Stirring linkage component and milk preparer

A technology of linkage components and milk dispensing machines, applied in kitchen utensils, home utensils, beverage preparation devices, etc., can solve the problems of insufficient practicability and long preparation time, and achieve improved uniformity, fast preparation of milk powder, excellent uniformity The effect of mixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

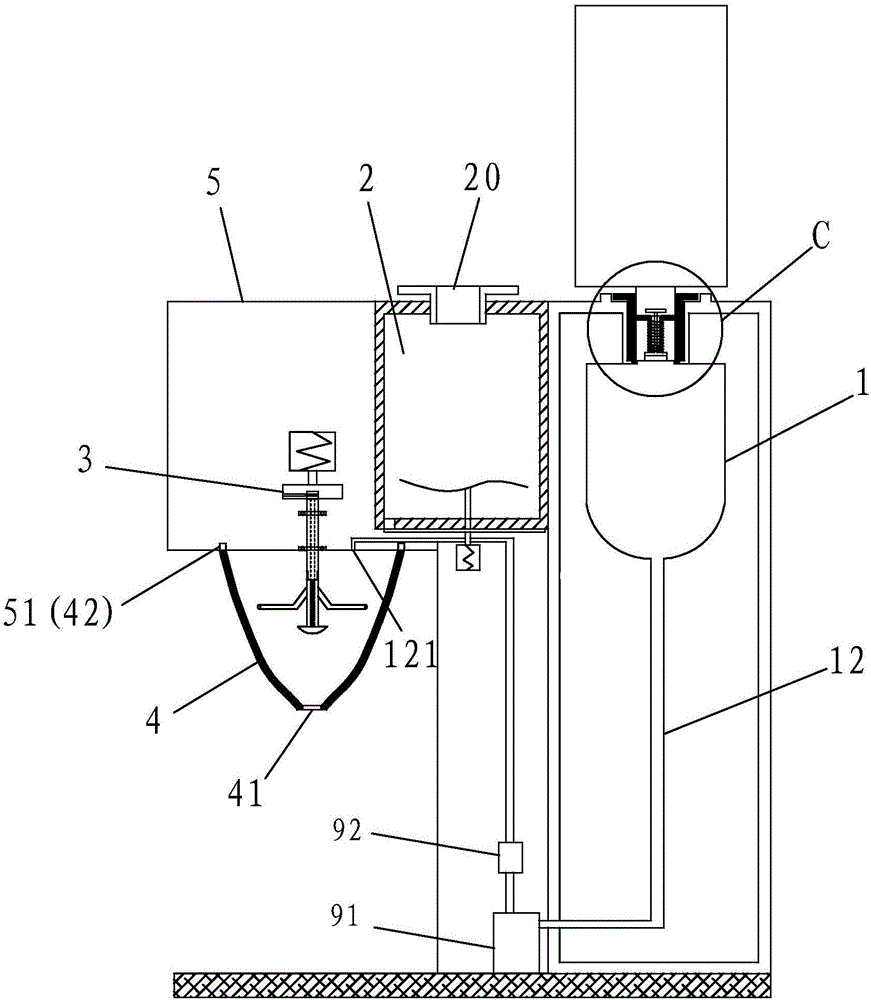

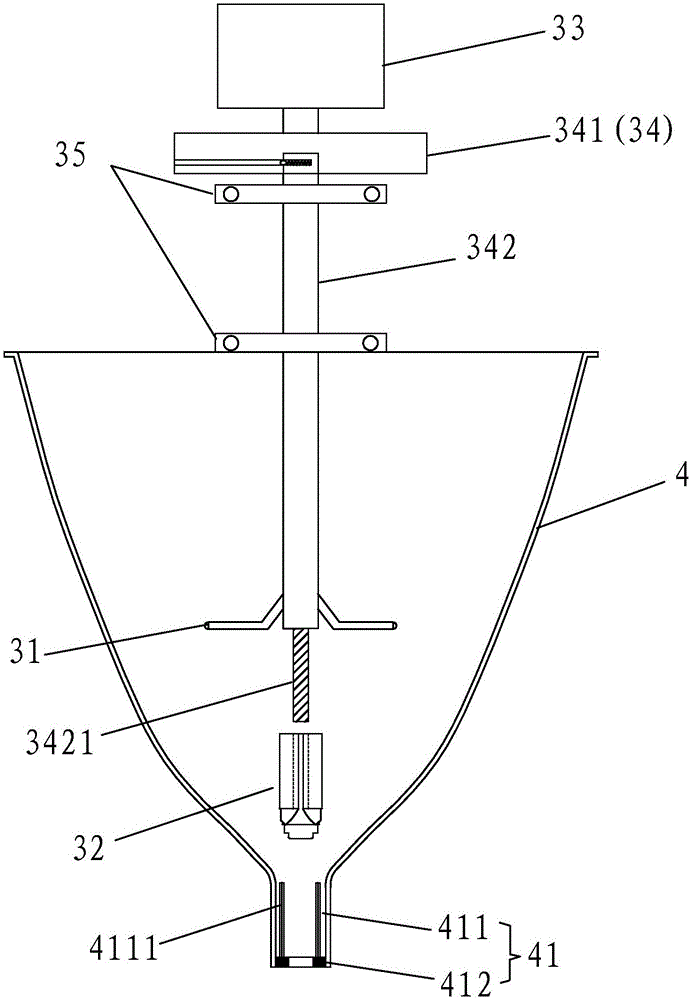

[0061] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

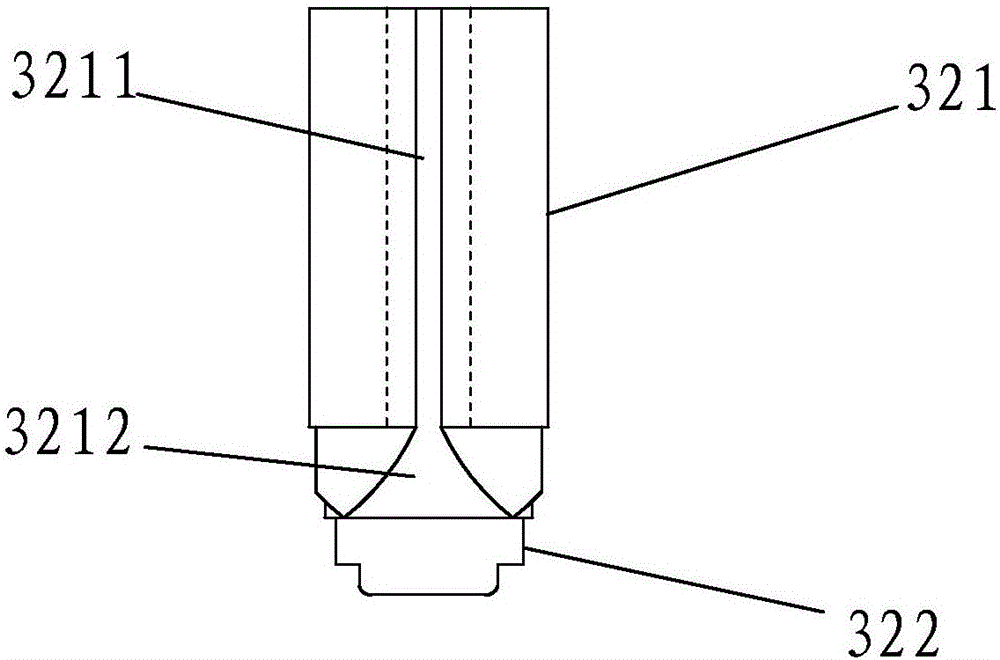

[0062] This case involves a stirring linkage assembly 3, such as Figure 2-5 As shown, it mainly includes a stirring rod 31 , a plug 32 , a driving motor (stepping motor) 33 and a linkage mechanism 34 . The stirring rod 31 and the plug 32 are vertically arranged on the linkage mechanism 34 , and the plug 32 and the stirring rod 31 are connected to the drive motor 33 through the linkage mechanism 34 . The linkage mechanism 34 drives the stirring rod 31 to rotate and stir, and at the same time drives the plug 32 to move, and the plug 32 preferably moves up and down. There are multiple implementations of the linkage mechanism 34 , which will be further elaborated below through two specific implementations.

[0063] For the first embodiment of the linkage mechanism 34, see Figure 2-3 As shown, a coupling 341 and a connecting rod 342 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com