Semiwet method of preparing lithium ferrous phosphate and its prepared lithium ferrous phosphate

A lithium iron phosphate, semi-wet technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of difficulty in determining the grinding time, inability to continuous production, uneven products, etc., and achieve uniform product performance. , stable quality, uniform mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Choose FeC among the compounds containing Li, Fe, P 2 o 4 .2H 2 O is used as a water-insoluble compound and a newly prepared nanoparticle precipitate (without drying operation) is used. The preparation method is as follows: Weigh FeCl 2 .4H 2 O (content 99.8%) 25kg, dissolve in 50Kg water, weigh H in addition 2 C 2 o 4 .H 2 O (content 99%) 16.3kg, be dissolved in 60Kg, 50 ℃ of hot waters, under 120 rev / min stirring speeds, two kinds of solutions are combined in 240 liters of reactors, adjust PH=4 with ammonia water; After the reaction is finished, continue Stir for 1-3 hours, wash the precipitate three times by decantation, transfer it to a centrifuge, dry it and wash it with deionized water until it is washed with 0.1% AgNO 3 Check that the lotion has no white precipitate, weighs 27.37kg, and analyzes the content of FeC 2 o 4 .2H 2 O 79.96%, thus calculated to contain 121.65 moles of iron; 121.65 moles of Li is equivalent to LiOH.H 2 O (99.5%) 5.13kg; 121...

Embodiment 2

[0047] 1. in the compound containing Li, Fe, P, choose ferrous carbonate fine powder to make water-insoluble compound, take by weighing particle diameter and be the ferrous carbonate (containing Fe 38%) micropowder 17kg below 10 microns, contain Fe 115.67 moles; 113.36 moles of Li converted to Li(CH 3 COO).2H 2 O (99.5%) 11.62kg, 115.67 moles of P-equivalent NH 4 h 2 PO 4 (99.0%) 13.44kg and the MgO (98.5%) 47.33g that the Mg of 1.157 moles is converted into, under stirring, Li(CH 3 COO).2H 2 O (99.5%) 11.62kg and NH 4 h 2 PO 4 (99.0%) 13.44kg is dissolved in 30kg, 60kg respectively and temperature is made into solution in 50 ℃ of hot water; Under agitation, two kinds of solutions are added into reactor concurrently, then 17kg ferrous carbonate (containing Fe 38%) micropowder Mix and ball mill with 47.33g MgO (98.5%) evenly, then add in the above-mentioned co-current solution under stirring condition, stir evenly, make suspension;

[0048] 2. Add to the above suspensi...

Embodiment 3

[0053] 1. Choose FePO among the compounds containing Li, Fe, and P 4 .4H 2 O as water-insoluble compound and using freshly prepared nanoparticle precipitates: Weigh Fe(NO 3 )3 .9H 2 O (content 98%) 54.9kg, dissolved in 40Kg of 50 ℃ hot water, another weighed (NH 4 ) 2 HPO 4 (content 99.8%) 17.62kg, be dissolved in 50kg 50 ℃ of hot waters, under 120 rev / min stirring speeds, two kinds of solutions are combined, adjust PH=5-6 with ammonia water, after reaction is finished, clean precipitation with decantation Three times, move into a centrifuge to dry, weigh the solution to combine, adjust PH=5-6 with ammonia water, after the reaction is completed, wash the precipitate three times by decantation, move into a centrifuge to dry, weigh 34.32kg, analyze the FePO content 4 .4H 2 O (82.5%), which is calculated to contain Fe or P 127.04mol; the Li mole number is 96% of Fe or P, that is, 121.96mol, and Li 3 (C 6 h 5 o 7 ).4H 2 O(99.5%)【(121.96×281.98)÷3】÷0.995=11.52kg, doping ...

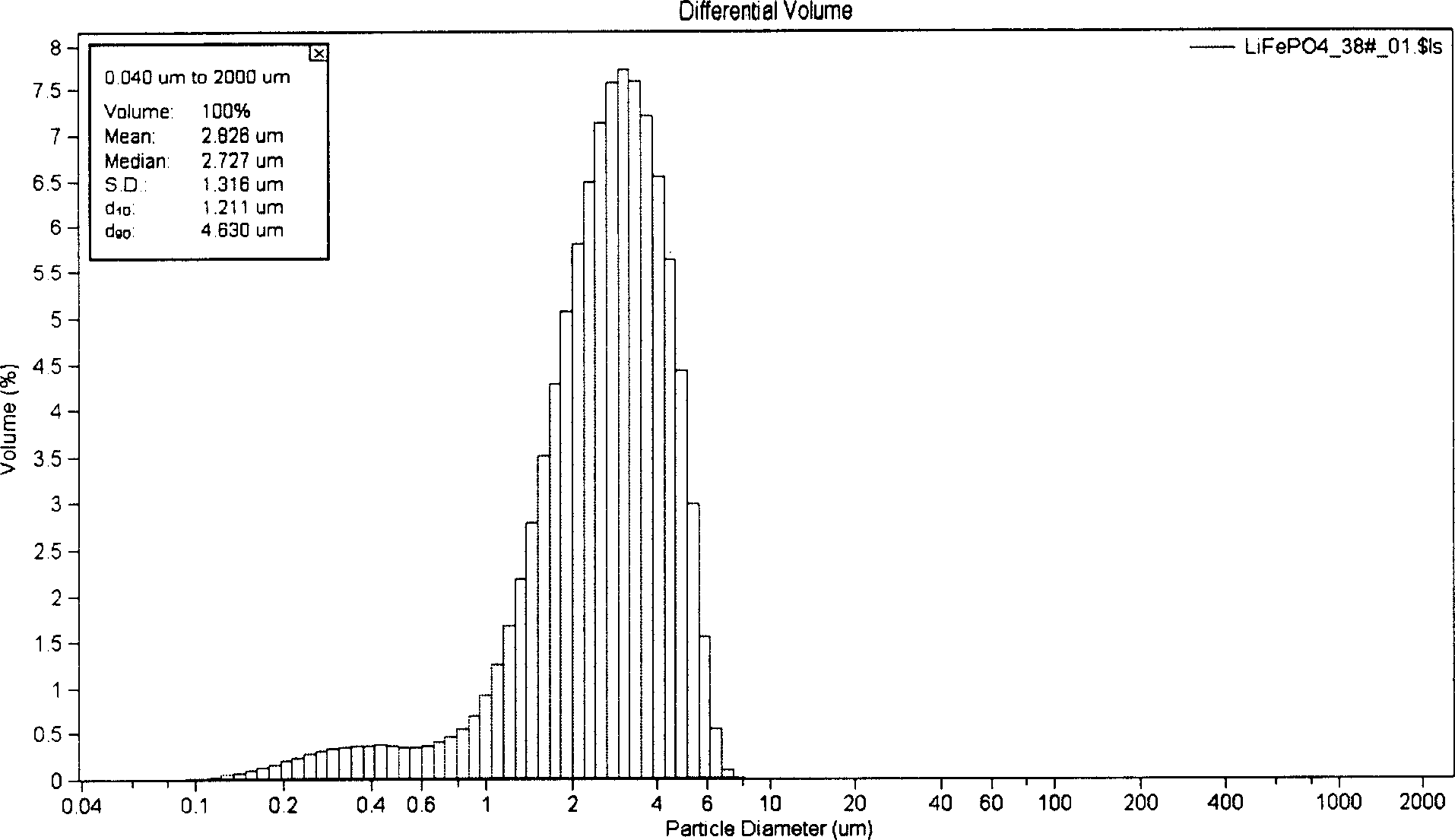

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com