High-entropy oxide lithium ion battery negative electrode material with high conductivity and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., to achieve the effect of improving conductivity and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

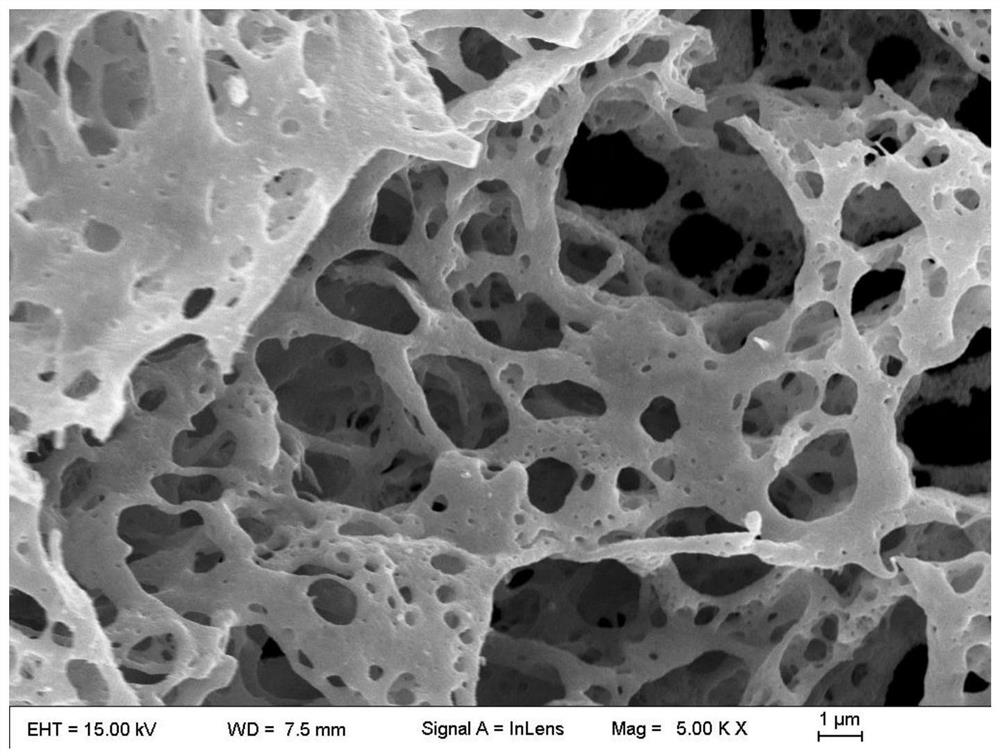

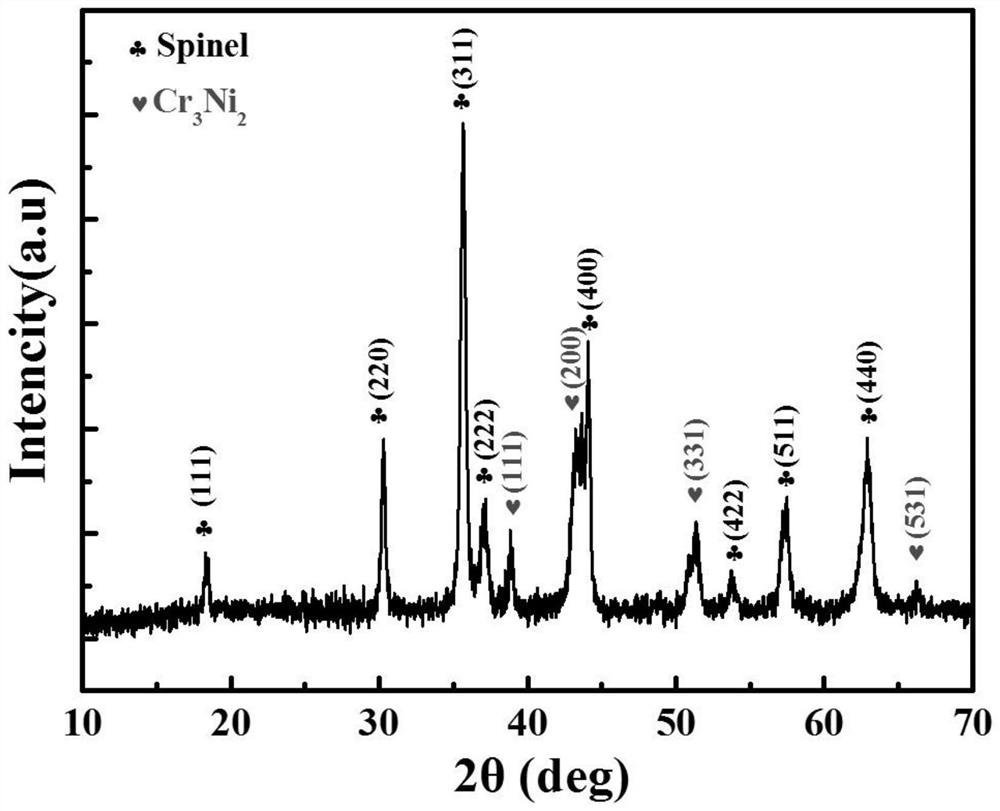

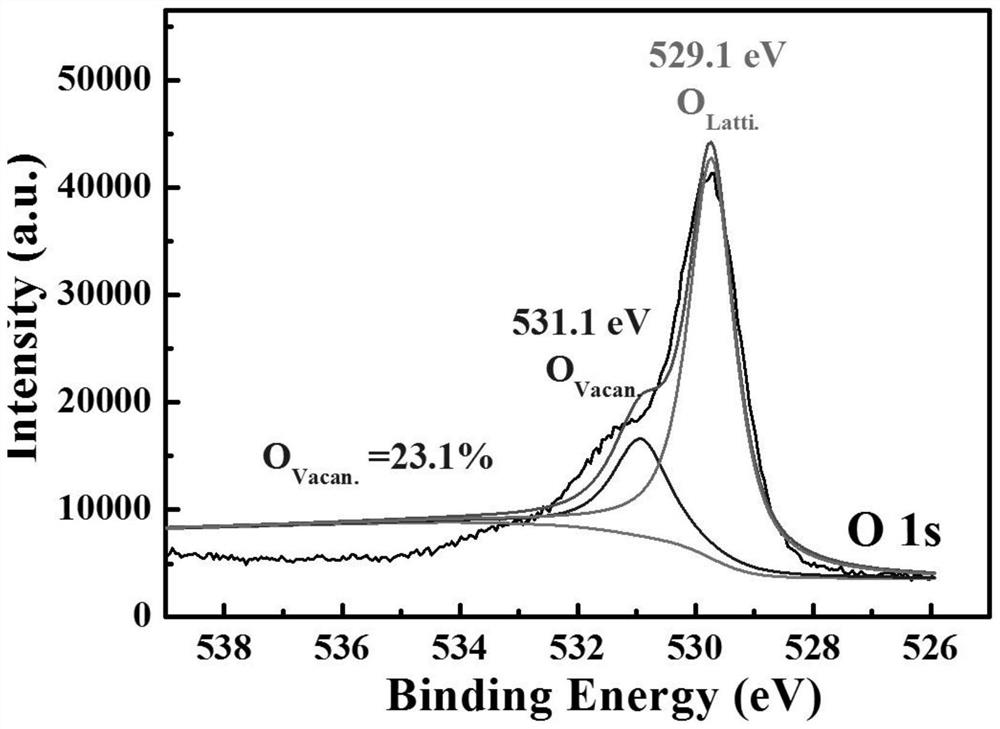

[0031]A spine-type high entropy oxide lithium ion negative electrode material having high conductivity, molecular formula (CoCrcufeni)3 / 5O4-δ : Weigh the equimolar amount of metal nitrate, specifically 5.821 g of CO (NO3)2· 6h2O, 8.003G CR (NO3)3· 9h2O, 4.832G Cu (NO3)2· 3h2O, 8.080g Fe (NO3)3· 9h2O and 5.816G Ni (NO3)2· 6h2O Soluble in 10 ml of distilled water, stirred and uniformly gave a mixed solution of the metal salt; then weighted 0.150 g of glycine to add a mixed solution, and the magnetic force was stirred for 1 h after drying to obtain a gel at 60 ° C, and the gel was placed in gold. 500 ° C in the furnace furnace reaction for 20 min, resulting in a porous structure, 23.1% oxygen space and a small amount of Cr3Ni2Cocrcufeni3 / 5O4-δ High entropy oxide powder material, the XRD, SEM and O1S of the powder material, such asfigure 1 ,figure 2 Repeated with Figure 3.

[0032]As the active substance, SuperP carbon black is a conductive agent, and the polyvinylidene fluoride (PVDF) is ...

Embodiment 2

[0035]A spine-type high entropy oxide lithium ion negative electrode material having high conductivity, molecular formula (CoCrcufeni)3 / 5O4-δ : Weigh the equimolar amount of metal nitrate, specifically 5.821 g of CO (NO3)2· 6h2O, 8.003G CR (NO3)3· 9h2O, 4.832G Cu (NO3)2· 3h2O, 8.080g Fe (NO3)3· 9h2O and 5.816G Ni (NO3)2· 6h2O Soluble in 20 ml of distilled water, stir well to obtain a mixed solution of a metal salt; then 0.300 g of urea is added to the mixed solution, and the magnetic force is stirred at 80 ° C to dry the gel, and then placed in the gel The gold furnace Muff furnace is 50 min to obtain a porous structure, 16.2% oxygen space and a small amount of Cr.3Ni2Cocrcufeni3 / 5O4-δ High entropy oxide powder material.

[0036]As the active substance, Super P carbon black is a conductive agent, and the polyvinylidene fluoride (PVDF) is a binder (mass ratio of 7: 2: 1), which is dissolved in N-methylpyrrolidone after being uniform. The electrode sheet is applied to the neat copper foi...

Embodiment 3

[0039]A spine-type high entropy oxide lithium ion negative electrode material having high conductivity, molecular formula (CoCrcufeni)3 / 5O4-δ : Weigh the equimolar amount of metal nitrate, specifically 5.821 g of CO (NO3)2· 6h2O, 8.003G CR (NO3)3· 9h2O, 4.832G Cu (NO3)2· 3h2O, 8.080g Fe (NO3)3· 9h2O and 5.816G Ni (NO3)2· 6h2O Soluble in 15 ml of distilled water, stir well to obtain a mixed solution of the metal salt; then weighted 0.231 g of ammonium acetate to add a mixed solution, and the magnetic force was stirred at 80 ° C to obtain a gel, and the gel is placed. The reaction was 50 min at 800 ° C in the golden furnace Master furnace to obtain a porous structure, 20.6% oxygen space and a small amount of Cr.3Ni2Cocrcufeni3 / 5O4-δ High entropy oxide powder material.

[0040]As the active substance, SuperP carbon black is a conductive agent, and the polyvinylidene fluoride (PVDF) is a binder (mass ratio of 7: 2: 1), and is dissolved in N-methylpyrrolidone to make a slurry uniformly. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com