Preparation method for milk flavor base stock

A milk-flavored and butter-based technology, applied in dough processing, baking, food science, etc., can solve the problems of loss of enzyme activity, decreased inhibitor sensitivity, and high production cost, and achieves strong milk flavor, obvious milk flavor, and high production cost. Pleasant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

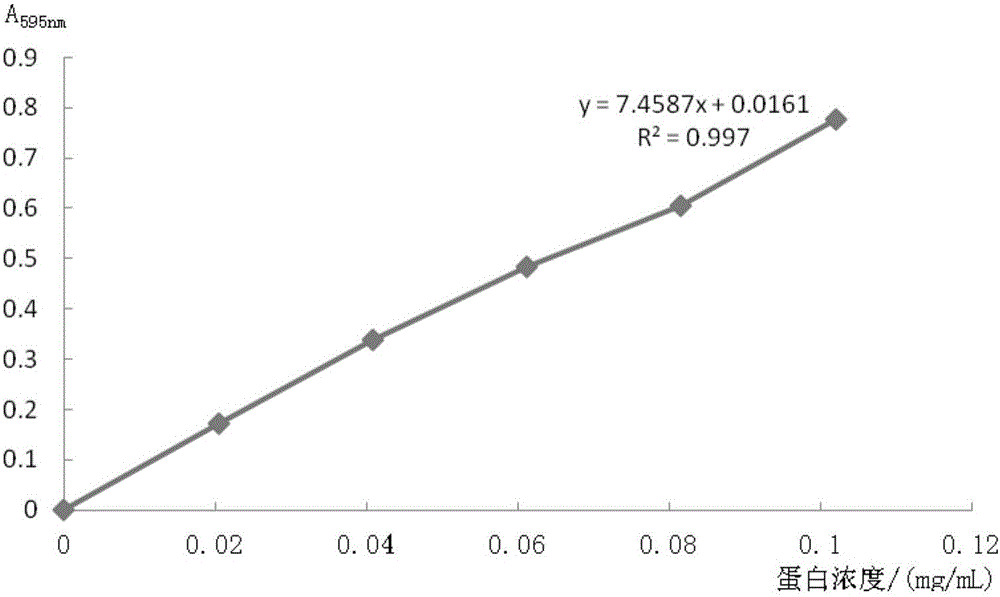

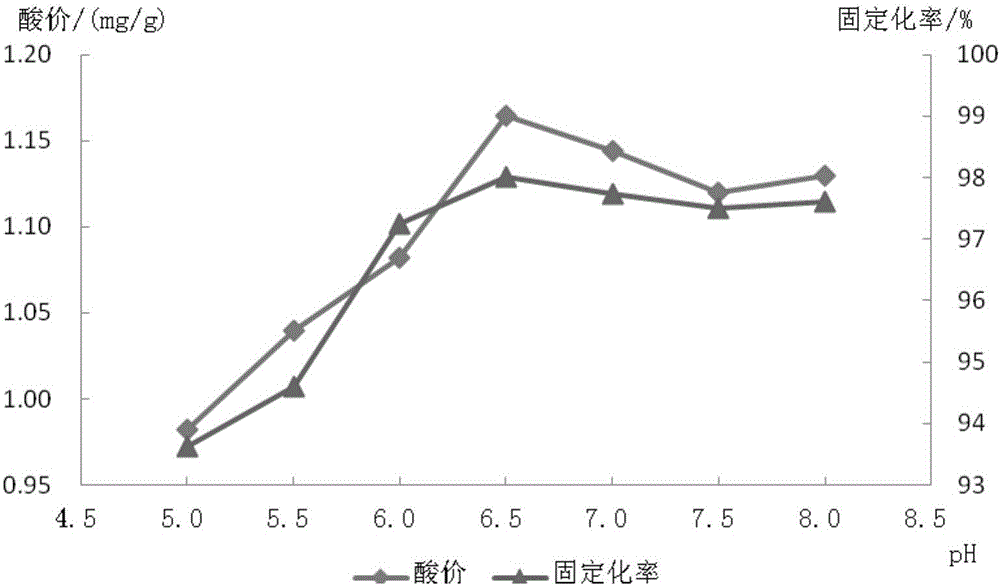

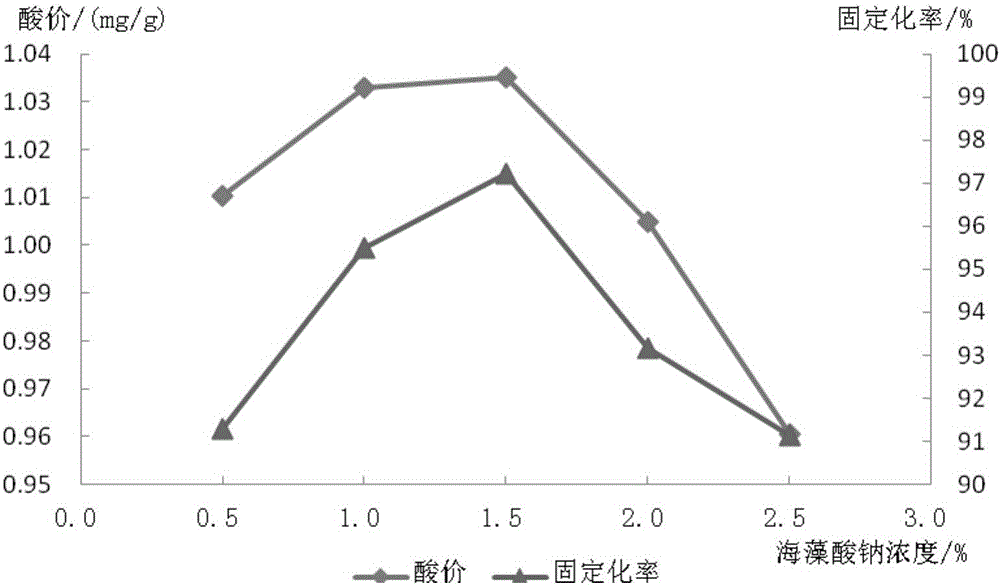

[0060] The present invention uses sodium alginate as a carrier, adopts the embedding method to co-immobilize protease MSD, lipase A6 and lipase MER, and takes the immobilization rate and the enzyme activity of co-immobilized enzymes as the main indicators, and the co-immobilization conditions The optimized co-immobilized enzyme was used to prepare the milk-flavored base material, and the preparation process of the milk-flavored base material was optimized with the acid value and sensory evaluation as the main indicators.

[0061] 1. Materials and methods

[0062] 1.1 Test material

[0063] (1) Butter is commercially available Dome Fresh unsalted butter (lactose 0%, protein 0%, fat 82%).

[0064] (2) Whey powder (lactose 60%, protein 9%, fat 15%) was purchased from Guangzhou Rifeng Animal Husbandry Co., Ltd.

[0065] (3) Lipase A "Amano" 6 (Lipase A "Amano" 6), abbreviated as Lipase A6, was presented by Amano Enzyme Trading (Shanghai) Co., Ltd.

[0066] (4) Lipase MER "Amano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com