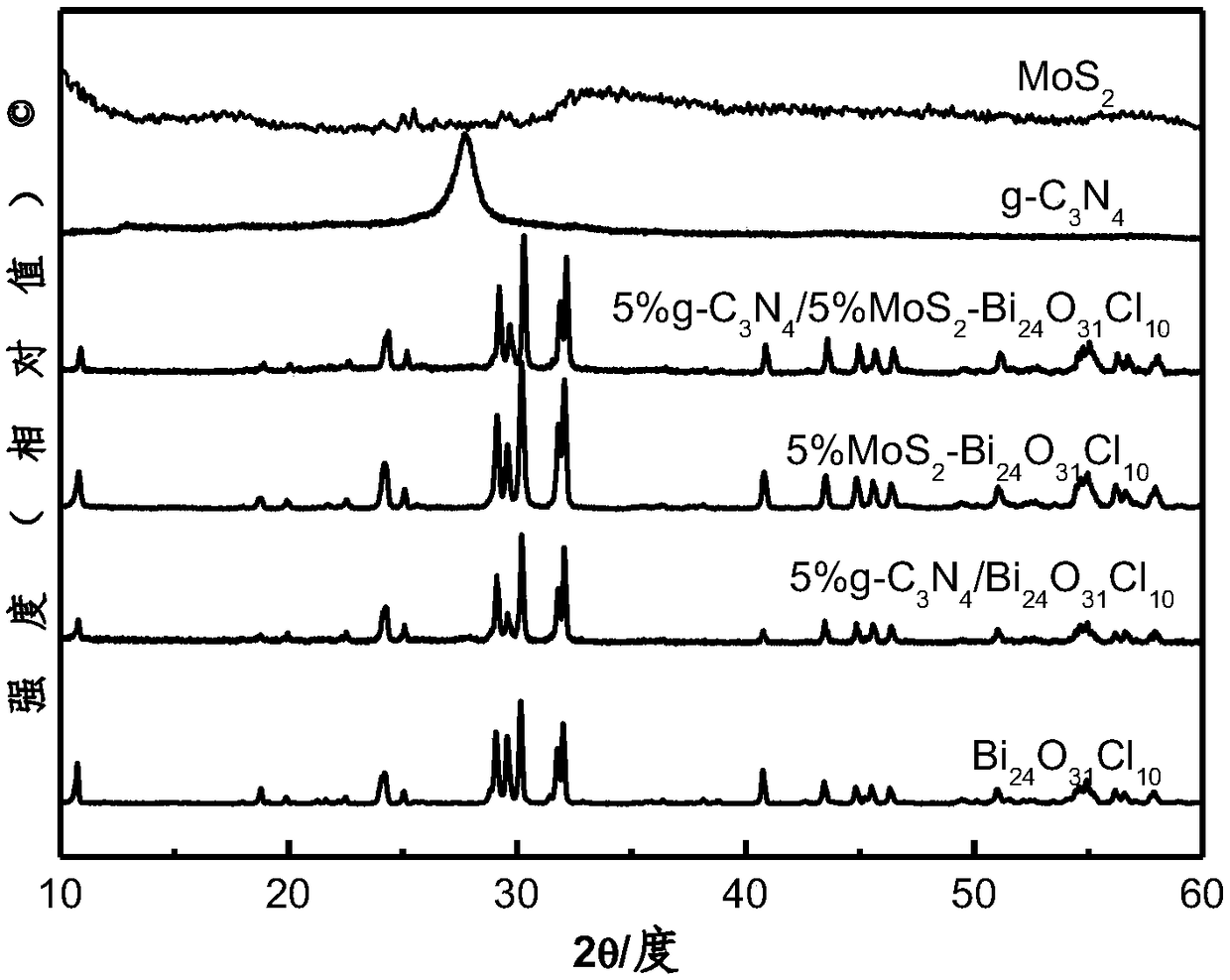

Preparation method of high-activity MoS2/g-C3N4/Bi24O31Cl10 composite photocatalyst

A g-c3n4, 5% g-c3n4 technology, applied in the fields of new materials, new energy utilization and environmental pollution control, can solve the problems of not meeting practical industrial applications, reducing the recombination rate of electrons and holes, and low photocatalytic activity. , to achieve the effect of improved photocatalytic efficiency, low cost and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

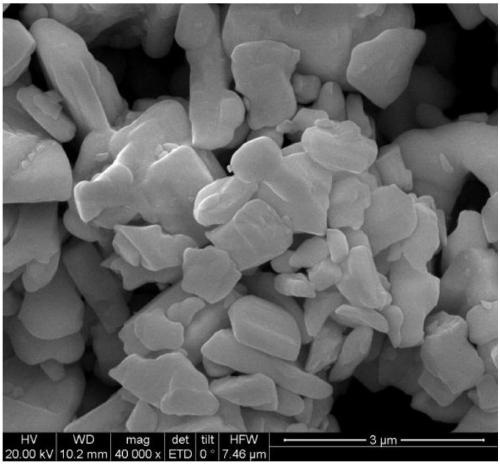

Embodiment 1

[0030] (1)Bi 24 O 31 Cl 10 Preparation: Dissolve 0.01mol of bismuth nitrate pentahydrate in 50ml of 10% dilute nitric acid by volume, then add 0.02mol of citric acid, and mix until completely dissolved; in addition, dissolve 0.01mol of ammonium chloride in 50ml of distilled water and mix Evenly until completely dissolved. Under the stirring of a constant temperature magnetic stirrer, slowly inject the ammonium chloride solution into the mixed solution of bismuth nitrate pentahydrate and dilute nitric acid of citric acid. When the solution is evenly mixed until the solution is in a clear state, adjust the pH value of the mixed solution to 6. Then continue to heat and stir at 60℃ for 4h, pour it into a crucible with a lid, and then calcinate in a horse boiling furnace at 600℃ for 3h to obtain a light yellow powder, which is pure Bi 24 O 31 Cl 10 .

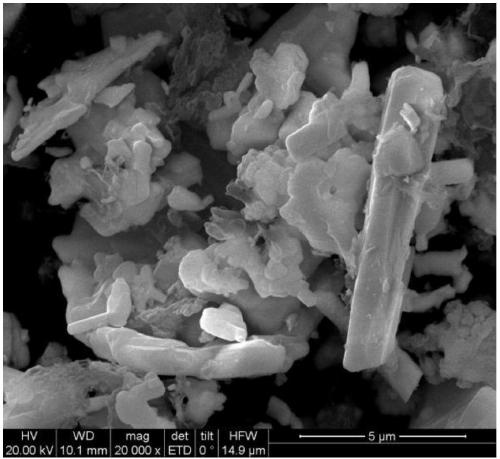

[0031] (2)g-C 3 N 4 Preparation: Mix 3g of melamine and 10ml of acetic acid (concentration of 36%) evenly, put it in a covered crucibl...

Embodiment 2

[0037] (1)Bi 24 O 31 Cl 10 Preparation: Dissolve 0.01mol of bismuth nitrate pentahydrate in 50ml of 10% dilute nitric acid by volume, then add 0.02mol of citric acid, and mix until completely dissolved; in addition, dissolve 0.01mol of ammonium chloride in 50ml of distilled water and mix Evenly until completely dissolved. Under a constant temperature magnetic stirrer, slowly inject the ammonium chloride solution into the mixed solution of bismuth nitrate pentahydrate and dilute nitric acid of citric acid. When the solution is uniformly mixed until the solution is in a clear state, adjust the pH value of the mixed solution to 5 with ammonia water. Then continue to heat and stir at 80℃ for 3h, pour it into a crucible with a lid, and then calcinate in a horse boiling furnace at 600℃ for 3h to obtain a light yellow powder, which is pure Bi 24 O 31 Cl 10 .

[0038] (2)g-C 3 N 4 Preparation: Mix 3g of melamine and 10ml of acetic acid (concentration of 36%) evenly, put it in a covered c...

Embodiment 3

[0044] (1)Bi 24 O 31 Cl 10 Preparation: Dissolve 0.01mol of bismuth nitrate pentahydrate in 50ml of 10% dilute nitric acid by volume, then add 0.02mol of citric acid, and mix until completely dissolved; in addition, dissolve 0.01mol of ammonium chloride in 50ml of distilled water and mix Evenly until completely dissolved. Under the stirring of a constant temperature magnetic stirrer, slowly inject the ammonium chloride solution into the mixed solution of bismuth nitrate pentahydrate and dilute nitric acid of citric acid. When the solution is evenly mixed until the solution is in a clear state, adjust the pH value of the mixed solution to 6. Then continue heating and stirring at 60°C for 3.5h, pour it into a crucible with a lid, and then calcinate in a horse boiling furnace at 600°C for 3h to obtain a light yellow powder, which is pure Bi 24 O 31 Cl 10 .

[0045] (2)g-C 3 N 4 Preparation: Mix 3g of melamine and 10ml of acetic acid (concentration of 36%) evenly, put it in a covered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com