Preparing methods for modified graphene and modified graphene slurry

A graphene and modification technology, applied in the field of materials, can solve problems such as toxicity, limit the application of graphene, unfavorable environment and sustainable development of human beings, achieve simple process, realize large-scale industrial production, and require low process equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

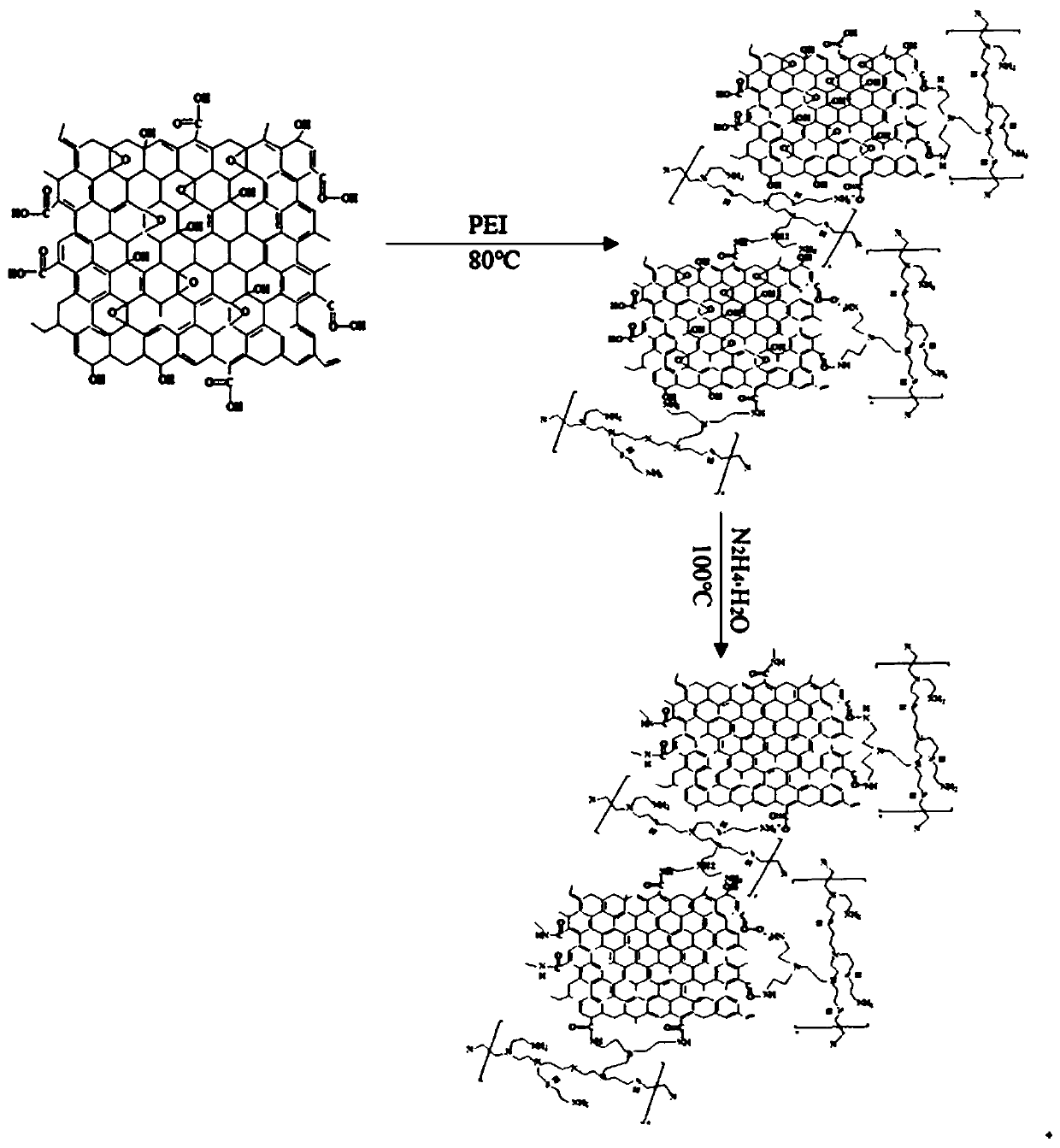

[0022] A preparation method of modified graphene, comprising the following steps:

[0023] (1) Preparation of graphene oxide: graphite powder is oxidized by pre-oxidation and Hummer's method to obtain graphene oxide;

[0024] (2) Evenly disperse graphene oxide in water at a concentration of 5g / L-15g / L, adjust the pH to alkaline, add carboxyl activator at 70-90°C, stir; add branched polyethyleneimine aqueous solution, Reaction; the molecular weight of the branched polyethylenimine is 1000-3000;

[0025] (3) Add an alkaline reducing agent to the reaction solution in step (2), and after the reaction, filter, wash, and dry to obtain modified graphene.

[0026] The present invention uses branched polyethyleneimine, which can increase the steric hindrance between the modified graphene sheet and the sheet, and effectively prevent the agglomeration of the modified graphene due to the van der Waals force, and finally make the prepared modified graphene Graphene has good dispersibilit...

Embodiment 1

[0051] (1) Firstly, graphene oxide was prepared by pre-oxidizing and Hummer's oxidation using 325-mesh natural flake graphite powder.

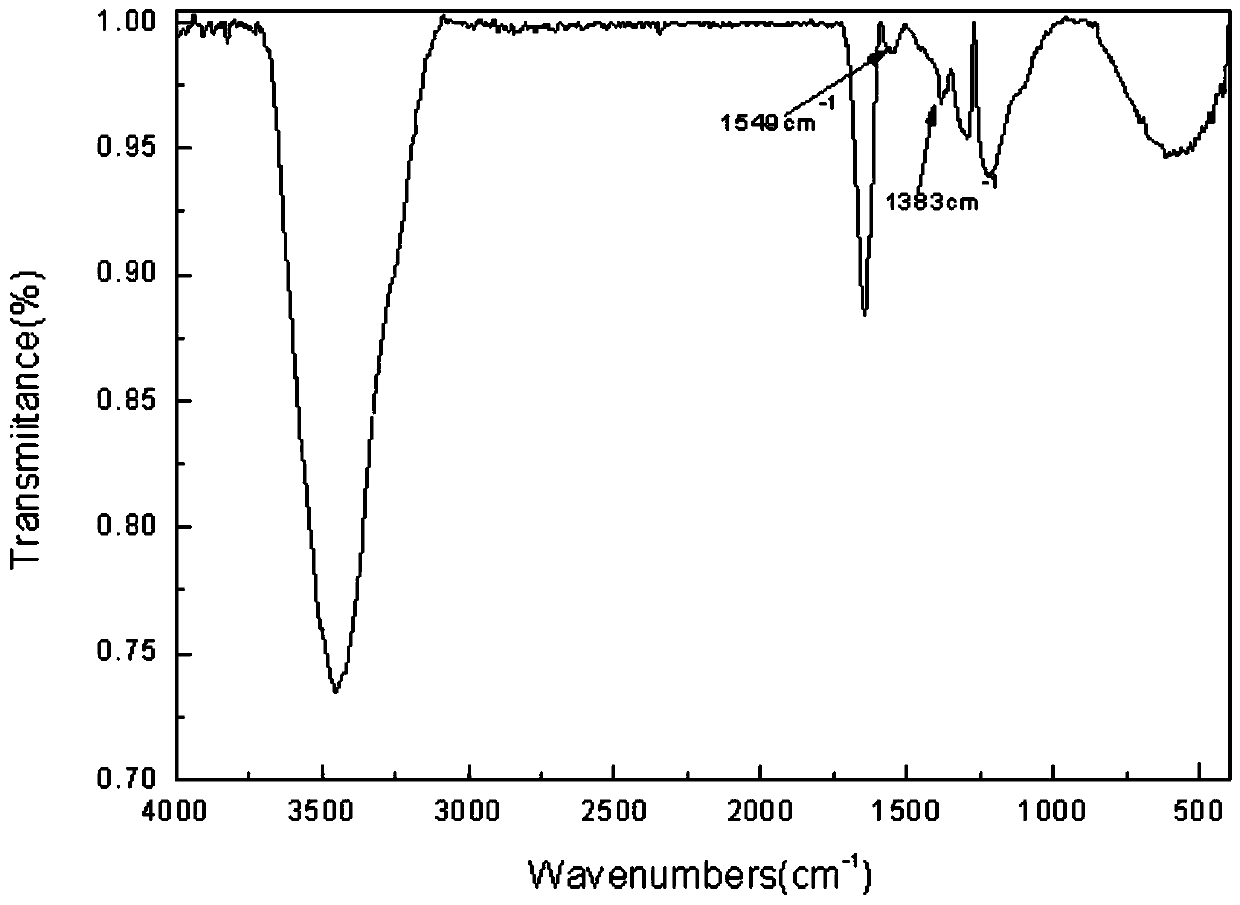

[0052] (2) Take 1 g of the above-mentioned graphite oxide and add it into 100 ml of deionized water, and disperse by ultrasonic for 1 hour to obtain a dispersion liquid with a concentration of 10 g / L. Slowly add 0.1 mol / L NaOH aqueous solution dropwise to adjust the pH of the above dispersion to 8. Then, under the condition of a water bath at 80° C., 50 ml of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide salt solution with a concentration of 10 g / L was added and stirred for 30 min. Finally, 3 g of polyethyleneimine with a molecular weight of 1800 was dissolved in 100 ml of deionized water to prepare a polyethyleneimine solution with a concentration of 30 g / L, added to the above solution, and stirred for 2 hours. At this point, the solution turned from yellow to black.

[0053] (3) The above solution was raised to 100° C., then 20 ml of hydra...

Embodiment 2

[0056] (1) Firstly, graphene oxide was prepared by pre-oxidizing and Hummer's oxidation using 325-mesh natural flake graphite powder.

[0057] (2) Take 1 g of the above-mentioned graphene oxide and add it to 100 ml of deionized water, and disperse it by ultrasonic for 1 hour to obtain a uniform dispersion with a concentration of 10 g / L. Slowly add 0.1 mol / L NaOH aqueous solution dropwise to adjust the pH of the above dispersion to 9. Then, under the condition of a water bath at 70° C., 50 ml of an aqueous dicyclohexylcarbodiimide solution with a concentration of 8 g / L was added and stirred for 30 min. Finally, 3 g of polyethyleneimine with a molecular weight of 1800 was dissolved in 100 ml of deionized water to prepare a polyethyleneimine solution with a concentration of 30 g / L, added to the above solution, and stirred for 2 hours. At this point, the solution turned from yellow to black.

[0058] (3) The above solution was raised to 100° C., then 20 ml of hydrazine hydrate w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com