Method of producing jam

A technology of jam and strawberry jam, applied in food preparation, application, food science, etc., can solve problems such as inability to prepare, and achieve the effect of good flavor and no green taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

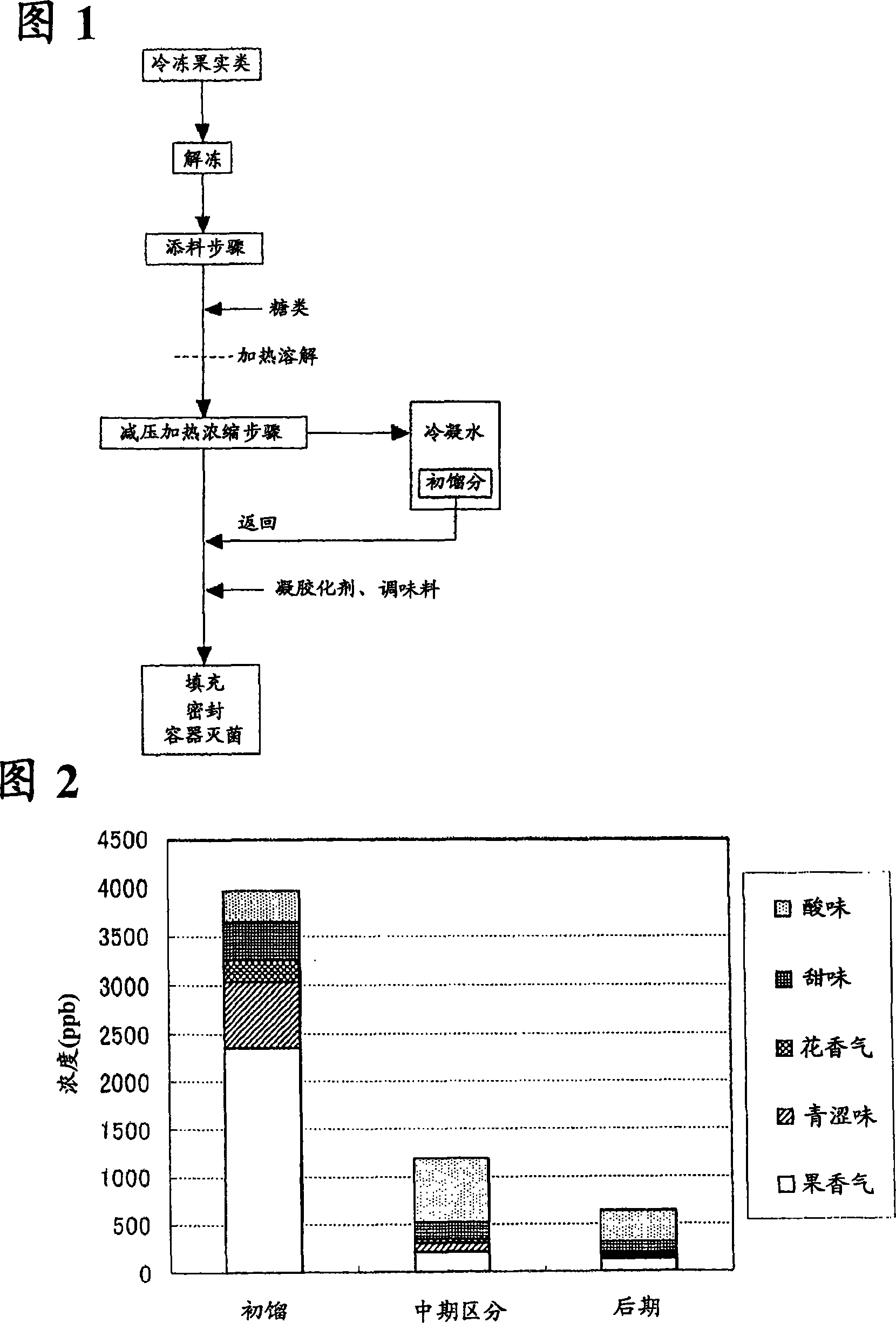

Method used

Image

Examples

Embodiment 1

[0103] Embodiment 1, Comparative Examples 1-11

[0104] Strawberry jam (embodiment 1, comparative example 1, comparative example 2) was prepared according to the method of (1), (2), (3) of above-mentioned test example 1. The return amount of condensed water is 3.8% relative to the feed amount. In Comparative Examples 3-11, the following nine kinds of commercially available strawberry jams were prepared.

Embodiment 2

[0148] Embodiment 2 (figs)

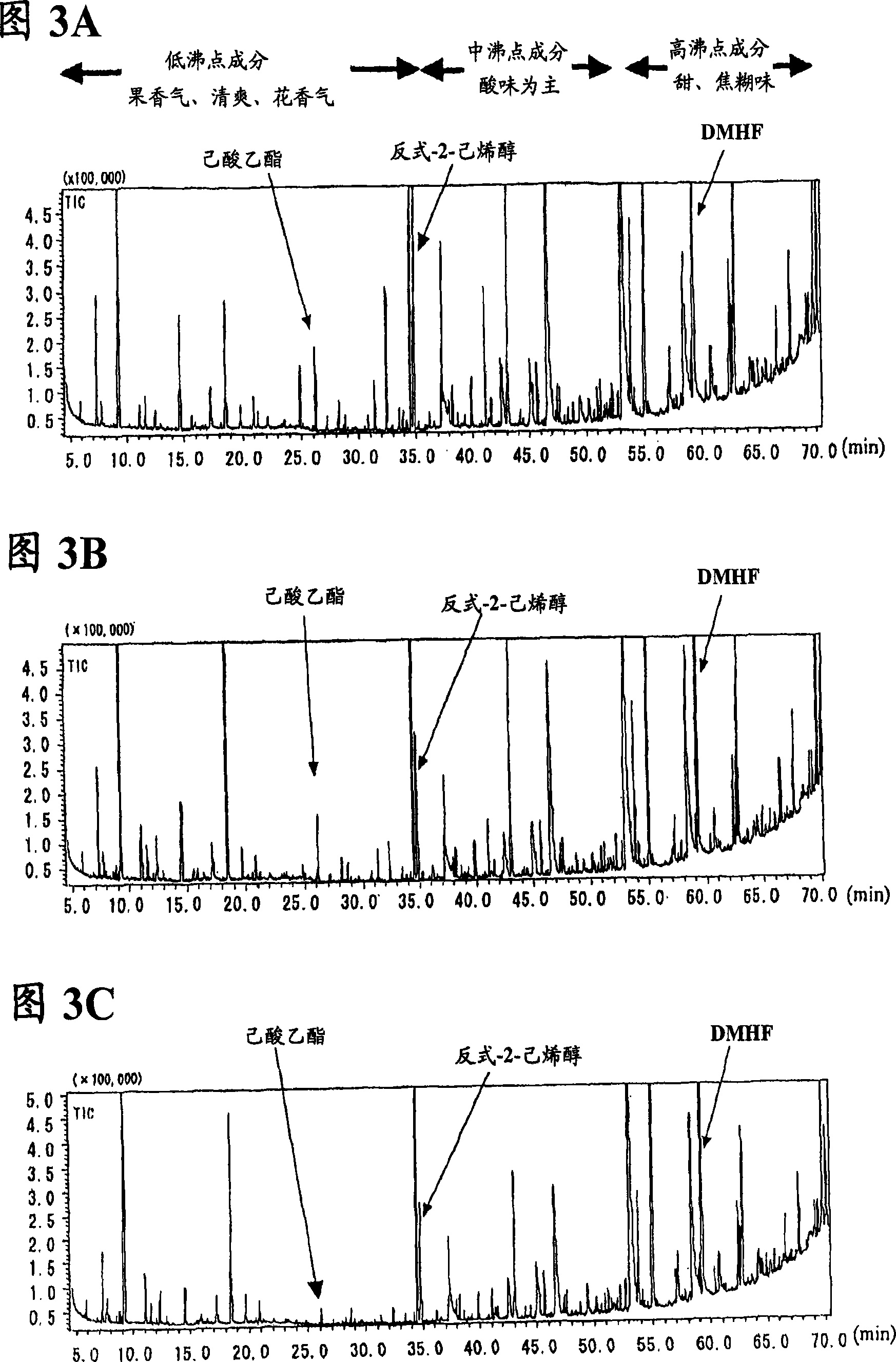

[0149] The fig jam of the proportions in Table 6 was prepared as follows. First, figs and sugar were heated to 40° C. in a container for heating and concentrating under reduced pressure to dissolve the sugar. Next, the absolute pressure of the vacuum kneader was 7.4 kPa, and the product temperature was 40° C. and concentrated under reduced pressure, and 1870 mL (18.3% of the weight of the feed) was distilled off in about 8 minutes for concentration. At this time, the distilled steam is condensed through a multi-tube heat exchanger (refrigerant 1 ° C), and 100 mL (about 1% of the weight of the feed) of condensed water (the temperature when it is just discharged from the heat exchange part) is taken from the initial fraction. : 4°C) into 19 fractions No.1 to No.19.

[0150] Next, add sour (citric acid) aqueous solution and pectin aqueous solution to the concentrate, return 500mL of No.1-No.5 condensed water (4.9% of the weight of the addition) to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com