High-activity and high-stability supported nanometer gold catalyst, preparation and application method

A catalyst and supported technology, applied in the field of preparation and supported nano-gold catalysts, can solve the problems of insufficient low-temperature catalytic activity, insufficient catalyst stability, poor water vapor resistance, etc. The effect of good change, storage and reaction stability, and high metal dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

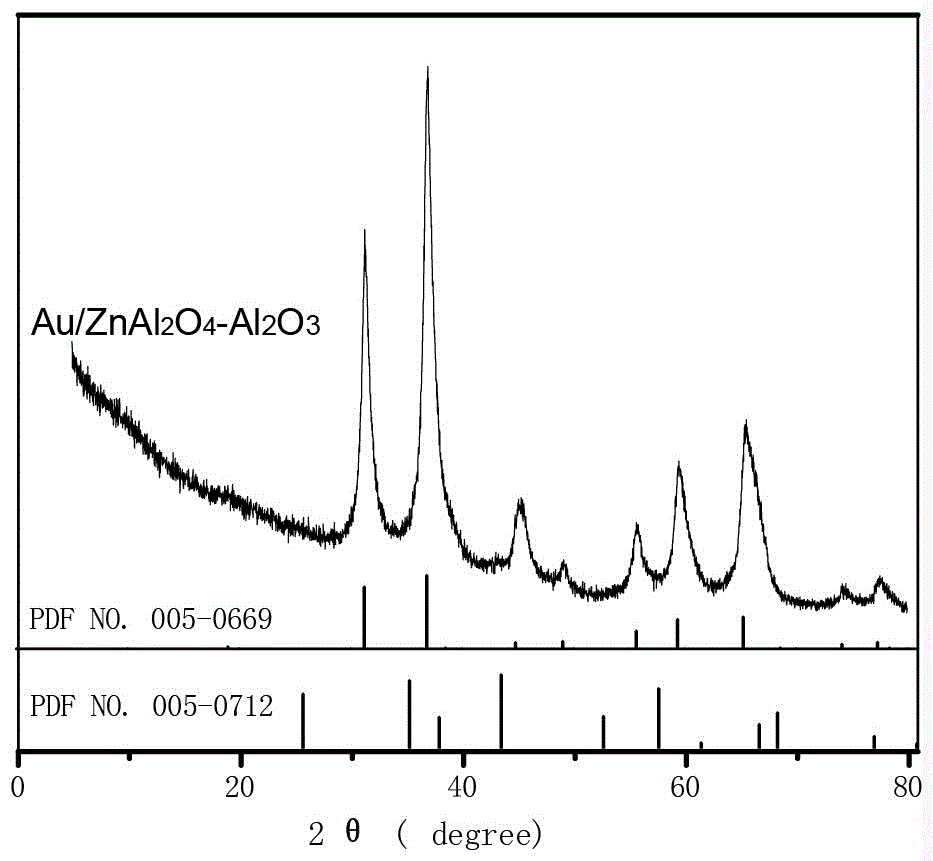

Embodiment 1

[0026] 1. 10 wt.%ZnAl 2 o 4 -TiO 2 Preparation of:

[0027] Impregnation method: Weigh 3.4430g Zn(NO 3 ) 2 solution (33.44 wt.%) and 10.3944g Al(NO 3 ) 3 solution (24.85wt.%), mix, pour 10g TiO 2 Carrier (anatase type), shake quickly and evenly, impregnate, stand and age, and then in 100 o C drying 8 h, after 1000 o C roasted for 6 h to get ZnAl 2 o 4 / TiO 2 Composite carrier;

[0028] Solution combustion method: measure 1.8544g Zn(NO 3 ) 2 solution (33.44 wt.%) and 5.6136g Al(NO 3 ) 3 solution (24.85 wt.%), add 4.8ml of distilled water, then add 1.9655g of urea, and pour 5g of TiO 2 Carrier (anatase type), mix well and heat in a microwave oven or muffle furnace until the solution burns, then at 800 o C roasted for 6 h, ZnAl was also obtained 2 o 4 / TiO 2 Composite carrier.

[0029] 2. 1%Au / 10 wt.%ZnAl 2 o 4 -TiO 2 Preparation of:

[0030] Anion impregnation method: measure chloroauric acid solution (9.56g Au / L) 10.6 mL, drop Na 2 CO 3 solution unt...

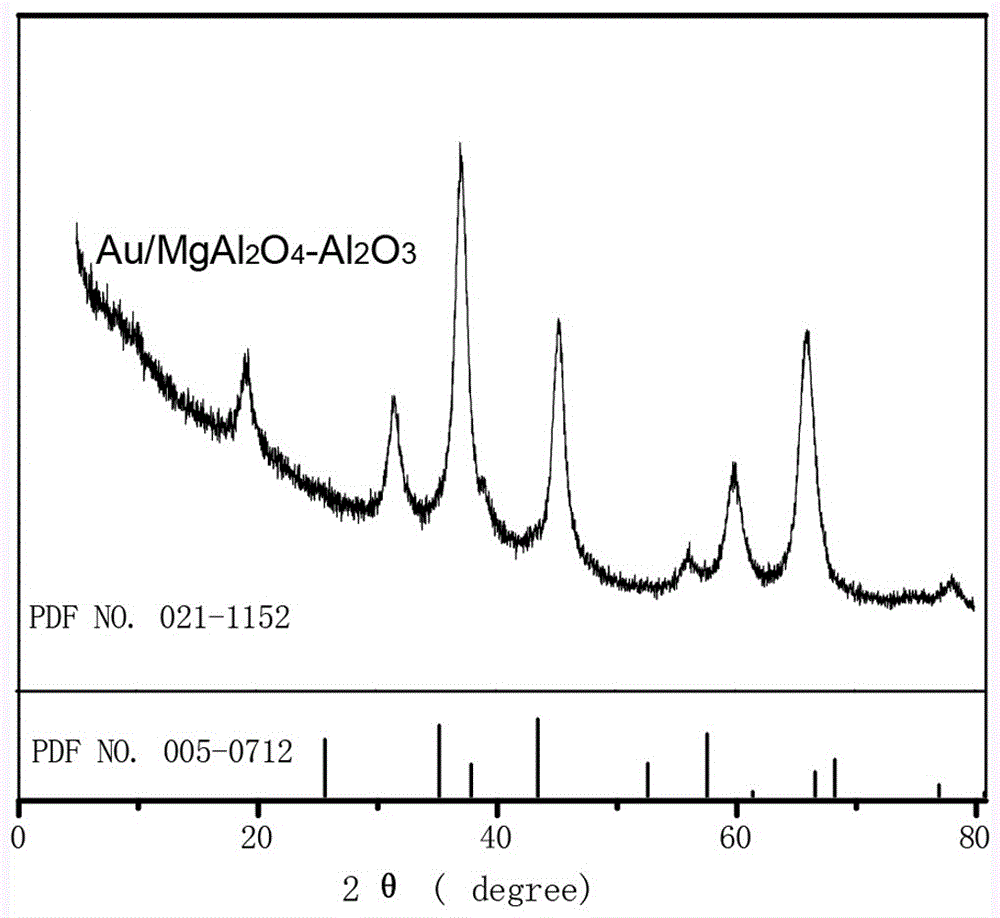

Embodiment 2

[0035] 1. 10 wt.%MgAl 2 o 4 -TiO 2 Preparation of:

[0036] Impregnation method: Weigh 2.7703g Mg(NO 3 ) 2 solution (41.80 wt.%) and 13.3803g Al(NO 3 ) 3 solution (24.85wt.%), mix, pour 10g TiO 2 Carrier (P25), shake quickly evenly, impregnate, stand and age, and then in 100 o C drying 6h, after 700 o C roasted for 6 h to obtain MgAl 2 o 4 -TiO 2 Composite carrier;

[0037] Solution combustion method: Weigh 1.4965g Mg(NO 3 ) 2 solution (41.80 wt.%) and 7.2341g Al(NO 3 ) 3 Solution (24.85 wt.%), mix, add 7.0ml distilled water, then add 2.5329g urea, pour 5g TiO 2 Carrier (P25), after mixing evenly, heat in a microwave oven or muffle furnace until the solution burns, after 700 o C roasting for 4 h also yielded MgAl 2 o 4 -TiO 2 Composite carrier.

[0038] 2. 1%Au / 10 wt.%MgAl 2 o 4 -TiO 2 Preparation of:

[0039]Anion impregnation method: Measure 5.3ml of chloroauric acid solution (19.13g / L), add KOH solution dropwise until the pH value of the solution is...

Embodiment 3

[0044] 1. 10 wt.%NiAl 2 o 4 -TiO 2 Preparation of:

[0045] Immersion method: Weigh 5.0532g Ni(NO 3 ) 2 solution (22.73 wt.%) and 10.7785g Al(NO 3 ) 3 solution (24.85wt.%), mix, pour 10g TiO 2 Carrier (rutile type), let it stand for 6 h, then at 150 o C dried for 2 h, after 900 o C roasted for 8 h to obtain NiAl 2 o 4 -TiO 2 Composite carrier

[0046] Solution combustion method: Weigh 2.7302g Ni(NO 3 ) 2 solution (22.73 wt.%) and 5.8302g Al(NO 3 ) 3 solution (24.85 wt.%), mix, add 4.1ml distilled water, then add 2.0400g urea, pour 5g TiO 2 Carrier (rutile type), mix well and heat in a microwave oven or muffle furnace until the solution burns, after 800 o C roasting for 6h also yields NiAl 2 o 4 -TiO 2 Composite carrier.

[0047] 2. 1%Au / 10 wt.%NiAl 2 o 4 -TiO 2 Preparation of:

[0048] Anion impregnation method: Measure 5.3ml of chloroauric acid solution (19.13g / L), add Na 2 CO 3 solution until the solution pH value is 5, 10g NiAl 2 o 4 -TiO 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com