Multi-element in-situ co-doped ternary material precursor as well as preparation method and application thereof

A ternary material, co-doping technology, applied in chemical instruments and methods, electrical components, inorganic chemistry, etc., can solve the problems of easy change of crystal structure, difficult doping ion distribution, unstable crystal structure, etc. The effect of easy large-scale industrial production, excellent cycle performance, and excellent rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

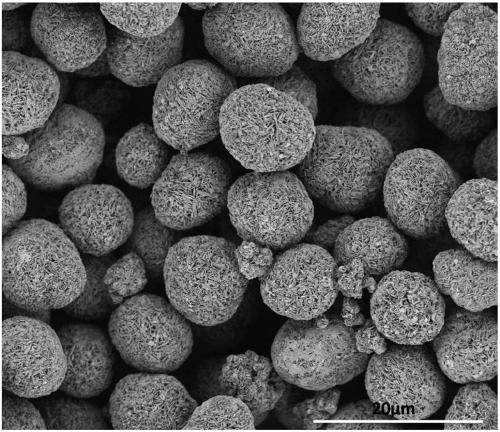

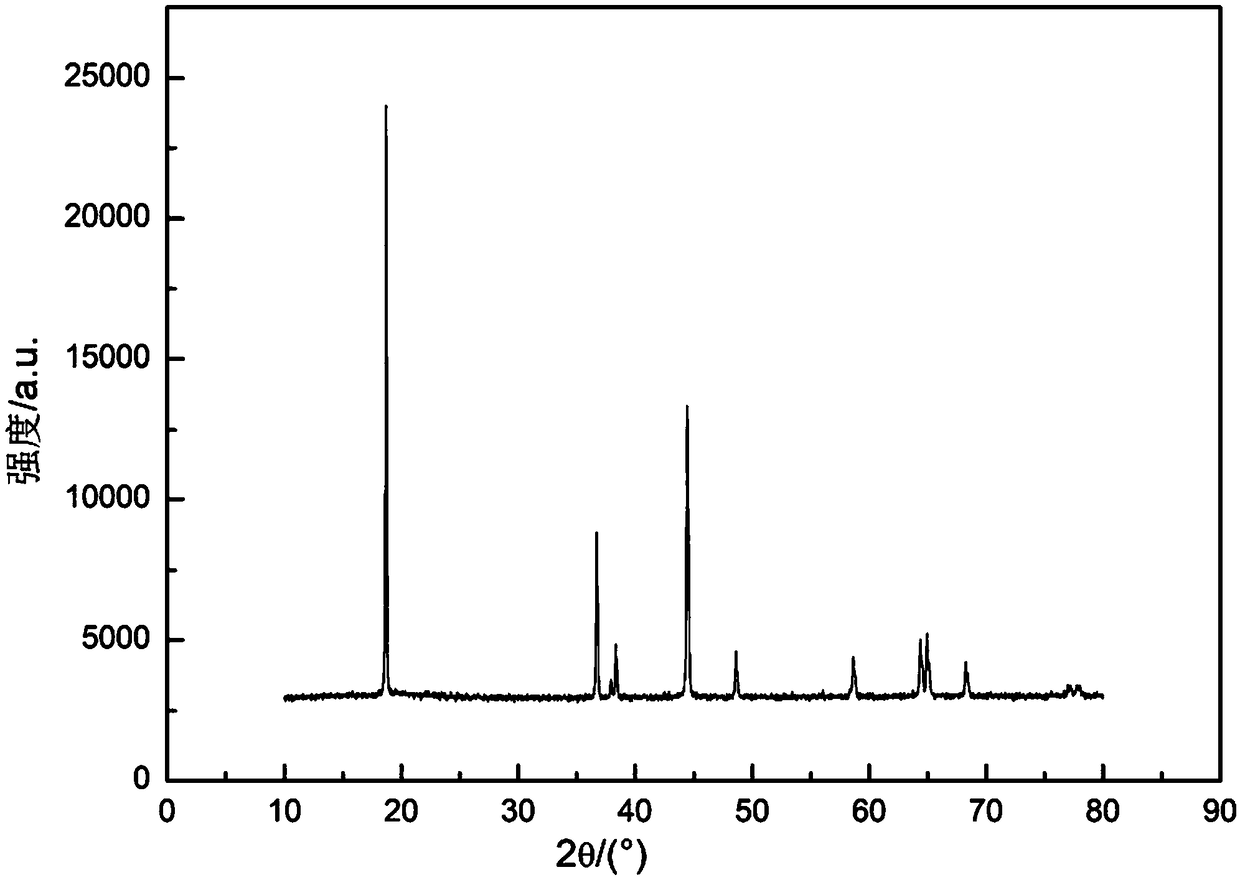

[0036] This embodiment prepares Zr 4+ with Al 3+ Co-doped modified ternary precursor (Ni 0.6 co 0.2 mn 0.2 ) 0.993 Zr 0.003 Al 0.004 (OH) 2.01 and ternary cathode material Li(Ni 0.6 co 0.2 mn 0.2 ) 0.993 Zr 0.003 Al 0.004 o 2 , including the following steps:

[0037] (1) Preparation of metal salt solution: Weigh 8.937mol nickel sulfate hexahydrate, 2.979mol cobalt sulfate heptahydrate, 2.979mol manganese sulfate monohydrate, 0.03mol aluminum sulfate octadecahydrate, 0.045mol zirconium sulfate tetrahydrate, dissolve in appropriate amount In pure water, 10 liters of salt solution A was prepared, and the total metal ion concentration in the salt solution was 1.5 mol / L.

[0038] (2) Precipitating agent preparation: Weigh 40 mol of sodium hydroxide, dissolve in pure water, and prepare 10 liters of sodium hydroxide aqueous solution B with a concentration of 4 mol / L.

[0039] (3) Complexing agent preparation: use ammonia water as a complexing agent, take an appropriat...

Embodiment 2

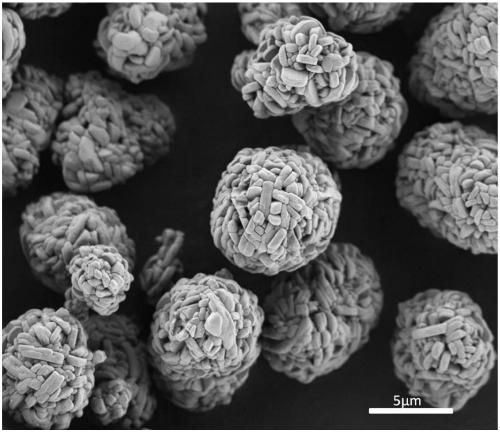

[0049] In this embodiment, the ternary cathode material LiNi 0.5 co 0.2 mn 0.3 o 2 (NCM523) as the substrate to prepare Zr 4+ , Zn 2+ with Al 3 + Co-doped ternary cathode material Li(Ni 0.5 co 0.2 mn 0.3 ) 0.99 Zr 0.003 Zn 0.002 Al 0.005 o 2 , including the following steps:

[0050] (1) Metal salt solution preparation: Weigh 9.9mol nickel sulfate hexahydrate, 3.96mol cobalt sulfate heptahydrate, 5.94mol manganese sulfate monohydrate, 0.05mol aluminum sulfate octadecahydrate, 0.06mol zirconium sulfate tetrahydrate, 0.04mol seven Zinc sulfate in water is dissolved in an appropriate amount of pure water to prepare 10 liters of metal salt solution A, and the total metal ion concentration in the solution is 2.0mol / L.

[0051] (2) Precipitating agent preparation: Weigh 60 mol of sodium hydroxide, dissolve in pure water, and prepare 10 liters of sodium hydroxide aqueous solution B with a concentration of 6 mol / L.

[0052] (3) Complexing agent preparation: use ammonia ...

Embodiment 3

[0058] In this embodiment, the ternary cathode material LiNi 0.6 co 0.2 mn 0.2 o 2 (NCM622) as the substrate, prepare Mg 2+ 、Sc 3+ 、Al 3+ with Ti 4+ Co-doped ternary cathode material Li(Ni 0.6 co 0.2 mn 0.2 ) 0.99 Mg 0.003 sc 0.002 al 0.004 Ti 0.001 o 2 , including the following steps:

[0059] (1) Metal salt solution preparation: Weigh 5.94mol nickel sulfate hexahydrate, 1.98mol cobalt sulfate heptahydrate, 1.98mol manganese sulfate monohydrate, 0.03mol magnesium sulfate, 0.02mol aluminum sulfate octadecahydrate, 0.01mol octahydrate Scandium sulfate and 0.01mol titanium tetrachloride were dissolved in an appropriate amount of pure water to prepare 10 liters of metal salt solution A. The total metal ion concentration in the salt solution was 1 mol / L.

[0060] (2) Precipitating agent preparation: Weigh 30 mol of sodium hydroxide, dissolve in pure water, and prepare 10 liters of sodium hydroxide aqueous solution B with a concentration of 3 mol / L.

[0061] (3) Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com