Method for treating vanadium extracting industrial acid wastewater and comprehensively recycling valuable metal

A technology for acidic wastewater and valuable metals, applied in cement production, improvement of process efficiency, calcium/strontium/barium sulfate and other directions, can solve the problem of generating a large amount of slag as mixed slag, affecting the quality of vanadium-enriched products, affecting the Process operation and other problems, to achieve the effects of easy filtration, reduced addition and processing costs, and low requirements for process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

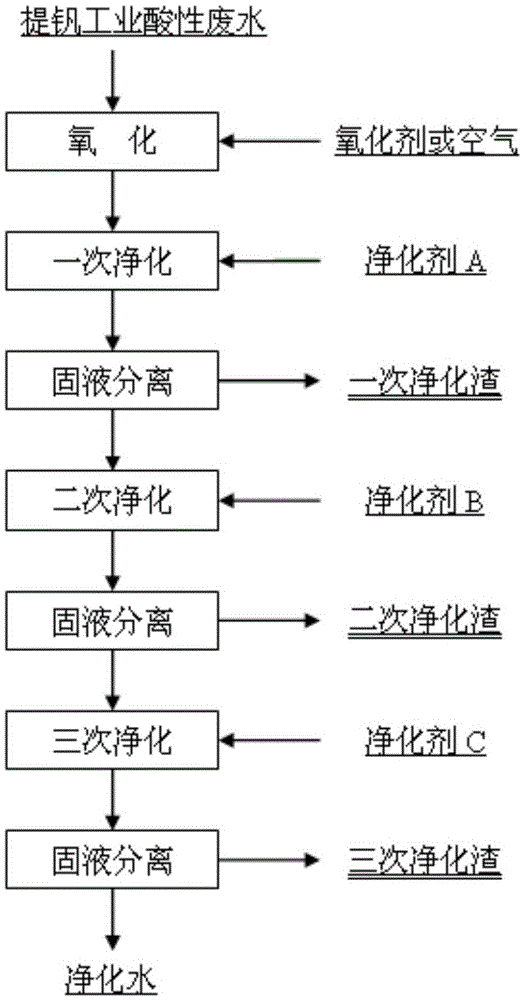

Method used

Image

Examples

Embodiment 1

[0034] A method for the treatment of acidic wastewater in the vanadium extraction industry and the comprehensive recovery of valuable metals. The acidic wastewater to be treated is the sulfuric acid leaching solution that is absorbed and enriched in vanadium by an anion adsorption resin. It contains [V 2 o 5 ]0.05g / L, [P]0.29g / L, [SiO 2 ]0.16g / L, [Fe 3+ ]1.55g / L, [Fe 2+ ]0.009g / L, [Al 3+ ]4.16g / L, [Zn 2+ ]2.16g / L, [Cu 2+ ]0.15g / L, [Cr 3+ ]0.19g / L, [Ni 2+ ]0.095g / L, [Co 2+ ]0.025g / L, [Cd 2+ ] 0.085g / L, pH is 1.8. The method specifically includes the following steps:

[0035] (1) Add 3L of the above-mentioned acidic waste liquid into a 5L mixing tank, which has been oxidized before ion adsorption, and contains Fe 2+ Very low, no need to oxidize.

[0036] (2) Stir and slowly add limestone powder (-200 mesh), control the reaction pH=4.8, make it fully react at room temperature for 2 hours, consume 86.5g of limestone powder, vacuum filter the resulting reaction solution...

Embodiment 2

[0040] A method for the treatment of acidic wastewater in the vanadium extraction industry and the comprehensive recovery of valuable metals. The acidic wastewater to be treated is the raffinate obtained by extracting and enriching vanadium from the sulfuric acid leaching solution, which contains [V 2 o 5 ]0.05g / L, [P]0.29g / L, [SiO 2 ]0.16g / L, [Fe 3+ ]0.005g / L, [Fe 2+ ]4.19g / L, [Al 3+ ]4.16g / L, [Zn 2+ ]2.16g / L, [Cu 2+ ]0.15g / L, [Cr 3+ ]0.19g / L, [Ni 2+ ]0.095g / L, [Co 2+ ]0.025g / L, [Cd 2+ ] 0.085g / L, pH is 2.0. The method specifically includes the following steps:

[0041] (1) Add 3L of the above-mentioned acidic waste liquid into a 5L mixing tank. Due to the reduction before extraction, it contains Fe 2+ The concentration is higher, and the drum air aeration is used for oxidation for 6 hours.

[0042] (2) Stir while blowing in air, slowly add limestone powder (-200 mesh), control the reaction pH=4.8, make it fully react at room temperature for 4 hours, consume 105.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com