Preparation method of CoTiO3/Bi4NbO8Cl composite photocatalyst material

A technology of catalyst and recombination of light, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of limited development of photogenerated carrier recombination efficiency, achieve low cost, high safety, The effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

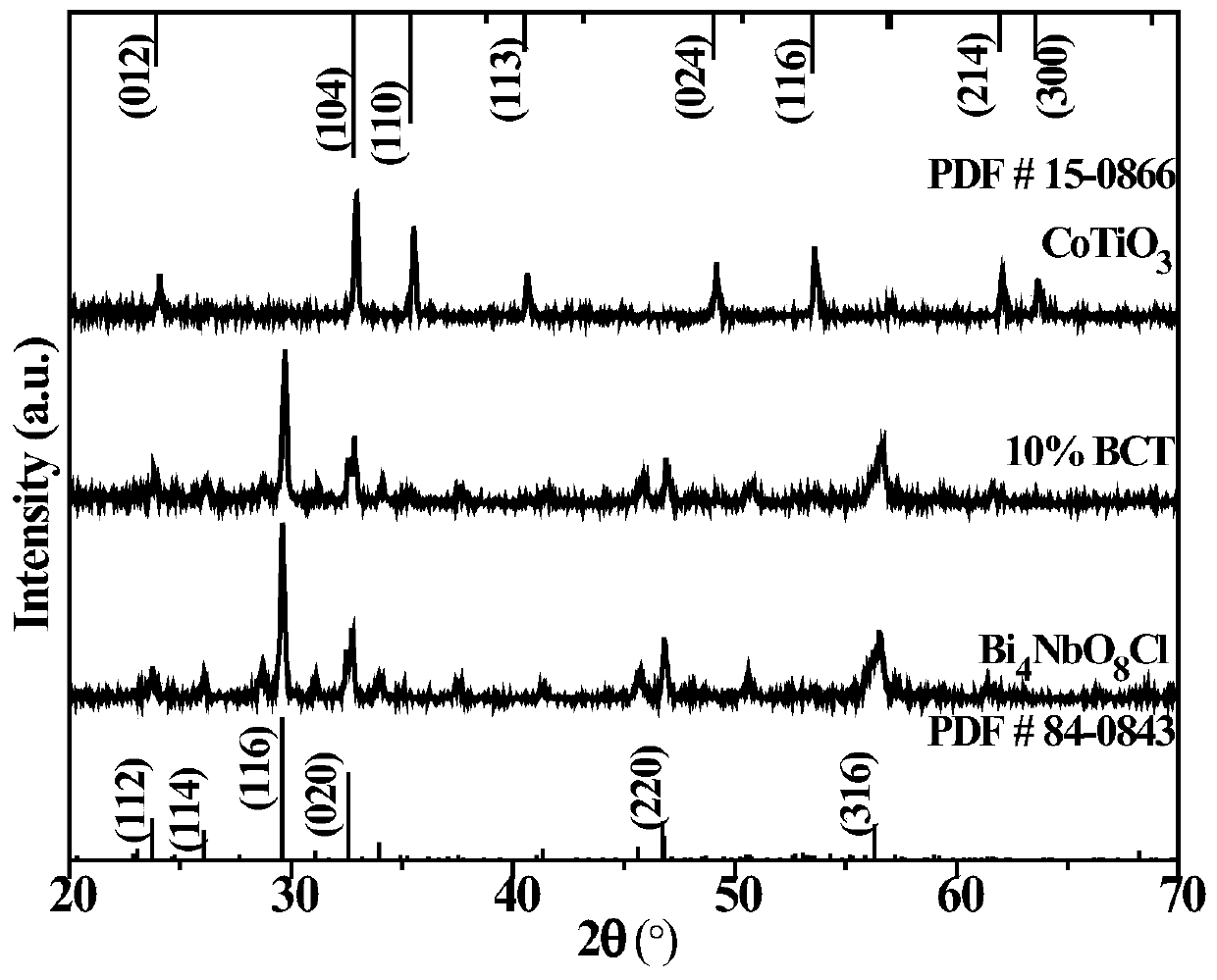

[0022] (1) Bi 4 NbO 8 Preparation of Cl: Dissolve 378.3mg of urea in 5mL of deionized water, and after fully stirring, add 135mg of niobium chloride, 727.6mg of bismuth nitrate pentahydrate and 130mg of bismuth oxychloride in turn, and ultrasonically stir for 30min respectively. The mixture was transferred to a porcelain boat, and put into a muffle furnace preheated to 600°C for calcination for 6h.

[0023] (2)CoTiO 3 Preparation: Dissolve 0.01 mol of cobalt acetate tetrahydrate and 0.01 mol of tetrabutyl titanate in 60 ml of ethylene glycol, and stir continuously for 5 hours at room temperature to make them fully react. Then it was centrifuged and washed three times with ethanol, dried in an oven at 60 °C for 6 h, then transferred to a muffle furnace, calcined at 700 °C for 4 h in an air atmosphere, and the heating rate was 5 °C / min, and ground to obtain CoTiO 3 powder.

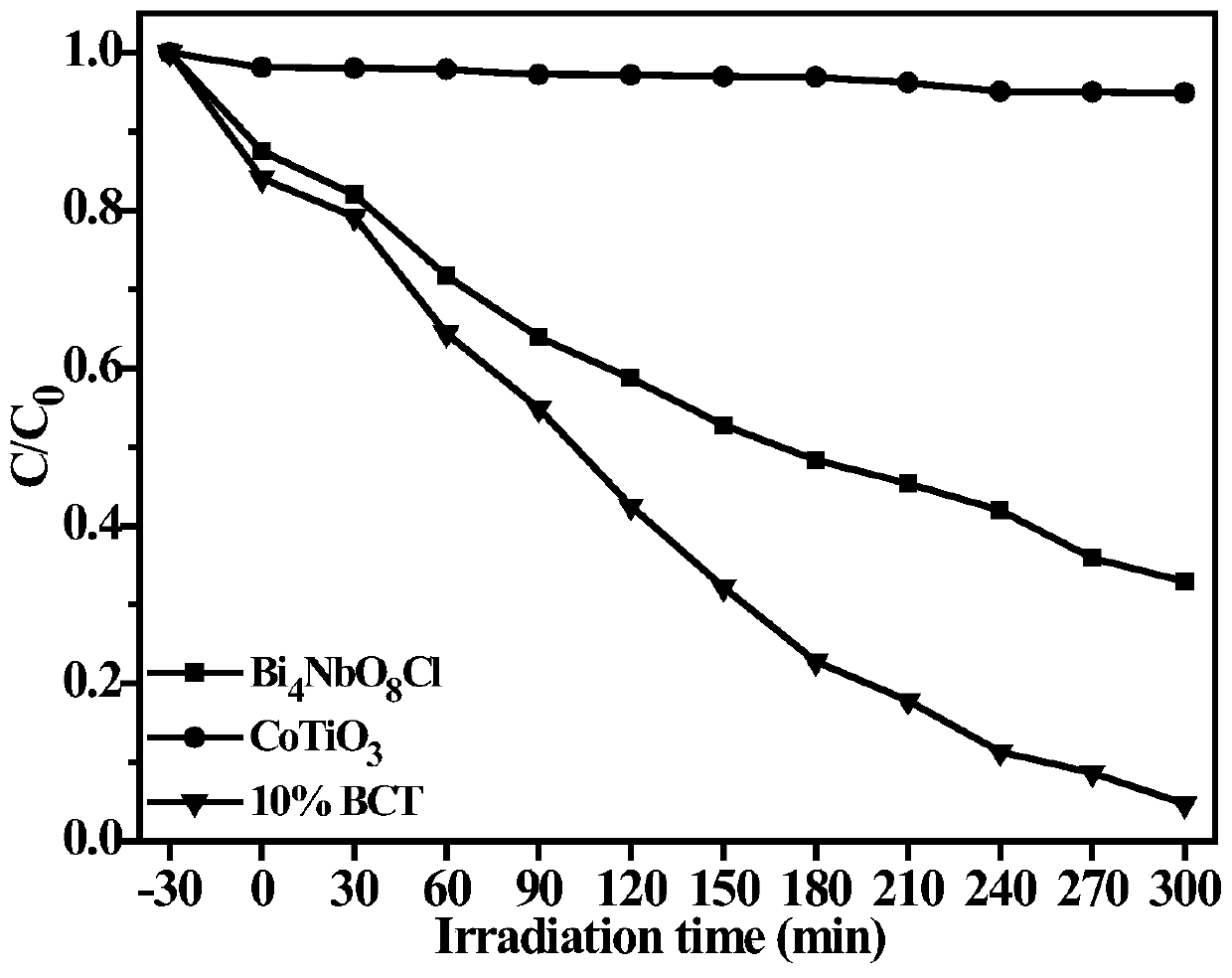

[0024] (3)CoTiO 3 / Bi 4 NbO 8 Preparation of Cl complex: weigh 0.4g Bi 4 NbO 8 Cl and 0.04g CoTi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com