Method for preparing lithium ion battery anode material nickle cobalt lithium manganate

A technology of nickel-cobalt lithium manganese oxide and lithium-ion batteries, which is applied in the field of preparation of lithium-ion battery cathode materials, can solve problems such as difficulty in mixing materials uniformly, slow solid phase diffusion speed, and influence on practical applications, and achieve high tap density, The effect of excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

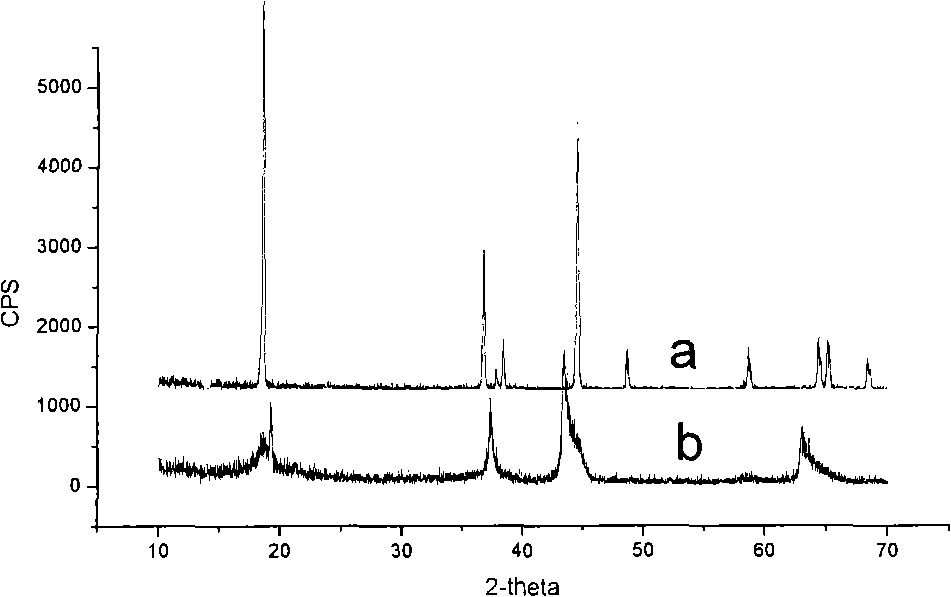

[0027] Example 1 Take 5 mol each of nickel hydroxide, electrolytic manganese dioxide, and lithium cobaltate, and put them into a 10-liter hydrothermal kettle. Place 8 liters of lithium hydroxide solution in advance in the hydrothermal kettle, lithium ion concentration 25g / l. After heating to 250° C. for 5 hours, cooling to normal temperature, and filtering the washing slurry. After drying the slurry, analyze its Li / M (lithium and transition metal element molar ratio) to be 0.92. Lithium carbonate was supplemented to make Li / M 1.10, added to a ball mill, ground for 2 hours, and then roasted. The roasting system is as follows: heating up to 1020°C at a rate of 3°C / min for 10 hours, and cooling at a cooling rate of 3°C / min to obtain nickel-cobalt-lithium manganese oxide products. The resulting product shows that its phase is a layered structure through X-ray diffraction analysis; the tap density is 2.55g / cm 3 ; The product is made into R2016 button battery and tested, 0.5C cha...

Embodiment 2

[0028] Example 2 Take 5 mol each of nickel oxide, trimanganese tetraoxide, and lithium cobaltate, and add them into a 10-liter hydrothermal kettle. Place 8 liters of lithium hydroxide solution in advance in the hydrothermal kettle, lithium ion concentration 18g / l. After heating to 150° C. for 10 hours, cooling to normal temperature, and filtering the washing slurry. After drying the slurry, its Li / M was analyzed to be 0.93. Lithium carbonate was supplemented to make Li / M 1.08, added to a ball mill and ground for 2 hours, then roasted. The roasting system is as follows: heating up to 1000°C at a rate of 3°C / min for 15 hours, and cooling the material at a cooling rate of 3°C / min to obtain nickel-cobalt-lithium manganese oxide products. The resulting product shows that its phase is a layered structure through X-ray diffraction analysis; the tap density is 2.60g / cm 3 ; The product is made into R2016 button battery and tested, 0.5C charge and discharge, its initial discharge cap...

Embodiment 3

[0029] Example 3 Take 5 mol each of nickel hydroxide, trimanganese tetraoxide, and lithium cobaltate, and put them into a 10-liter hydrothermal kettle. Place 8 liters of lithium hydroxide solution in advance in the hydrothermal kettle, lithium ion concentration 30g / l. After heating to 130° C. for 18 hours, cooling to normal temperature, and filtering the washing slurry. After drying the slurry, analyze its Li / M to be 0.91. Lithium carbonate was supplemented to make Li / M 1.06, added to a ball mill and ground for 2 hours, then roasted. The roasting system is as follows: the temperature is raised to 1050°C at a speed of 5°C / min for 15 hours, and the material is cooled with the furnace to obtain nickel-cobalt-lithium manganese oxide products. The resulting product shows that its phase is a layered structure through X-ray diffraction analysis; the tap density is 2.58g / cm 3 ; The product is made into R2016 button battery and tested, 0.5C charge and discharge, its initial discharg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com