Method for producing glutinous rice dumplings

A production method and technology of Zongzi, applied in application, food preparation, food science, etc., can solve the problems of shortening cooking time, insufficient and uneven aroma, etc., and achieve the effect of good taste, obvious aroma, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

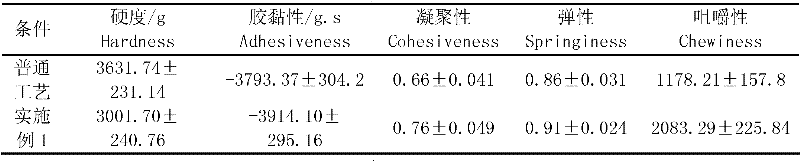

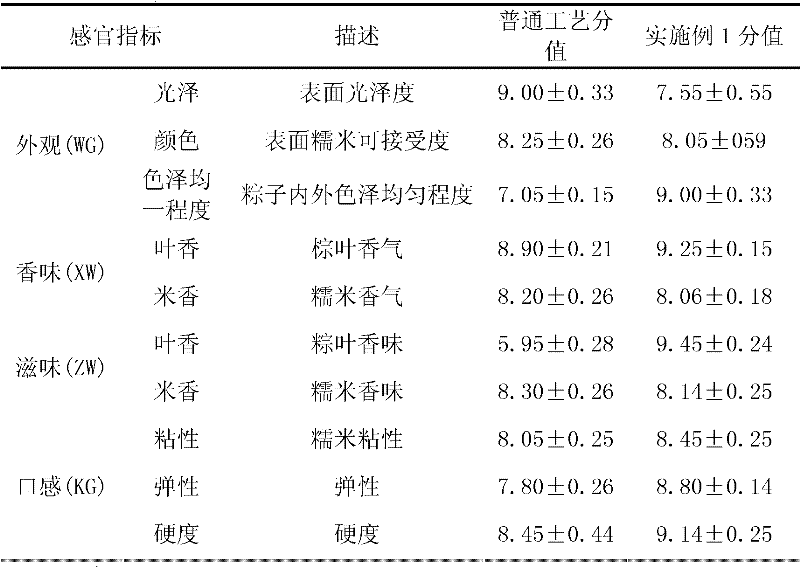

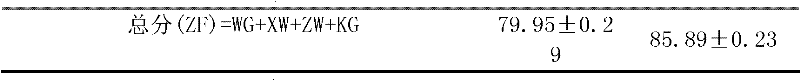

Examples

Embodiment 1

[0018] Carry out according to following production process in the Zongzi production:

[0019] ① Raw material preparation

[0020] a. Clean the rice, wash the glutinous rice and drain the water;

[0021] b. Wash the zong leaves and boil them in boiling water for about half an hour, then soak the cooked zong leaves in clean water;

[0022] ②Preparation of zongzi leaf extract: adopt high-temperature extraction method, the extraction conditions simulate the cooking of zongzi under normal pressure, first crush 20g of dried reed leaves, put them into an extraction container, add 200g of boiling water, and extract in boiling water for 60min, Filter out residue, promptly make the zongzi leaf extract that this technique is used;

[0023] ③Soak glutinous rice: put 100g of glutinous rice into a container, add 200g of Zongye extract, and soak the glutinous rice in Zongye extract for 1 hour;

[0024] ④Ultra-high static pressure treatment: The glutinous rice added with Zongye extract was...

Embodiment 2

[0038] The difference between this embodiment and embodiment 1 is:

[0039] ②Preparation of zongzi leaf extract: use high temperature extraction method, the extraction conditions simulate the cooking of zongzi under normal pressure, first crush 20g of dry reed leaves, put them into the extraction container, add 400g of boiling water, and extract in boiling water for 120min, Filter out residue, promptly make the zongzi leaf extract that this technique is used;

[0040] ③Soak glutinous rice: Put 100g of glutinous rice into a container, add 200g of Zongye extract, and soak the glutinous rice in Zongye extract for 1.5h;

[0041] ④Ultra-high static pressure treatment: the glutinous rice added with Zongye extract is vacuum-packed in a polyethylene plastic bag and placed in an ultra-high pressure device for treatment under a pressure of 200MPa and kept for 30 minutes;

[0042] The texture and organoleptic properties of the prepared zongzi are close to the results of Example 1.

Embodiment 3

[0044] The difference between this embodiment and embodiment 1 is:

[0045] ②Preparation of zongzi leaf extract: adopt high-temperature extraction method, the extraction conditions simulate the cooking of zongzi under normal pressure, first crush 20g of dried lotus leaves, put them into an extraction container, add 300g of boiling water, and extract in boiling water for 90min, Filter out residue, promptly make the zongzi leaf extract that this technique is used;

[0046] ③Soak glutinous rice: Put 100g of glutinous rice into a container, add 200g of Zongye extract, and soak the glutinous rice in Zongye extract for 2 hours;

[0047] ④Ultra-high static pressure treatment: The glutinous rice added with Zongye extract was vacuum-packed in a polyethylene plastic bag and placed in an ultra-high pressure device for treatment under a pressure of 300MPa and kept for 10 minutes;

[0048] The texture and organoleptic properties of the prepared zongzi are close to the results of Example 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com