Method for producing positive electrode active material for lithium ion battery, positive electrode active material for lithium ion battery, electrode for lithium ion battery, and lithium ion battery

A positive electrode active material and lithium-ion battery technology, applied in battery electrodes, lithium batteries, secondary batteries, etc., can solve the problems of unsuitable electrode materials, low discharge voltage, etc., to improve initial discharge capacity, improve conductivity, improve Effect of high-speed charging and discharging characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

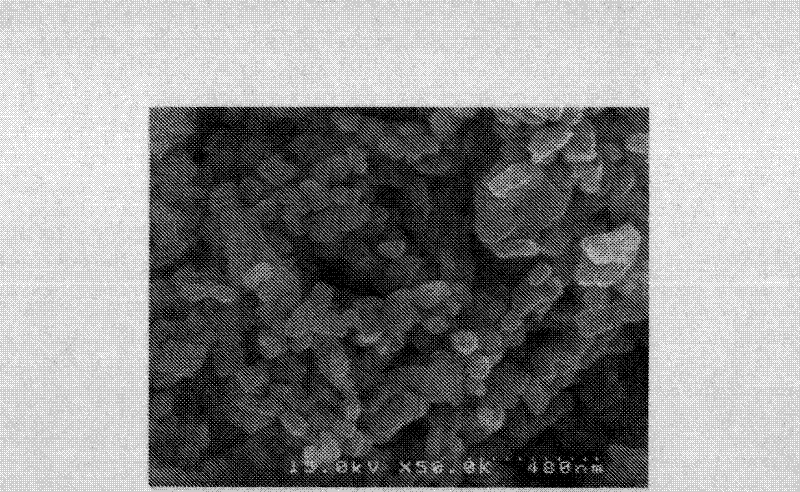

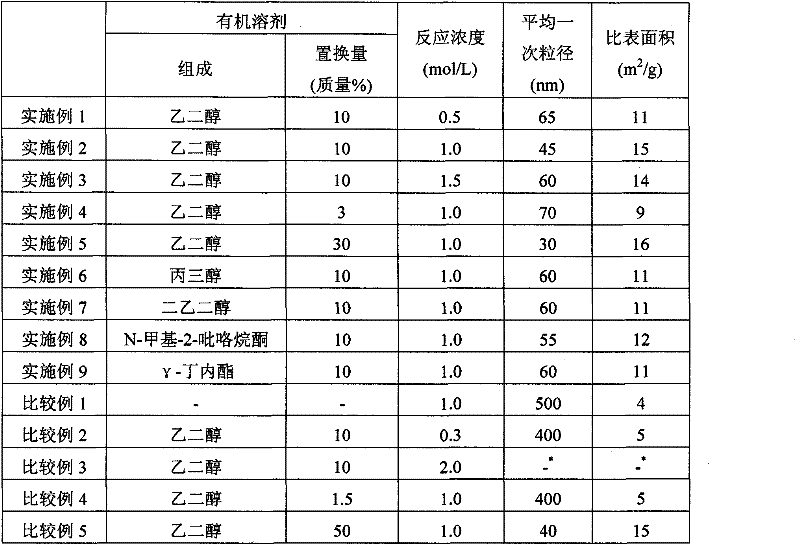

[0097] "Example 1"

[0098] Add 3 mol of lithium chloride (LiCl) and 1 mol of phosphoric acid (H 3 PO 4 ) and stirred to obtain lithium phosphate (Li 3 PO 4 ) slurry.

[0099] Next, add 1 mol of iron (II) chloride (FeCl 2 ), using ethylene glycol to replace a part of the water in the slurry in such a manner that the total feed mass of the hydrothermal reaction is 10% by mass, and then add water to make a raw material solution of a total amount of 2L (the total feed mass of the hydrothermal reaction) . In addition, if the reaction concentration of the raw material solution is converted to LiFePO 4 , then becomes 0.5mol / L.

[0100] Next, in order to carry out a hydrothermal reaction, the raw material liquid was put into an autoclave, and after introducing an inert gas, it heated at 180 degreeC and 1.2 MPa for 6 hours to make it react, and filtered and separated the solid and liquid after that.

[0101] Next, the same amount of water as the mass of the separated solid sub...

Embodiment 2

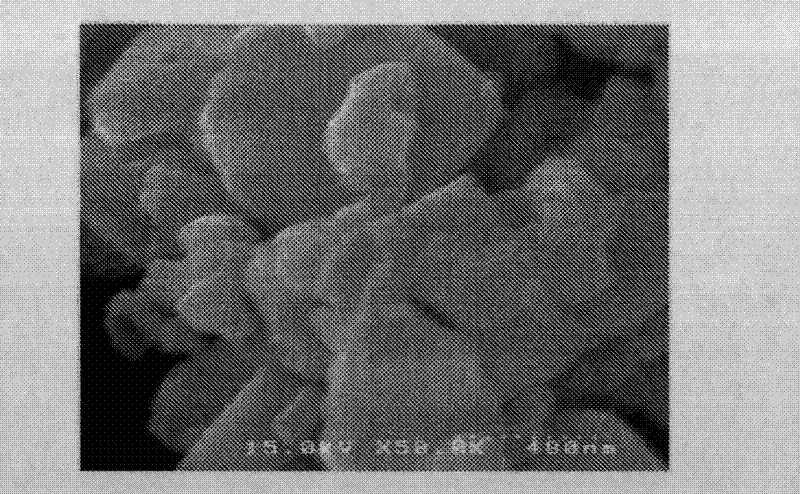

[0104] "Example 2"

[0105] In addition to LiFePO 4 In terms of conversion, the reaction concentration of the raw material solution is set to 1.0 mol / L, that is, the amount of the raw material (lithium chloride, phosphoric acid, and iron (II) chloride) is doubled and the total amount of the raw material solution is adjusted to 2 L. According to Example 1, the positive electrode active material for lithium ion batteries of Example 2 was produced.

Embodiment 3

[0106] "Example 3"

[0107] In addition to LiFePO 4 In terms of conversion, except that the reaction concentration of the raw material solution is set to 1.5 mol / L, that is, except that the amount of the raw material is increased to 1.5 times and the total amount of the raw material solution is adjusted to 2L, the lithium ion of Example 3 is produced according to Example 1. Positive electrode active material for batteries.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com