Y-shaped mixer used for sintered powder

A mixing machine and material mixing technology, applied in mixers, mixers with rotating containers, dissolution, etc., can solve the problems of insufficient lateral flow of materials, short mixing time, uneven mixing of materials, etc., to improve the quality of sintered products , Improve mixing efficiency and short mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

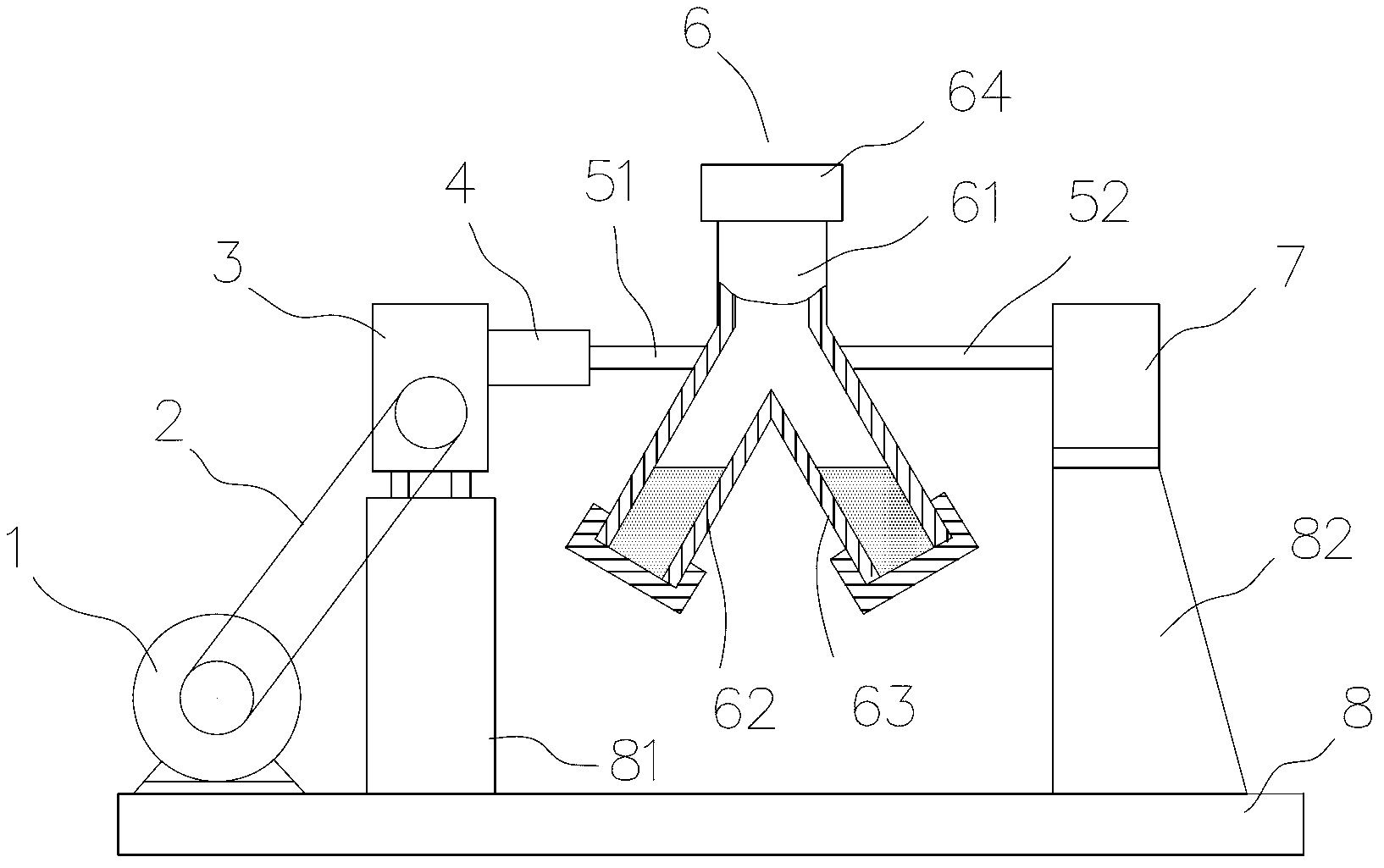

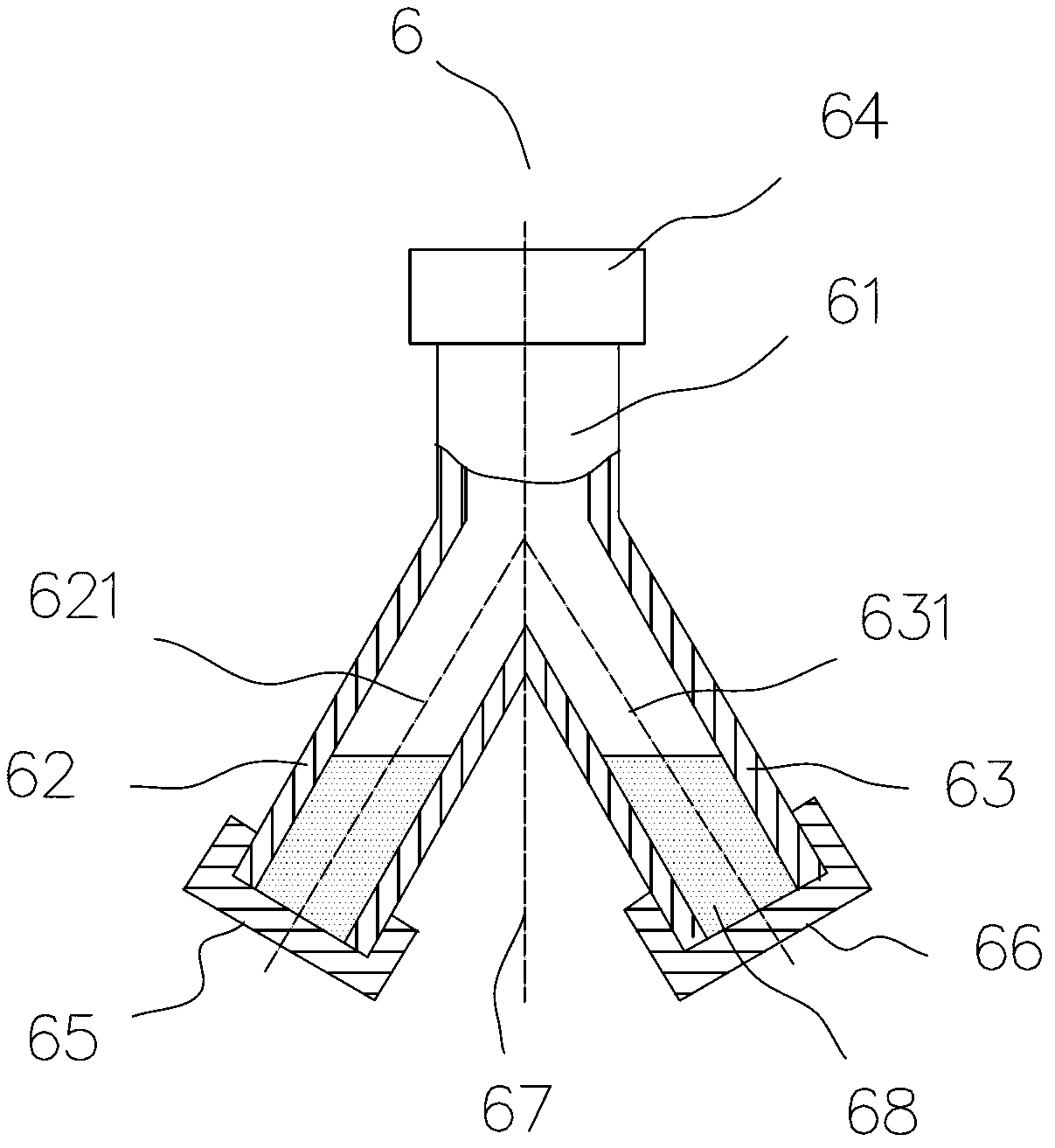

[0012] Y-type mixer for sintering powder of the present invention, such as figure 1 with figure 2 As shown, the mixing container 6 is composed of three Y-shaped cylindrical cylinders 61, 62, and 63. The inner cavities of the three cylinders are the same in diameter, and one of the cylinders arranged perpendicular to the rotating shaft 5 is the main cylinder 61 The other two cylinders are sub-cylinders 62, 63, the two sub-cylinders 62, 63 are symmetrically arranged at the inner end of the main cylinder 61; the included angle between the symmetric centers 621, 631 of the two sub-cylinders 62, 63 It is 30°~50°; the rotating shafts 51, 52 are fixed on both sides of the inner end of the main cylinder 61, and are arranged perpendicular to the center of symmetry 67 of the two sub-cylinders 62, 63; the main cylinder 61 and the two sub-cylinders Covers 64, 65, 66 are respectively provided at the outer ends of 62 and 63. Open any cover to carry out feeding and discharging operations.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com