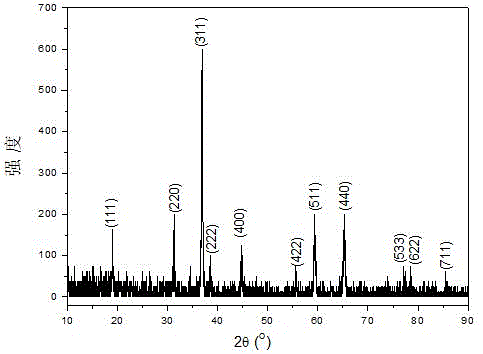

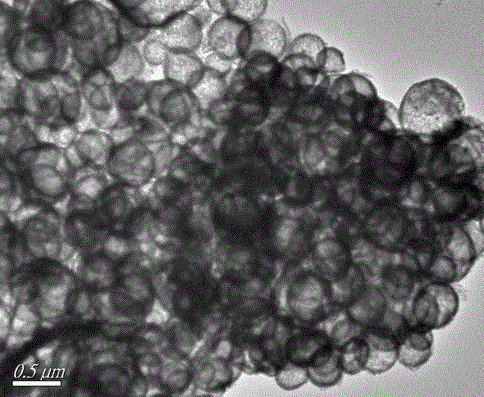

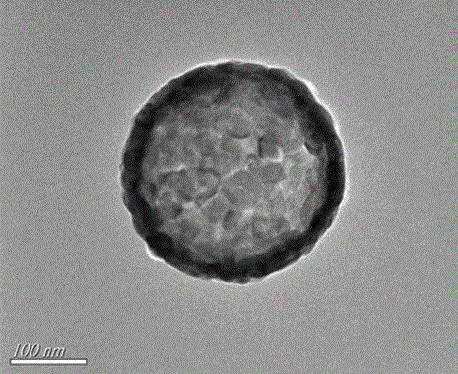

Method for producing nanometer structure cobalt tetroxide sub-micron hollow balls

A sub-nanostructure technology of cobalt tetroxide, which is applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems of no hollow spheres of cobalt tetroxide, etc., and achieve the effects of uniform size, simple synthesis equipment, and shortened process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 1.748 g cobalt nitrate hydrate [Co(NO 3 ) 2 ·6H 2 O] and 0.5 g glycine, put in a beaker, add appropriate amount of distilled water, ultrasonically dissolve, mix evenly, add distilled water to make the volume to 100 ml, obtain a mixed solution with a cobalt ion concentration of 0.06 mol / L, put it into an ultrasonic atomization device In the experiment, the air flow rate was set at 0.5 L / min, and the atomization device with piezoelectric ceramic sheet frequency at 2.4 MHz was turned on, and the atomized droplets generated were loaded into the tube furnace with a temperature of 800 °C by the air (the temperature of the tube furnace was In a quartz tube with an inner diameter of 16 mm and an outer diameter of 20 mm), heating triggers a combustion reaction, and the resulting solid product is collected by a bag collection device to obtain the final product.

Embodiment 2

[0026] Weigh 1.748 g cobalt nitrate hydrate [Co(NO 3 ) 2 ·6H 2 O] and 0.45 g glycine were placed in a beaker, an appropriate amount of distilled water was added, ultrasonically dissolved, mixed evenly, and distilled water was added to make the volume to 100 ml to obtain a mixed solution with a cobalt ion concentration of 0.06 mol / L, which was put into an ultrasonic atomization device In the experiment, the air flow rate was set at 0.6 L / min, and the atomization device with piezoelectric ceramic sheet frequency at 2.4 MHz was turned on, and the atomized droplets generated were loaded into the tube furnace with a temperature of 800 °C by the air (the In a quartz tube with an inner diameter of 16 mm and an outer diameter of 20 mm), heating triggers a combustion reaction, and the resulting solid product is collected by a bag collection device to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com