Anaerobic reaction tank for processing intensive cattle farm excreta

An anaerobic reaction tank and excrement technology, which is applied in the fields of excreting fertilizers, adapting to climate change, and treating biological organic parts, etc. It can solve the problems of inability to realize material turnover and stirring, inability to solve complete fermentation, increase equipment and energy consumption, etc. , to achieve the effect of easy automatic control, good heat and mass transfer effect, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

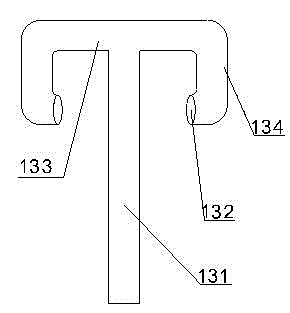

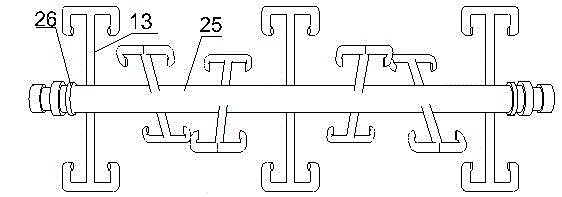

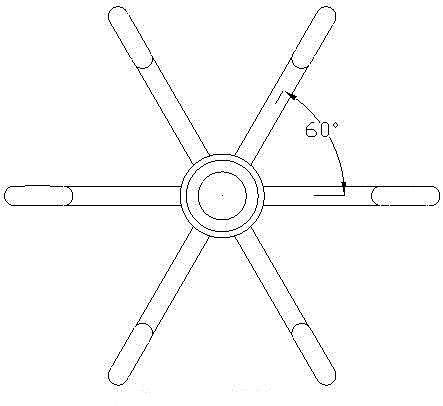

[0032] Such as figure 1 As shown, a kind of anaerobic reaction tank for processing intensive cattle farm excreta, the outer layer of the anaerobic reaction tank 19 is designed with a jacket 9 structure, and the inside of the anaerobic reaction tank is provided with a stirring plate 13, such as figure 2 As shown, the stirring plate 13 is composed of a stirring plate main rod 131, a stirring plate port 132, a stirring plate strut 133 and a stirring plate wing rod 134. The stirring plate main rod 131 is fixed on the rotating shaft 25, and the two ends of the rotating shaft are provided with seals. Ring 26, and connected with the tank body through bearings. The anaerobic reaction tank adopts a horizontal design with a length-to-diameter ratio of 1:3.4. Stirring plate 13 adopts fluororesin as the outer lining, and the thickness of the outer lining is 2 mm. The section of the port 132 of the stirring plate is circular; the distance between the jacket and the body of the anaerobic...

Embodiment 2

[0036] The present embodiment adopts the anaerobic reaction tank of embodiment 1 to process intensive cattle farm excrement, and the size of the anaerobic reaction tank used is as follows:

[0037] The diameter-to-length ratio is: D:H=1:3.4; the geometric dimension of the elliptical head is: h 1 =600mm (surface length); h 0 =40mm (straight edge length); inner surface area of oval head =6.41m 2 ; Ellipse head volume = 1.93m 3 ; The geometric dimension of the cylinder is: H=6391mm (length); the inner surface area of the cylinder is 39.82m 2 ;Cylinder volume 23.86m 3 , labeled as Figure 6 shown.

[0038] In order for the equipment to function properly, routine fixing and piping connections are required, such as Figure 7 As shown, the anaerobic reaction tank 19 of embodiment 1 is fixed between the two left and right bearing supports 16 through the bearing 8, the other end of the bearing 8 is connected with the shaft coupling 7, and the variable speed motor 2 is located...

Embodiment 3

[0053] In order to test the treatment effect of the anaerobic reaction tank designed by the present invention, the treatment equipment and technology of Example 2 are compared with the treatment results of traditional equipment, and the results are improved in product quality, shortened fermentation time, and product in physical chemistry and biology. There are advantages in terms of academic nature:

[0054] 1. Compared with traditional equipment processing, the quality of the product is good or bad

[0055] By screening the obtained ideal fermentation bacteria, comparing and verifying the processing results with traditional equipment, analyzing the changes in the physicochemical and biological properties of metabolites during the fermentation process, and conducting productive comparative tests, the experimental results are shown in Table 1.

[0056] Table 1

[0057]

[0058] The comparison test shows that the total carbon, total nitrogen, carbon-nitrogen ratio, moistur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com