Reaction still

A technology of reaction kettle and kettle body, applied in the field of reaction kettle, can solve the problems of uneven mixing of materials, uniform mixing degree of materials, affecting product quality, etc., and achieve the effects of improving product quality, uniform mixing of materials, and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

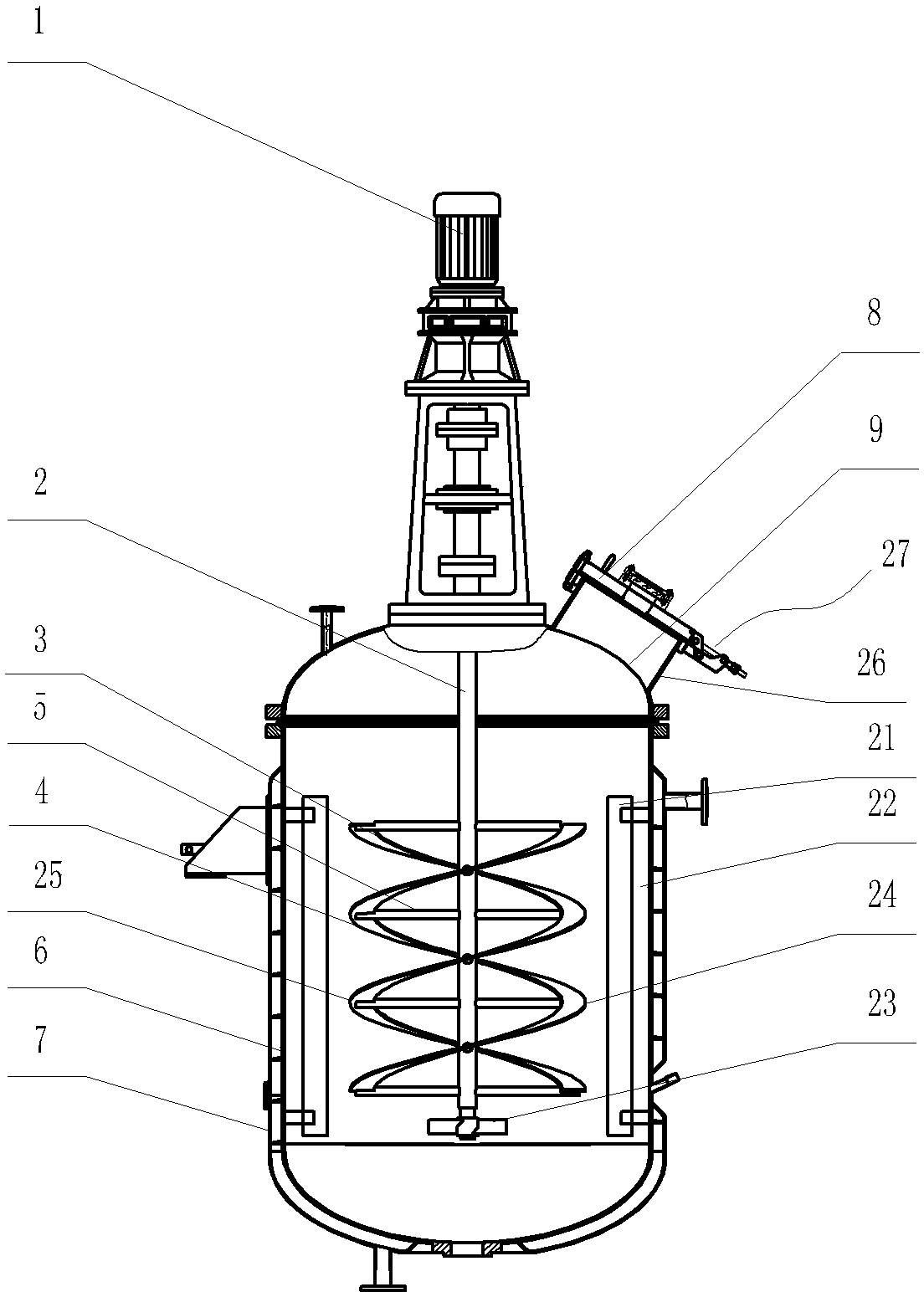

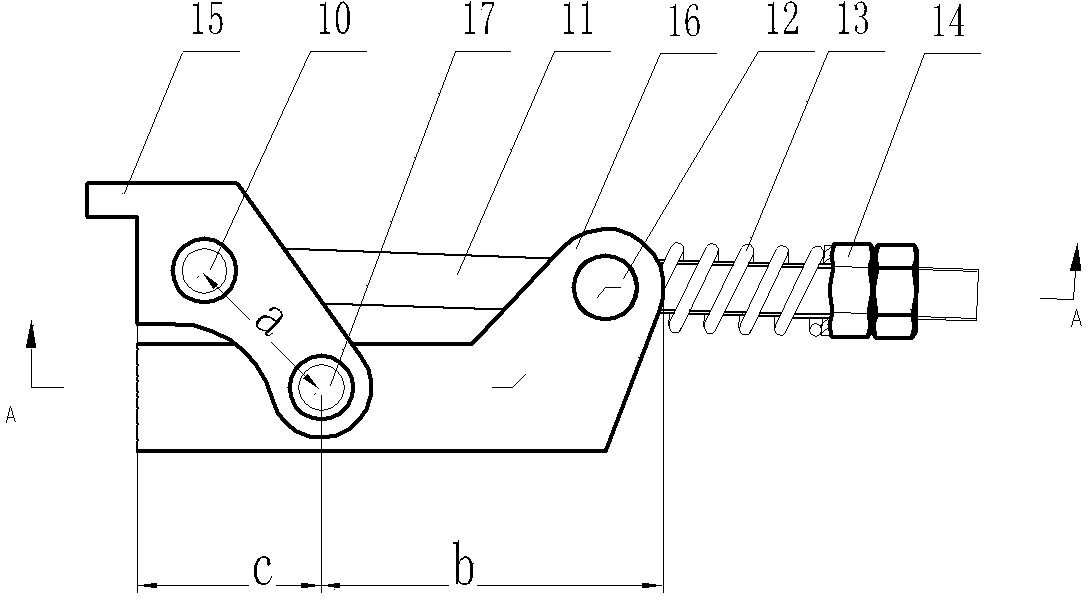

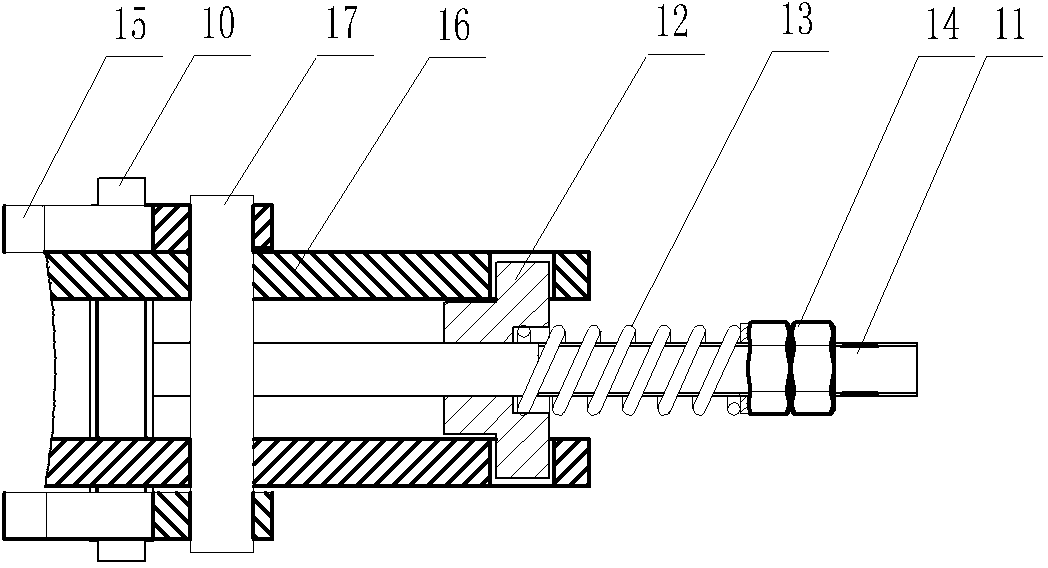

[0017] See Figure 1 to Figure 3 , the reaction kettle, which comprises a kettle body 6, a stirring shaft 2 is arranged in the kettle body 6 and along the axial direction of the kettle body 6, a stirring blade is installed on the stirring shaft 2, and one end of the stirring shaft 2 is connected to the output end of the driving device 1, and the driving device 1 is fixed on the top of the kettle body 6, and is provided with a manhole 9 on the upper part of the kettle body 6, the stirring blade is a spiral ribbon blade, and the spiral ribbon blade is provided with two, and the spiral ribbon blade is symmetrical and spirally arranged on the stirring shaft 2. The blade surface with blades faces the axial direction of the kettle body 6, and the spiral directions of the two helical blades 3 and 4 are opposite; a number of support shafts 5 are fixed on the stirring shaft 2, and the two ends of the support shaft 5 respectively support the same horizontal plane. The helical inflection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com