Negative electrode active material and negative electrode for lithium ion secondary battery

A negative electrode active material, secondary battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of short cycle life, low compaction density, low gram capacity of negative electrode active materials, etc., to improve electrical conductivity, The effect of reducing contact resistance and shortening the transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the negative electrode active material for lithium ion secondary battery of the present invention includes the following steps:

[0029] 1. The mass ratio of spherical graphite and total artificial graphite is 5:95~95:5 (the ratio of massive artificial graphite and needle-shaped artificial graphite is 5:95~95:5), and the mass ratio of the mixed matrix 1-20% pitch or resin, put the total weight of spherical graphite, block artificial graphite, needle-shaped artificial graphite, pitch or resin and solvent in the mixer at a ratio of 1-10 liters / Kg, at 500-2000r Mix for 30~240min at a rotation speed of / min to obtain a mixed emulsion;

[0030] 2. Fuse the mixed emulsion in a fusion machine at a speed of 300 ~ 3000r / min and a fusion temperature of 20 ~ 100 ℃ for 30 ~ 240 min to obtain a fusion precursor;

[0031] The solvent is one or a mixed solvent of water, ethanol, isopropanol, glycerol, acetone, toluene, or xylene.

[0032] 3. Under the protection of ...

Embodiment 1

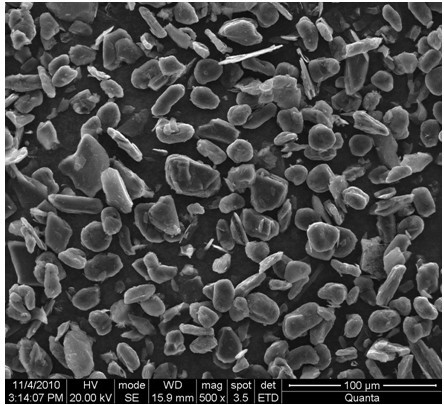

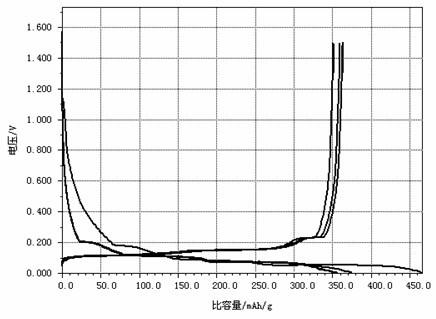

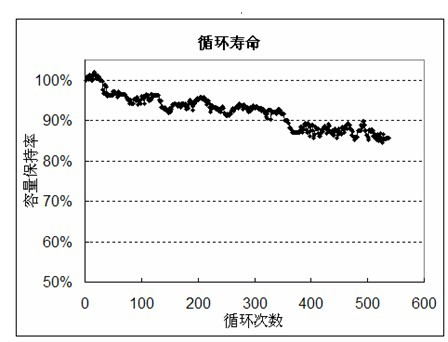

[0048] Such as figure 1 , 2 , 3 shows, in the mixer, the mass ratio of spherical graphite is 3:2: the total amount of artificial graphite (the ratio of massive artificial graphite to needle-shaped artificial graphite in artificial graphite is 3:2), and the graphite mass is 5% Mix the asphalt with 10L / kg of total solid mass of water, and mix for 120min at a speed of 1000r / min to obtain a mixed emulsion; put the mixed emulsion in a fusion machine at a speed of 2500r / min and a fusion temperature of 60℃ Fusion precursor is obtained by fusion for 30 minutes under argon protective gas; the fusion precursor is placed in a high-temperature furnace at 10°C / min to 800°C for 16 hours, and then cooled to 5°C / min at a cooling rate Room temperature; graphitization heat treatment is performed at 3000° C. to obtain a negative electrode active material for a lithium ion secondary battery.

Embodiment 2

[0050] In the mixer, the spherical graphite with a mass ratio of 5:3: the total amount of artificial graphite (the ratio of massive artificial graphite to needle-shaped artificial graphite in artificial graphite is 1:1), graphite mass 10% pitch and 8L / The total mass of kilograms of solid acetone is mixed and mixed for 60 minutes at a rotation speed of 1200r / min to obtain a mixed emulsion; the mixed emulsion is fused in a fusion machine at a rotation speed of 2000r / min and a fusion temperature of 80°C for 15 minutes. The fusion precursor is obtained; the fusion precursor is placed in a high temperature furnace at 8°C / min to 600°C for 24 hours, and then cooled to room temperature at a cooling rate of 3°C / min; then at 2900°C After performing graphitization heat treatment, an anode active material for a lithium ion secondary battery is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram capacity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com