Method for preparing lithium iron phosphate of anode material of lithium ion battery

A technology for lithium ion batteries and positive electrode materials, which is applied in the field of preparation of lithium iron phosphate, a positive electrode material for lithium ion batteries, can solve the problems of complicated process steps, irregular shapes of products, and difficulty in large-scale production, and achieves reasonable process, The effect of improving the lithium ion diffusion coefficient and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

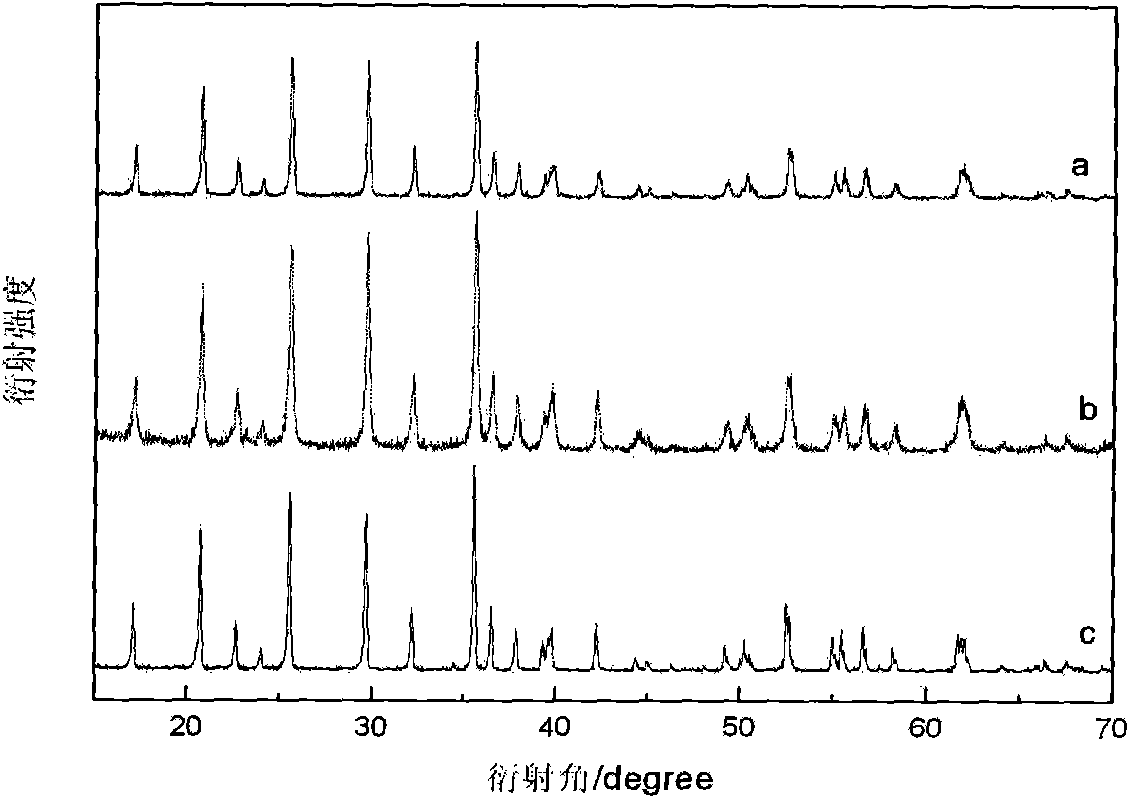

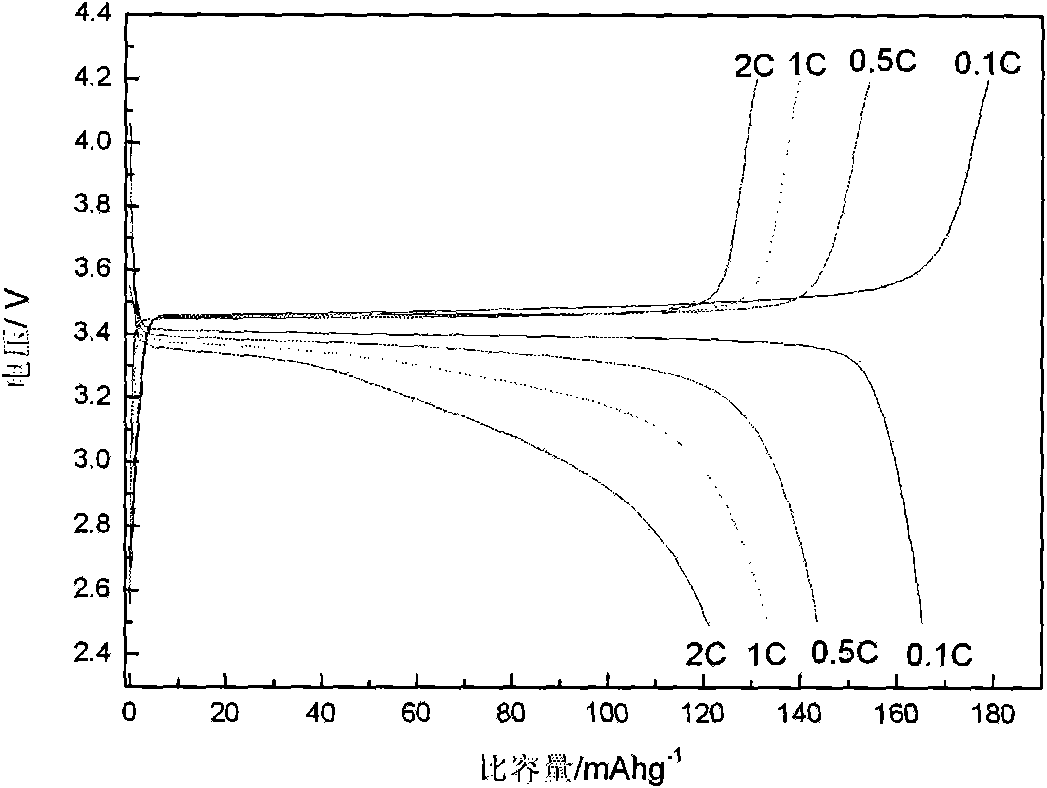

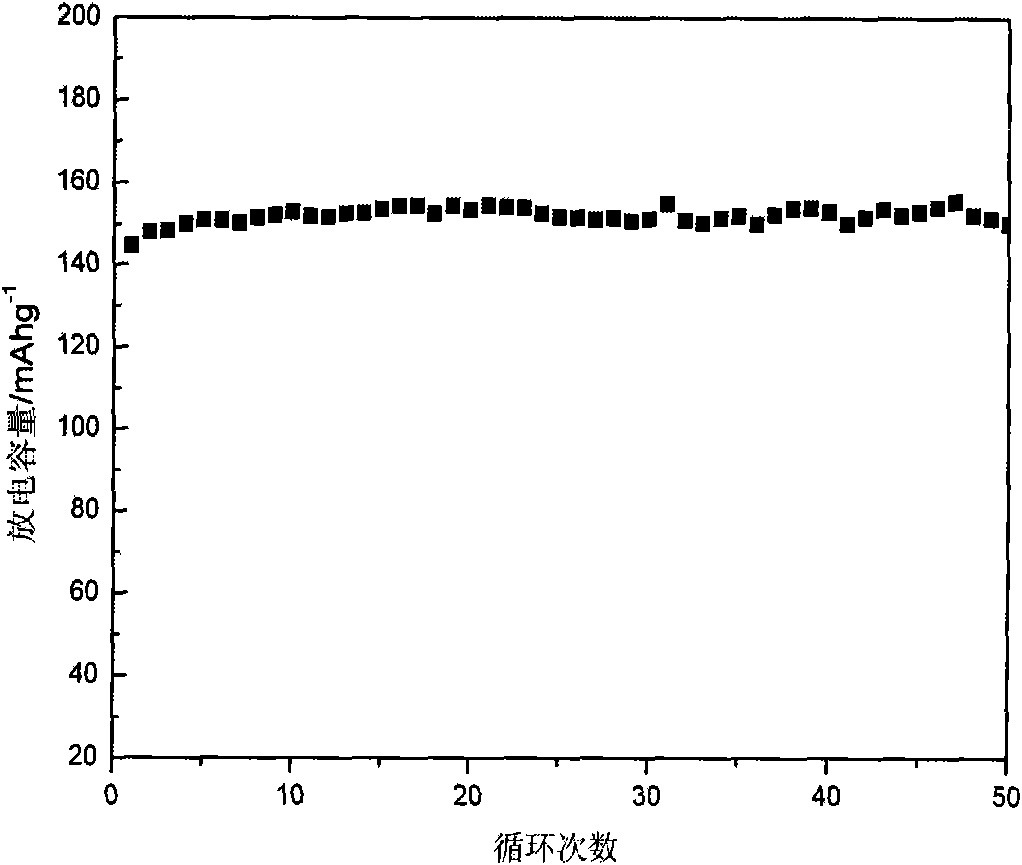

Image

Examples

Embodiment 1

[0031] A preparation method of lithium iron phosphate lithium ion battery cathode material, the method comprising:

[0032] Lithium, iron, phosphorus and magnesium are respectively weighed lithium hydroxide monohydrate, ferrous oxalate, phosphoric acid and magnesium hydroxide according to the molar ratio of 1.05:1:1:0.05, and lithium hydroxide monohydrate, ferrous oxalate 5 times the weight of iron and phosphoric acid in deionized water, add lithium hydroxide monohydrate and magnesium hydroxide to deionized water, add phosphoric acid and mix, adjust pH=3.2 by adding oxalic acid and ammonia water. Add corresponding sucrose according to the theoretical carbon content of 3wt% in the final product, dissolve it completely, stir and mix evenly, add ferrous oxalate and mix evenly to obtain a mixed slurry, and quickly dry to obtain a reaction precursor;

[0033] After ball milling on the planetary ball mill for 2h, it was transferred to a tube furnace at 95v%Ar+5v%H 2 In the atmosphe...

Embodiment 2

[0039] A preparation method of lithium iron phosphate lithium ion battery cathode material, the method comprising:

[0040]Lithium, iron, and phosphorus are respectively weighed lithium acetate, ferrous acetate, and phosphoric acid according to a molar ratio of 1:1:1, and the phosphoric acid is diluted with deionized water that is twice the weight of lithium acetate, ferrous acetate, and phosphoric acid, and then Add lithium acetate while stirring, and adjust the pH of the solution to 3.2 by adding acetic acid and urea dropwise. After the solution system is stable, add the corresponding epoxy resin according to the carbon content of 6wt%, to make it all dissolve, stir and mix evenly, and dry quickly , to obtain a complex containing lithium and phosphorus;

[0041] Mix the obtained composite powder with ferrous acetate evenly to obtain a precursor. After ball milling for 4 hours, transfer it to a tube furnace in N 2 In the atmosphere, the precursor was pre-fired at 350°C for 1...

Embodiment 3

[0046] A preparation method of lithium iron phosphate lithium ion battery cathode material, the method comprising:

[0047] Lithium, iron, phosphorus and zirconium were weighed lithium hydroxide, ferric oxide, ammonium dihydrogen phosphate and zirconium acetate respectively according to the molar ratio of 1:1:1:0.1, and the ammonium dihydrogen phosphate and lithium hydroxide The two raw materials were respectively dissolved in deionized water with six times the weight of lithium hydroxide, ferric oxide, and ammonium dihydrogen phosphate, and then the two solutions were slowly mixed, zirconium acetate was added, and the pH was adjusted to 3.5 by adding oxalic acid. According to the final product Add the corresponding polyvinyl alcohol with a carbon content of 15wt% to dissolve it completely, stir and mix evenly, add ferric oxide to obtain a uniform slurry, and use a rapid drying method to obtain a reaction precursor with uniform distribution of lithium, iron, and phosphorus. . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com