Method for modified cladding composite, anode material LiCoO* of lithium ion battery, and batteries

A lithium-ion battery and positive electrode material technology, applied in the field of material chemistry, can solve the problems of particle size and surface change, positive electrode material specific capacity decrease, slurry processing behavior deterioration, etc., to achieve or make up for inherent defects and improve inherent Defects, effects of stabilizing charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

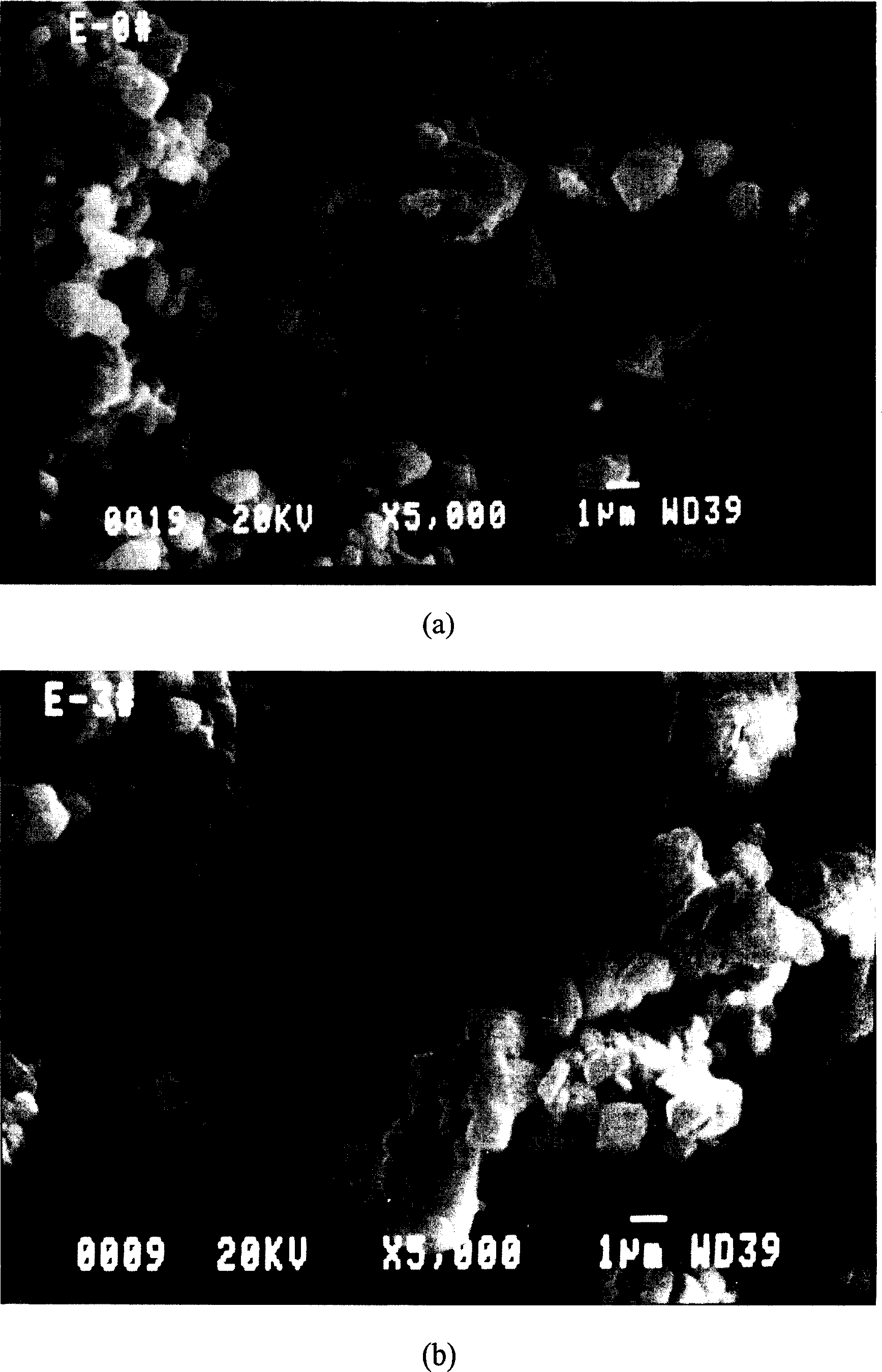

[0040] Embodiment one, LiOH, HBO 3 , Al(NO 3 ) 3 Dissolve in water to prepare a 1% solution at a molar ratio of 2:1:1, and dry 100g LiCoO 2 Add the powder into 45g of the above solution, stir for 20min, then add 150g of PEO solution with a concentration of 1% and a molecular weight of 250,000, and continue stirring for 30min. Then, the slurry was heated at 70° C. and stirred while heating to evaporate water. Then the LiCoO 2 Put it into an oven at 60°C and bake for 6-8 hours, and then treat it in a calciner at 700°C for 6 hours to obtain the coated conductive glass layer of the present invention 0.5Li 2 O 0.25Al 2 o 3 0.25B 2 o 3 After LiCoO 2 Material. Depend on figure 1 a, b can clearly see the coated LiCoO 2 Compared with LiCoO before coating 2 The particles are uniform and the surface is smooth.

Embodiment 2

[0041] Embodiment two, 0.98g LiOH is dissolved in 100g water and adds 1.96g H 4 SiO 4 Stir and add 14.3 g of 10% NH 3 ·H 2 O until completely dissolved. 200g LiCoO 2 The powder was added to the solution and stirred for 30 minutes, then heated at 80°C to evaporate the water. Then put the material into an oven at 80°C and bake for 10 hours. 100 g of a 3% polyacrylate solution was prepared with CMC as a solvent. Add the material to this solution and stir for 40 minutes, then heat to evaporate the solvent. Put the material into a calcination furnace and treat it at 900 ° C for 8 hours to obtain the coated conductive glass layer of the present invention 0.5Li 2 O 0.5SiO 2 After LiCoO 2 Material.

Embodiment 3

[0042] Embodiment three, 1.47g LiOH is dissolved in 100g water, add 1.47g H 4 SiO 4 Stir until completely dissolved, then add 6.25g Al(NO 3 ) 3 . After dissolving, add 200g LiCoO to this solution 2 Stir the powder for 20min, add 10% NH 3 ·H 2 O 31g was continued to stir for 30min, and then 200g of 1.3% PEO solution was added to continue to stir for 30min. After that, the water was evaporated by heating at 60°C. Put it in an oven at 100°C and bake it for about 8 hours, then put it in a calciner and treat it at 900°C for 8 hours to get the coated conductive glass layer of the present invention 0.5Li 2 O 0.25Al 2 o 3 0.25SiO2 2 After LiCoO 2 Material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com