High-thermal-conductivity carbon fiber composite material and preparation method thereof

A technology of carbon fiber and composite materials, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of increasing the thermal resistance of fibers and heat-conducting particles, and the improvement of thermal conductivity is not significant, so as to achieve synergistic improvement of thermal conductivity, Reduce phonon scattering and interface thermal resistance, low process equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this embodiment, the specific preparation parameters of the carbon fiber skeleton with a three-dimensional oriented interconnected network structure are:

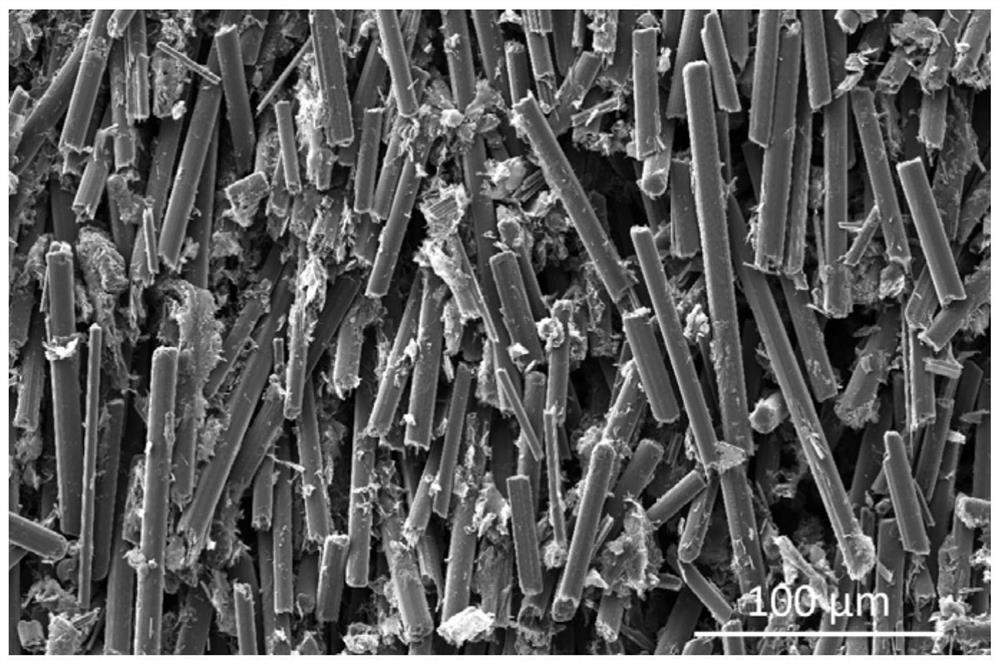

[0034] Chopped mesophase pitch-based carbon fiber (MPCF) was selected as carbon fiber, with a diameter of 10 μm and a length distribution between 100 and 200 μm; graphene oxide was exfoliated by electrochemical method, and its sheet diameter was concentrated at 1.5 μm. The thickness is 1 nm.

[0035] (1) Take the graphene oxide exfoliated by the electrochemical method, prepare 20 mL of graphene oxide / water dispersion with a concentration of 10 mg / mL, and ultrasonically 30 min to make it completely dispersed. Weigh 6.8 g of chopped mesophase pitch-based carbon fibers and add them to the aqueous dispersion of graphene oxide, disperse with magnetic stirring for 1 hour, ultrasonically disperse for 30 minutes, and then disperse with magnetic stirring for 1 hour, so that the carbon fibers and graphene oxide are fully mi...

Embodiment 2

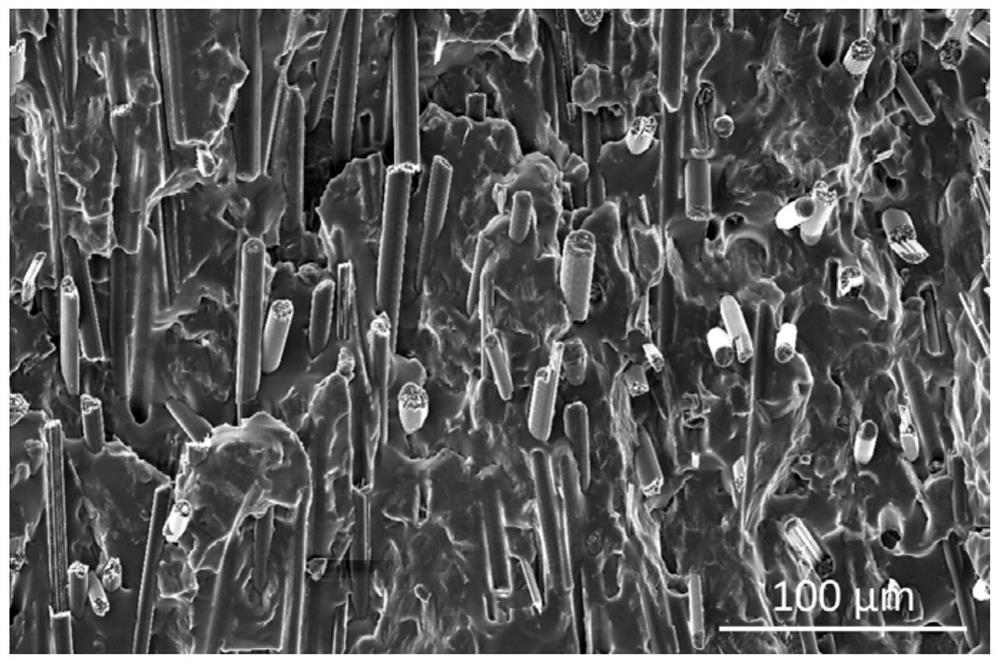

[0040] In this embodiment, the specific preparation parameters of the carbon nanotube fiber skeleton with a three-dimensional oriented interconnected network structure are:

[0041] Electrospun carbon nanotube fibers that have been cut off are selected, and their diameters are concentrated at 9 μm, and their lengths are distributed between 400 and 650 μm. 1nm.

[0042] (1) Take the graphene oxide exfoliated by the electrochemical method, prepare 20 mL of graphene oxide / water dispersion with a concentration of 5 mg / mL, and disperse it completely and evenly by ultrasonication for 30 min. Weigh 5.7g of carbon nanotube fibers into the graphene oxide water dispersion, magnetically stir and disperse for 1h, ultrasonically disperse for 30min, then magnetically stir and disperse for 1h, so that the carbon nanotube fibers and graphene oxide are fully mixed and dispersed evenly .

[0043] (2) Transfer the carbon nanotube fiber / graphene oxide mixture to a hydrothermal reaction kettle, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com