Flame-retardant anti-dripping hot melting adhesive membrane for flexible flat cable (FFC), and preparation method of hot melting adhesive membrane

A hot-melt adhesive film and anti-dropping technology, which is applied in the direction of adhesives, film/sheet adhesives, adhesive types, etc., can solve the problems of molten dripping or molten particles that are prone to dripping, electrical performance, Increased loss of mechanical properties, toxic or corrosive gases and smog, etc., to ensure that it is not easy to dialysis, has good dispersion and mixing compatibility, and ensures thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

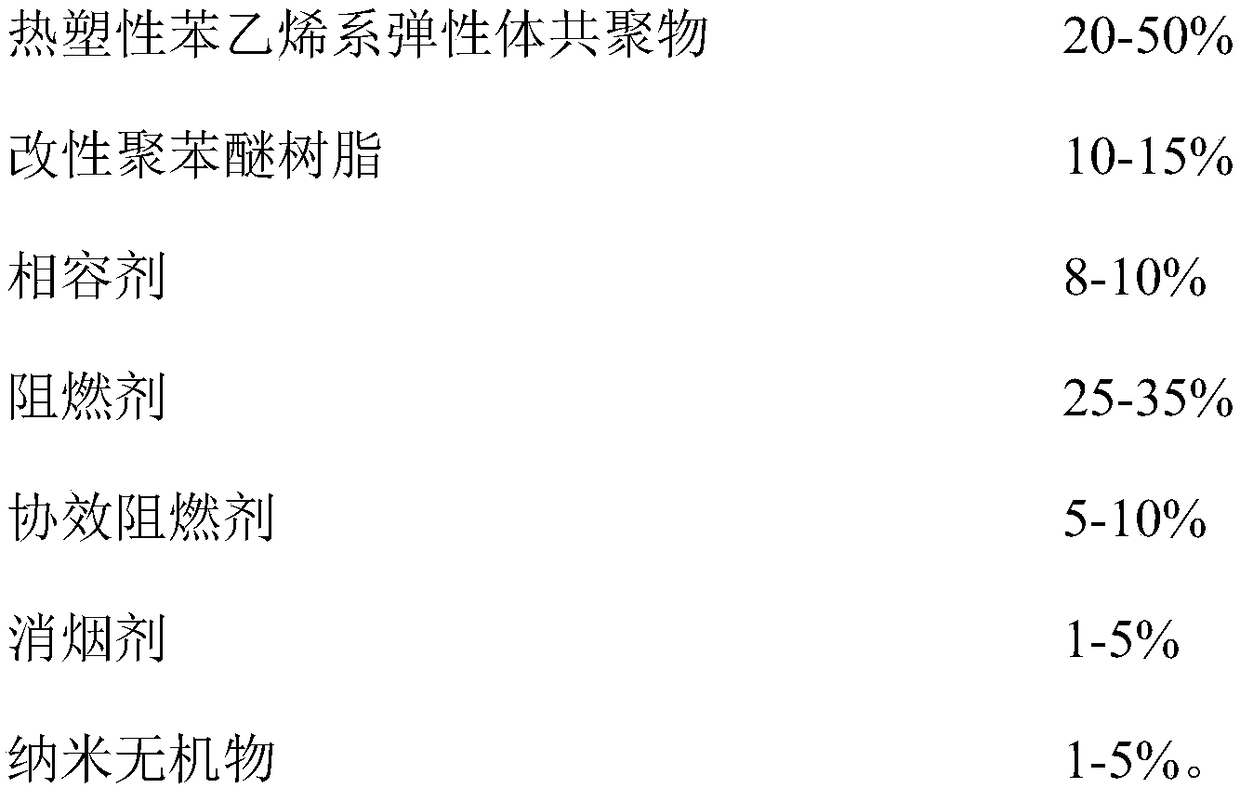

Method used

Image

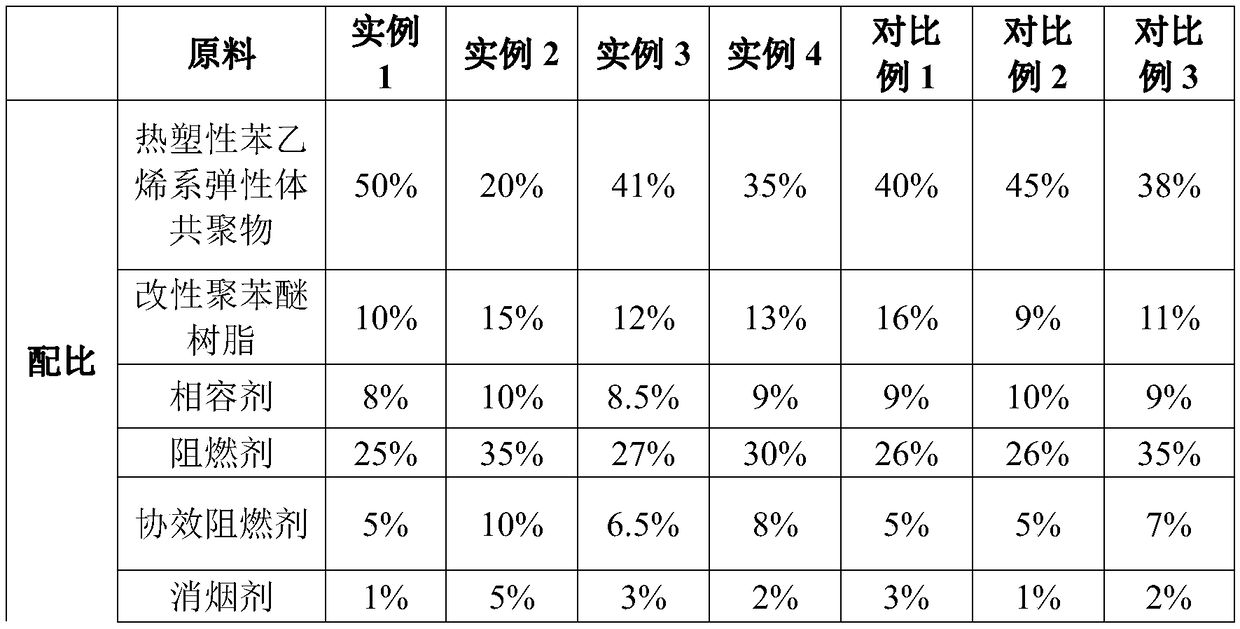

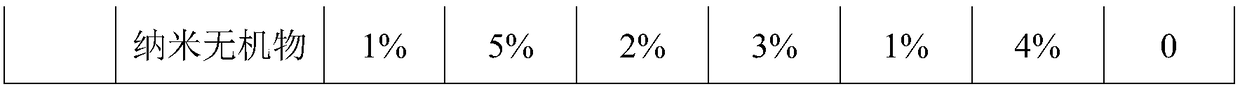

Examples

Embodiment 1

[0034] The test result of embodiment 1 is as follows:

[0035]

[0036]

[0037] It can be seen from the above table that the hot-melt adhesive film for FFC wire obtained in Example 1 can all reach the level of VTM-0 flame retardancy, the afterflame / afterglow does not burn to the 125mm scale, the amount of smoke is low, and the burning particles or droplets Falling objects cannot ignite absorbent cotton balls, and have good flame retardant and anti-droplet performance.

Embodiment 2

[0038] The test result of embodiment 2 is as follows:

[0039]

[0040]It can be seen from the above table that the hot-melt adhesive film for FFC wires obtained in Example 2 can also reach the VTM-0 flame retardant level, the afterflame / afterglow does not burn to the 125mm scale, the amount of smoke is low, and the burning particles or None of the drippings can ignite the absorbent cotton balls, and it has good flame retardant and anti-melting droplet performance.

Embodiment 3

[0041] The test result of embodiment 3 is as follows:

[0042]

[0043]

[0044] It can be seen from the above table that the hot melt adhesive film for FFC wire obtained in Example 3 can also reach the level of VTM-0 flame retardancy, and the afterflame time is 0, that is, it is extinguished immediately after evacuating the flame, and there is no ignition; Afterflame / Ignition does not burn to the 125mm scale, the amount of smoke is low; and it is quickly extinguished in a short period of time. Due to the high temperature of the burning part, it will be heated and melted and dripped, but neither the burning particles nor the dripping can ignite the absorbent cotton The ball has good flame retardant and anti-droplet performance.

[0045] The test result of comparative example 2 is as follows:

[0046]

[0047] It can be seen from the above table that although the hot melt adhesive film for FFC wires obtained in Comparative Example 2 can reach the VTM-0 flame retardant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com