Method for removing silicon and phosphorus impurities from rich-vanadium desorption liquid

A technology of desorption liquid and silicon phosphorus, which is applied in the direction of improving process efficiency, can solve the problems of excessive pH value adjustment, affecting product quality, and large solution processing volume, so as to reduce the amount of addition, reduce the burden of washing, and improve the process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

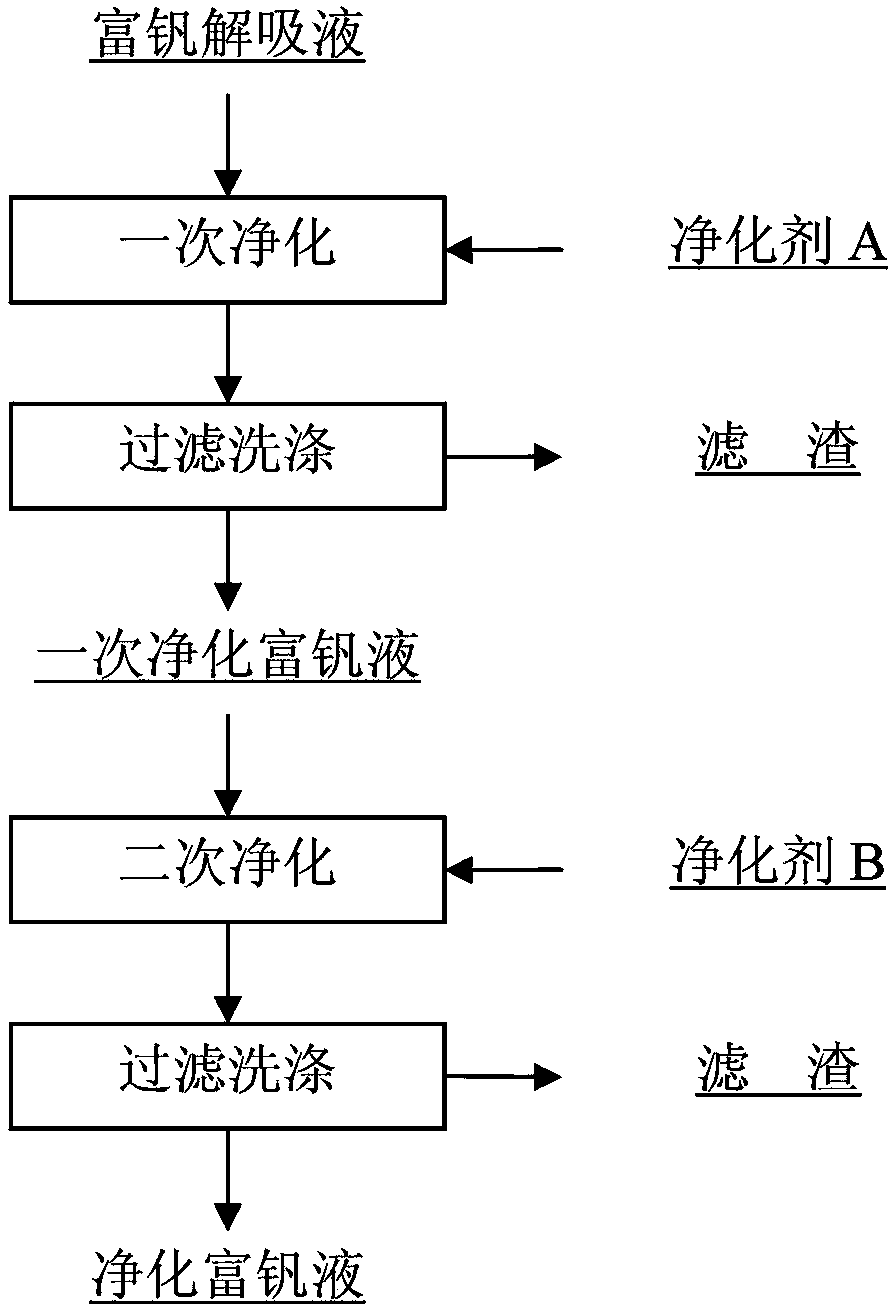

[0026] a kind of like figure 1 Shown the method for removing silicon phosphorus impurity from rich vanadium desorption liquid of the present invention, the rich vanadium desorption liquid to be treated is the rich vanadium high silicon phosphorus desorption liquid that desorbs from anion adsorption resin, wherein contains [V 2 o 5 ]62.37g / L, [P]12.29g / L and [SiO 2 ] 5.66g / L, pH is 5.2. The method specifically includes the following steps:

[0027] (1) Add 3L of the above-mentioned vanadium-rich desorption solution into a 5L mixing tank, and adjust the temperature of the vanadium-rich desorption solution to about 50°C;

[0028] (2) Add 250ml of lime emulsion (containing Ca(OH) 2 about 150g, which is about 0.85 times the required theoretical amount), after stirring, let it fully react at room temperature for 2 hours, vacuum filter the resulting reaction solution, rinse with 500ml of water, and obtain 415g of wet residue, and obtain a purified vanadium-enriched solution 3475...

Embodiment 2

[0033] a kind of like figure 1 Shown the method for removing silicon phosphorus impurity from rich vanadium desorption liquid of the present invention, the rich vanadium desorption liquid to be treated is the rich vanadium high silicon phosphorus desorption liquid that desorbs from anion adsorption resin, wherein contains [V 2 o 5 ]62.37g / L, [P]12.29g / L and [SiO 2 ] 5.66g / L, pH is 5.2. The method specifically includes the following steps:

[0034] (1) Add 60L of the above-mentioned vanadium-rich desorption solution into a 100L mixing tank, and adjust the temperature of the vanadium-rich desorption solution to about 30°C;

[0035] (2) Add 5L of lime emulsion (containing Ca(OH) 2 about 3.0kg, which is about 0.85 times the required theoretical amount), after stirring, let it fully react at room temperature for 2 hours, vacuum filter the resulting reaction solution, rinse with 10L of water, and obtain 8.25kg of wet residue, which is a purified rich Vanadium liquid 69.5L, whic...

Embodiment 3

[0040] a kind of like figure 1 Shown the method for removing silicon phosphorus impurity from rich vanadium desorption liquid of the present invention, the rich vanadium desorption liquid to be treated is the rich vanadium high silicon phosphorus desorption liquid that desorbs from anion adsorption resin, wherein contains [V 2 o 5 ]62.37g / L, [P]12.29g / L and [SiO 2 ] 5.66g / L, pH is 5.2. The method specifically includes the following steps:

[0041] (1) at 23m 3 Add 15.0m of the above vanadium-rich desorption solution into the stirring tank 3 , the temperature of the vanadium-rich desorption solution is 20°C;

[0042] (2) Add 1.2 m of lime emulsion 3 (with Ca(OH) 2 about 750kg, which is about 0.85 times of the required theoretical amount), after stirring, it is fully reacted at room temperature for 3 hours, and the resulting reaction solution is vacuum filtered, and the 3 After rinsing with clean water, 2050kg of wet slag was obtained, and 17.5 m of vanadium-enriched liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com