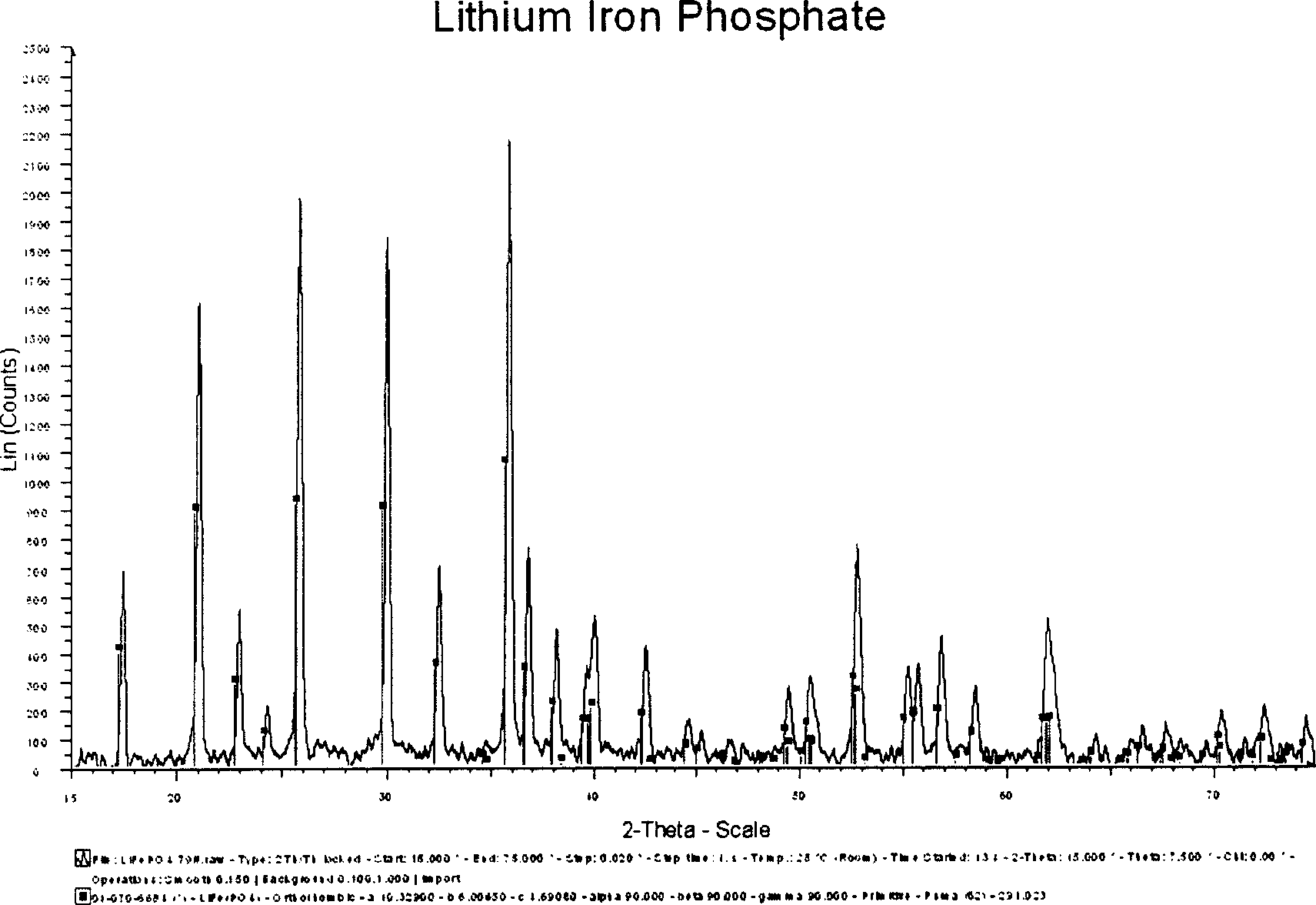

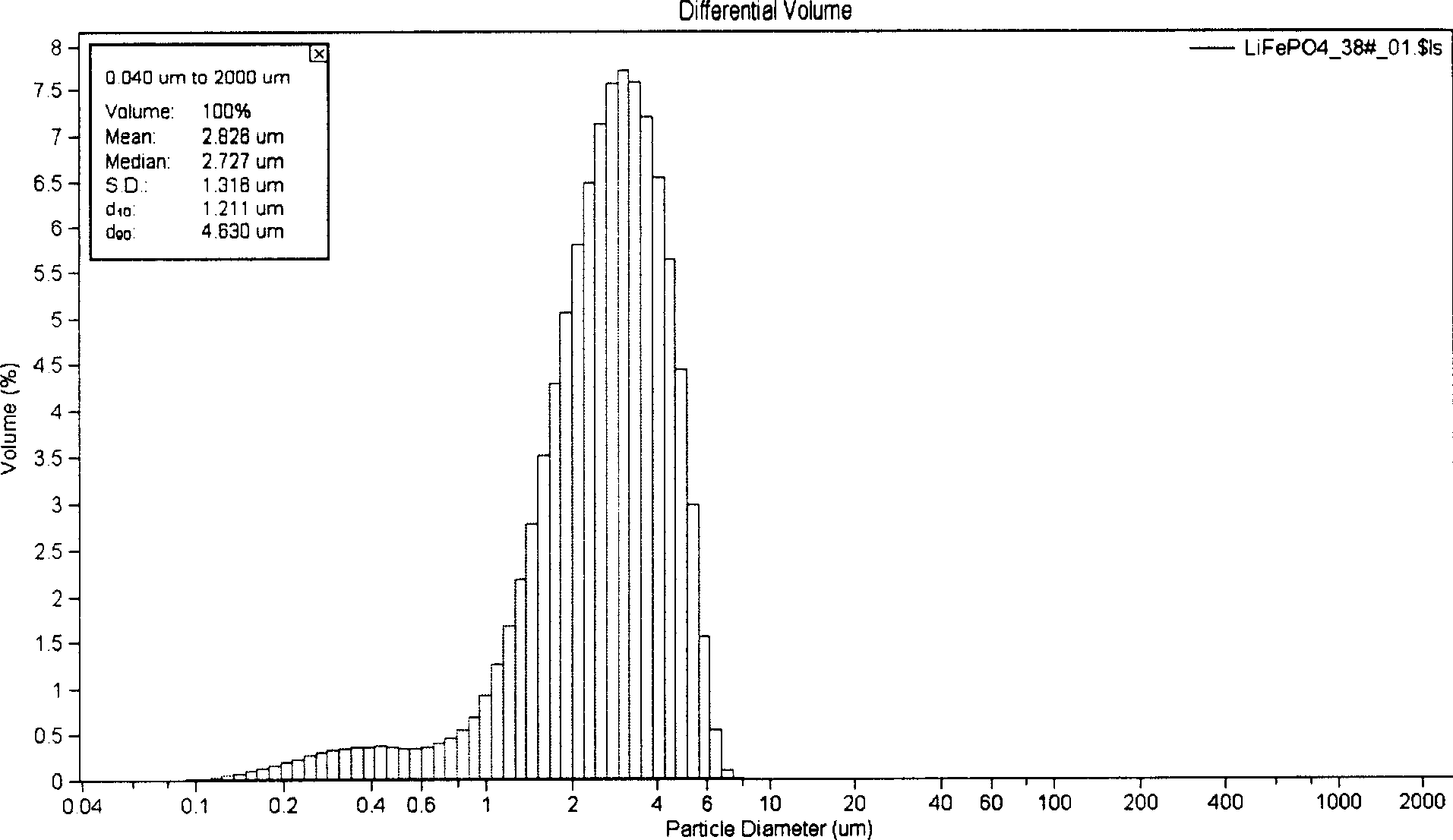

Wet method of preparing lithium ferrous phosphate and its prepared lithium ferrous phosphate

A lithium iron phosphate, wet process technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of difficulty in determining the uniform mixing time, continuous production, and prolonged grinding time, and avoid product performance. Uneven, good rate discharge performance and cycle performance, the effect of uniform mixing of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. First prepare m=p=q=126.77 moles of solutions containing Li, Fe, P compounds, that is, LiOH.H 2 O (99.8%) 5.33kg, Fe (CH 3 COO) 2 .4H 2 O (99%) 31.50kg, H 3 PO 4 (85%) 14.62kg, be dissolved in 40,50,30kg respectively and temperature is 50 ℃ water and make solution; Above-mentioned three kinds of solutions are added into 240 liters of reactors concurrently, make it mix under 120 rev / min stirring speeds Carry out the deposition reaction of formula (4) evenly and rapidly:

[0050] (4)

[0051] The main product and each by-product form a suspension together;

[0052] 2. Add the reducing conductive additive under the condition of the stirring speed of 120 rpm, it is estimated that LiFePO 4 Yield = 126.77×157.76, about 20kg; while stirring, add 15%-3.0kg of the expected product weight to the suspension to produce carbon compounds and inert metal compounds. The content of the inert metal in the compound is the expected product weight 1% of - namely 0.51kg iner...

Embodiment 2

[0059] 1. First prepare respectively m=124.27 moles, p=q=126.80 moles containing Li, Fe, the solution of P compound, be about to 124.26 moles of LiCl (99.6%) 5.29kg, 126.80 moles of FeCl 2 .4H 2 O (99.5%) 25.34kg, 126.80 moles of (NH 4 ) 3 PO 4 .3H 2 O (99.5%) 25.89kKg, respectively dissolved in 15, 30, 80Kg and the temperature is 50 ℃ water to make a solution, and 1.268 moles of MgCl 2 .6H 2 O (98%) 263.05g dissolved in FeCl 2 In the solution; under 120 rev / min stirring speeds, divide above-mentioned three kinds of solutions and flow into 240 liters of reactors, make it mix uniformly and carry out rapidly (3 1 ) deposition reaction of formula:

[0060] (3 1 )

[0061] At this moment, the reaction product and the by-product form a suspension together;

[0062] 2. Add the reducing conductive additive under the condition of 120 rpm speed of the agitator, it is estimated that Li 0.98 Mg 0.01 FePO 4 The output is approximately equal to 126.8×157.76, that is,...

Embodiment 3

[0067]1. First prepare respectively m=120.96 moles, q=p=126.00 moles containing Li, Fe, the solution of P compound and the solution containing Zr1.26 moles, that is to say, LiH containing 120.96 moles of Li and P 2 PO 4 (98.8%) 12.724kg and 5.04 moles of phosphorus (NH 4 )H 2 PO 4 (99.5%) 0.583kg together, containing 126.00 moles of Fe (C 3 h 5 o 3 ) 2 .3H 2 O (containing Fe18.9%) 37.23kg and Zr (NO containing 1.26 moles of Zr 3 ) 4 ·5H 2 O (99%) 0.546.5kg is dissolved in 60, 60, 5kg respectively and the hot water that temperature is 50 ℃ makes solution; Under 120 rpm stirring speed, above-mentioned three kinds of solutions are added into 240 liters of reactors in parallel flow mode medium, to mix well and go quickly (3 2 ) deposition reaction of formula:

[0068] (3 2 )

[0069] At this moment, the reaction product and the by-product form a suspension together;

[0070] 2. Add the reducing conductive additive under the condition of 120 rpm speed of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com