Preparation method and application of spherical tantalum pentoxide

A tantalum pentoxide, spherical technology, applied in the field of photocatalytic materials, can solve the problems of waste liquid discharge, long preparation cycle, cumbersome operation steps, etc., and achieve the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

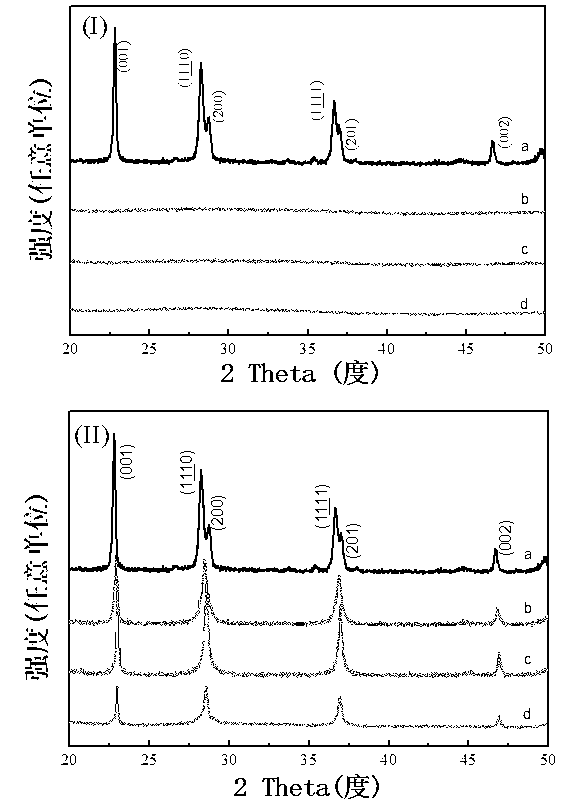

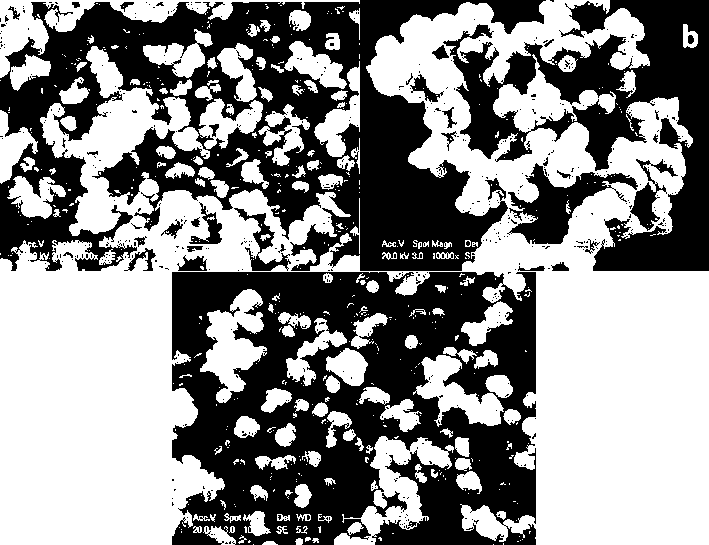

[0020] Measure 36.3mL of absolute ethanol into a 150mL beaker (evaporating dish), then add 3.63mL of tantalum ethoxide (the volume ratio of absolute ethanol / tantalum ethoxide is 10:1, the total volume of the solution is 40 mL), and stir the solution until it becomes transparent . Ignite it with a match, the liquid starts to burn from the liquid surface, and a white sample is obtained after burning. Determine the XRD of the sample and find that the obtained sample is amorphous Ta 2 o 5 ( figure 2 (I), curve c). The resulting amorphous Ta 2 o 5 Place it in a muffle furnace for high temperature annealing at 800°C for 3 hours, measure the XRD of the sample, and find that the obtained Ta 2 o 5 The sample presents a good crystal form ( figure 2 (II), curve c). Determination of the SEM surface morphology of the sample, it can be found that the Ta 2 o 5 for microspheres ( image 3 (a)). Ta 2 o 5 The UV-Vis diffuse reflectance spectrum test shows that the Ta 2 o 5 Ha...

Embodiment 2

[0024] Measure 33.3 mL of absolute ethanol into a 150 mL beaker, then add 6.6 mL of tantalum ethoxide (the volume ratio of absolute ethanol / tantalum ethoxide is 5:1, the total volume of the solution is 40 mL), and stir the solution until it becomes transparent. When lit with a match, the liquid starts to burn from the liquid surface. During the burning process, water is continuously generated, and the generated water promotes the hydrolysis of tantalum ethoxide to form Ta 2 o 5 , a white sample was obtained after combustion. Determination of the XRD of the sample ( figure 2 (I) Curve b), the obtained sample was found to be amorphous Ta 2 o 5 . The resulting amorphous Ta 2 o 5 Place it in a muffle furnace for high temperature annealing at 800°C for 3 hours, measure the XRD of the sample, and find that the obtained Ta 2 o 5 The sample presents a good crystal form ( figure 2 (II), curve b). Measure the SEM surface morphology of the sample and find that the Ta obtained...

Embodiment 3

[0026] Measure 37.5 mL of absolute ethanol into a 150 mL beaker, then add 2.5 mL of tantalum ethoxide (the volume ratio of absolute ethanol / tantalum ethoxide is 15:1, the total volume of the solution is 40 mL), and stir the solution until it becomes transparent. When lit with a match, the liquid starts to burn from the liquid surface. During the burning process, water is continuously generated, and the generated water promotes the hydrolysis of tantalum ethoxide to form Ta 2 o 5 , a white sample was obtained after combustion. Determination of the XRD of the sample ( figure 2 (I), curve d ), it can be found that the obtained sample is amorphous Ta 2 o 5 . The resulting amorphous Ta 2 o 5 Place it in a muffle furnace for high temperature annealing at 800°C for 3 hours, measure the XRD of the sample, and find that the obtained Ta 2 o 5 The sample presents a good crystal form ( figure 2 (II), curve d). Determination of the SEM surface morphology of the sample, it can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com