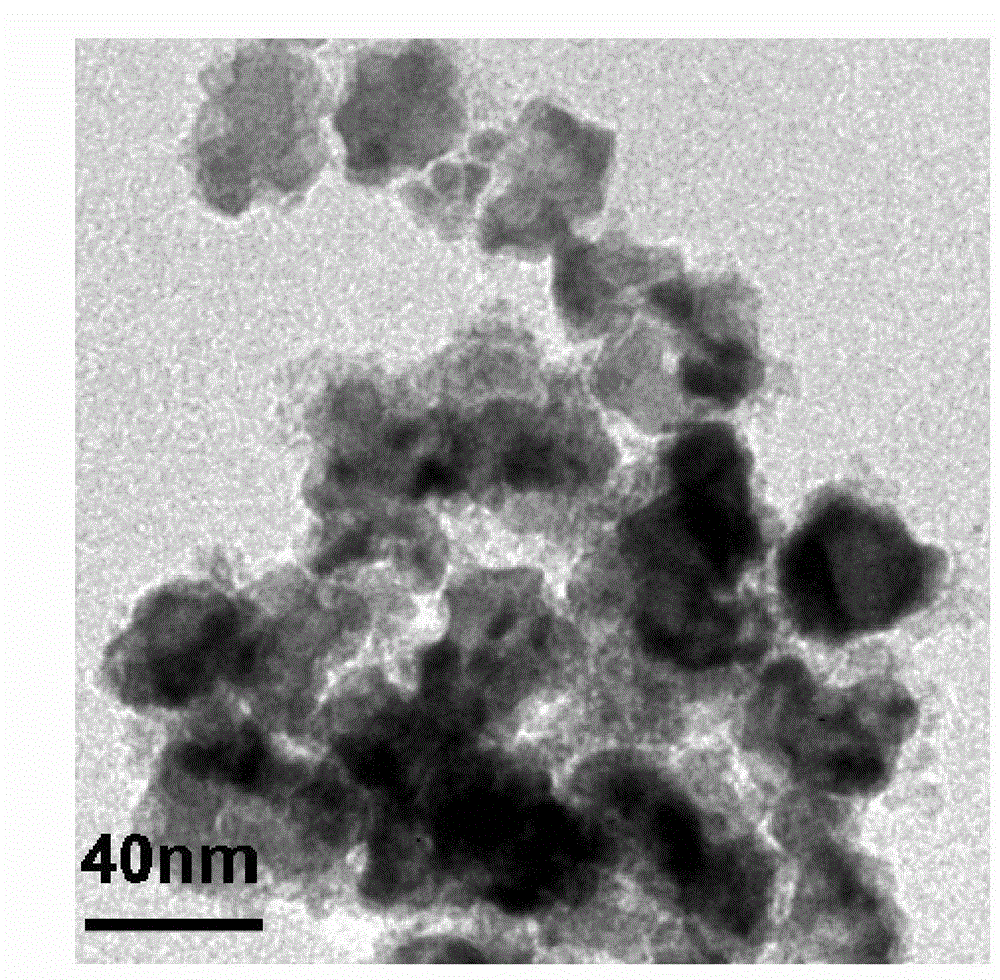

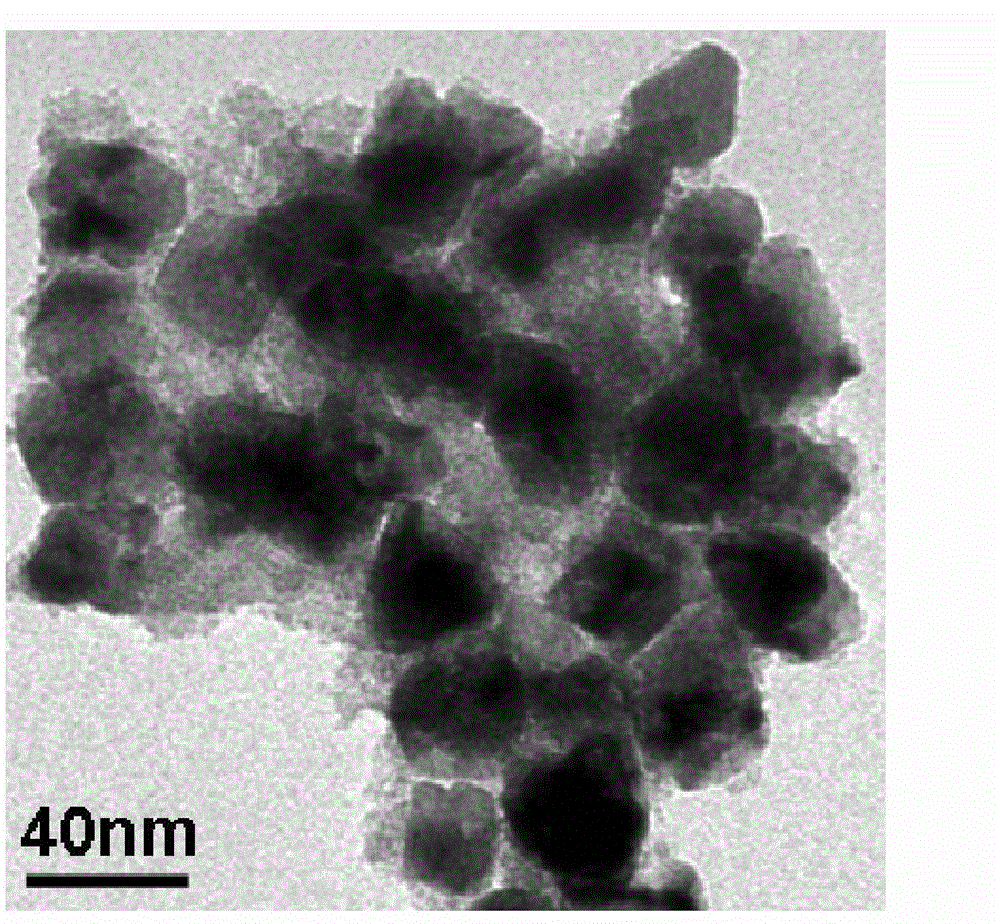

[0054] Embodiment 3: the preparation of 40W incandescent lamp radiation 24h nanometer Pd electrocatalyst

[0055] 1. Preparation of hexagonal lyotropic liquid crystals

[0056] Weigh 0.8g sodium dodecyl sulfate (SDS), 0.012gNaCl, 0.01gPdCl 2 and 2mL of water in a reaction vessel, sealed and dissolved in a water bath at 35°C to obtain a yellow-brown viscous liquid, add 3mL of cyclohexane dropwise under magnetic stirring to obtain a yellow-brown unstable emulsion, and then add dropwise 0.43mL n-amyl alcohol, to obtain a translucent tan stable gel, component A;

[0057] 2. Reduction of Pd salt precursor

[0058] Put component A in a self-made light box, and use an incandescent lamp to irradiate and react for 24 hours. The wattage of the incandescent lamp is 40W. The yellow-brown stable gel reacts to dark brown, and component C is obtained;

[0059] 3. Post-processing

[0060] Add 10mL of isopropanol to component C to obtain a black suspension, ultrasonically disperse for 7min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com