Preparation method of lithium ionic cell positive pole material ferric phosphate lithium

A lithium-ion battery, lithium iron phosphate technology, applied in electrode manufacturing, battery electrodes, chemical instruments and methods, etc., can solve problems such as poor shape and poor electrical performance, and avoid complex processes, good shape, and gas production. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

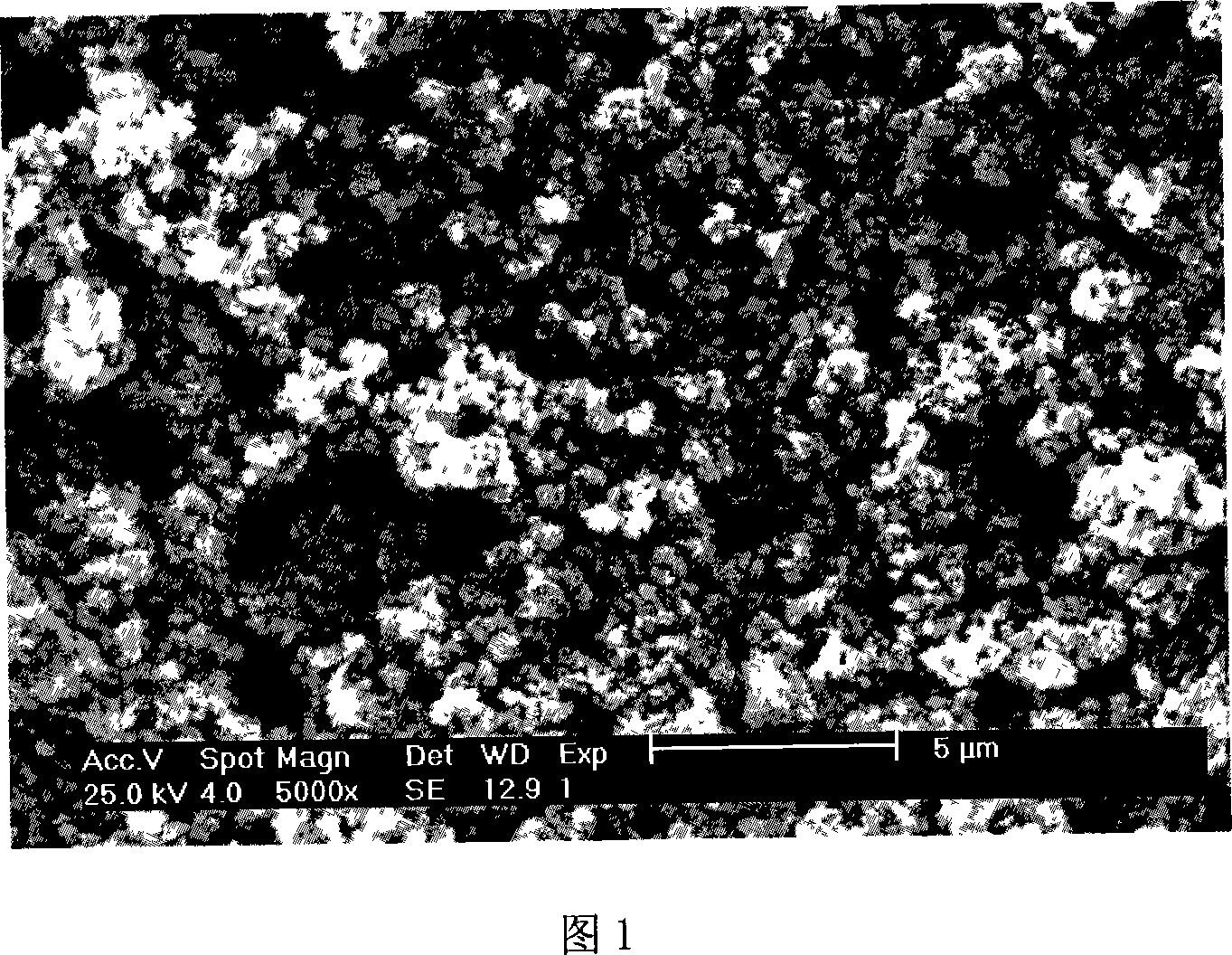

Image

Examples

Embodiment 1

[0019] Using iron oxalate and lithium dihydrogen phosphate according to Fe:Li:PO 4 After the mol ratio of =0.8: 1: 1 is mixed directly, add the acetone of 2 times of the total weight of the above-mentioned substances, carry out ball milling in ball mill for 2 hours, after the slurry after ball milling is dried, pulverized, granulated, the surface pressure is 0.01Kg / cm 3 In the compacted state, it is calcined at 500°C for 30 hours to make lithium iron phosphate material products.

Embodiment 2

[0021] Use iron acetate and lithium dihydrogen phosphate according to Fe:Li:PO 4 =1.2: 1: After the molar ratio of 1 is mixed directly, add the acetone of 5 times of the total weight of the above-mentioned substances, carry out ball milling in ball mill for 20 hours, the slurry after ball milling is through drying, pulverizing, granulating, and the surface pressure is 5Kg / cm 3 In the compacted state, it is calcined at 800°C for 2 hours to make lithium iron phosphate material products.

Embodiment 3

[0023] Use iron stearate and lithium dihydrogen phosphate according to Fe:Li:PO 4 After the molar ratio of =1:1:1 is mixed directly, add the acetone of 3 times of the total weight of the above-mentioned substances, carry out ball milling in the ball mill for 5 hours, the slurry after the ball milling is through drying, pulverizing, granulating, and the surface pressure is 1Kg / cm 3 In the compacted state, it is calcined at 750°C for 12 hours to make lithium iron phosphate material products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com