Preparation method for ZnO two-dimensional porous material

A technology of porous materials and porous powders, which is applied in the field of preparation of ZnO two-dimensional porous materials, can solve problems such as tedious methods, unsuitable for large-scale industrial production, harsh conditions, etc., and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1.250 g of zinc nitrate Zn(NO 3 ) 2 ?6H 2 O and 1.750 g of glycine C 2 h 5 NO 2 Completely dissolved in 15 mL of distilled water to obtain a mixed solution, and then the crucible containing the above solution was placed in a muffle furnace and heated at 400 °C. The solution undergoes boiling, foaming, drying, and self-propagating combustion to obtain a fluffy foam-like substance, which can be further heat-treated at 500 °C for 5 hours to obtain a ZnO two-dimensional porous material.

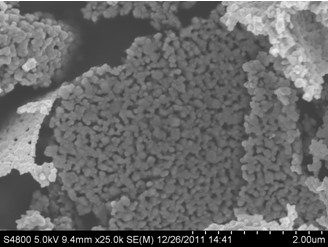

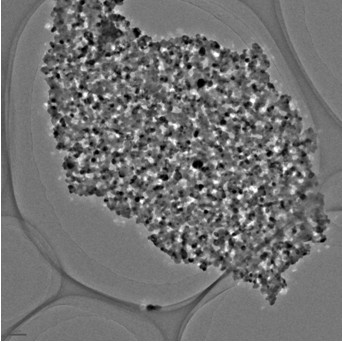

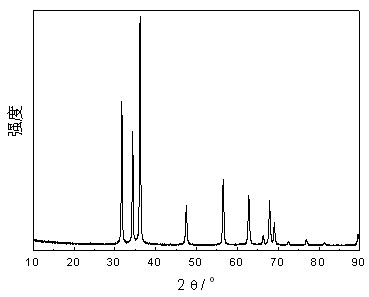

[0019] figure 1 and figure 2 They are field emission scanning electron micrographs and transmission electron micrographs of the obtained product, respectively. It can be seen that the product has a porous micron-scale two-dimensional structure, and the pore size is relatively uniform. image 3 It is the X-ray diffraction pattern of the product, and it can be seen that the phase of the obtained product is ZnO through comparison with the standard card.

Embodiment 2

[0021] 0.500 g of Zn(NO 3 ) 2 ?6H 2 O and 1.750 g of C 2 h 5 NO 2 Completely dissolved in 15 mL of distilled water to obtain a mixed solution, and then the crucible containing the above solution was placed in a muffle furnace and heated at 400 °C. The solution undergoes boiling, foaming, drying, and self-propagating combustion to obtain a fluffy foam-like substance, which can be further heat-treated at 500 °C for 5 hours to obtain a ZnO two-dimensional porous material.

[0022] Figure 4 It is a field emission scanning electron micrograph of the product, and it can be seen that the product is a porous two-dimensional structure with high porosity.

Embodiment 3

[0024] 0.875 g of Zn(NO 3 ) 2 ?6H 2 O and 1.750 g of C 2 h 5 NO 2 Completely dissolved in 15 mL of distilled water to obtain a mixed solution, and then the crucible containing the above solution was placed in a muffle furnace and heated at 500 °C. The solution undergoes boiling, foaming, drying, and self-propagating combustion to obtain a fluffy foam-like substance, which can be further heat-treated at 500 °C for 5 hours to obtain a ZnO two-dimensional porous material.

[0025] Figure 5 and Figure 6 The low-magnification and high-magnification field emission scanning electron micrographs of the product are respectively, and it can be seen that the product has a porous two-dimensional structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com