Preparation method of high specific surface area ZnMn2O4

A high specific surface area, silica technology, applied in nanotechnology for materials and surface science, chemical instruments and methods, manganate/permanganate, etc., can solve the small specific surface area of nanomaterials, preparation conditions Harsh and other problems, to achieve the effect of easy mass production, short production cycle, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

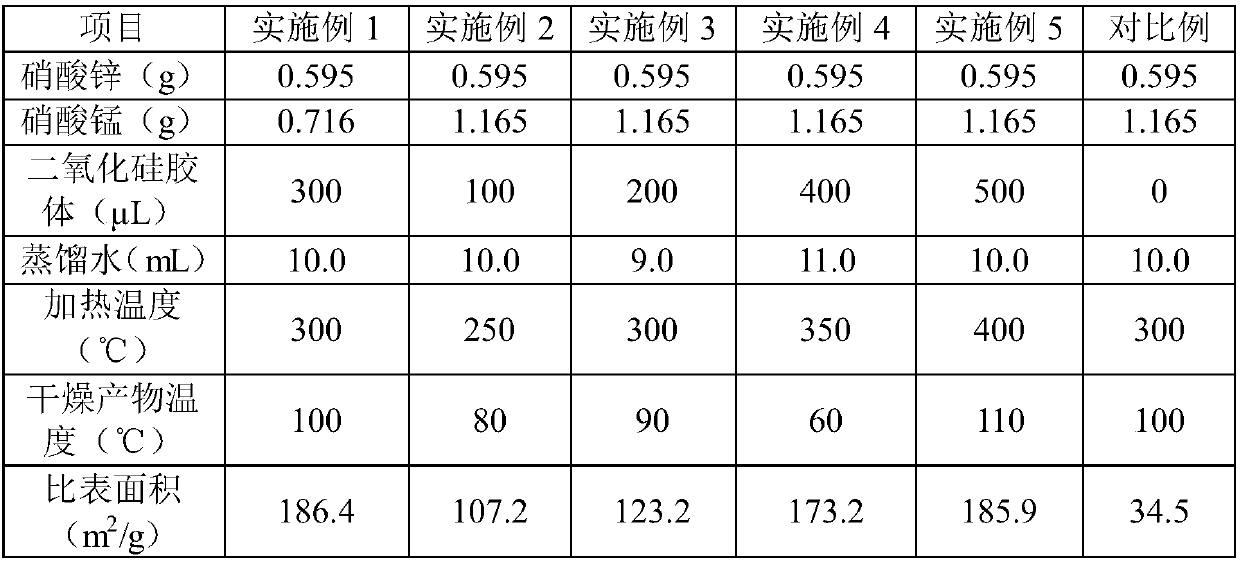

[0018] In a 100ml beaker, dissolve zinc nitrate and manganese nitrate in water, then add glycine, stir to dissolve and add SiO 2 Colloidal solution (not added in the comparative example), after ultrasonic dispersion for 10 minutes, heat the beaker to a specific temperature until the solution in the beaker undergoes a combustion reaction. After the reaction is completed, wash the product with distilled water, and then use sodium hydroxide solution at 80°C Etch the solid product for 24h to remove SiO 2 , followed by washing the isolated product with distilled water and ethanol, and finally drying at a specific drying temperature to obtain ZnMn 2 o 4 powder. The results of measuring the specific surface area with the specific surface area analyzer of Quantachrome Company are shown in the table below.

[0019]

[0020] As can be seen from Table 1, in the comparative example, due to not adding silica colloid, the ZnMn of its final gained 2 o 4 The specific surface area of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com