RGO/Cu composite material and preparation method thereof

A composite material and suspension technology, which is applied in the field of rGO/Cu composite material and its preparation, can solve the problems of high GO content, difficult to distribute uniformly, and small specific surface area of micron commercial copper powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, the preparation method of rGO / Cu composite material is as follows:

[0035] Preparation of porous flaky cuprous oxide: first dissolve copper nitrate and glucose in 50ml deionized water at a mass ratio of 10:3, and ultrasonicate for 15 minutes to obtain a uniform mixed solution; then pour the mixed solution into a corundum crucible with a specification of 500ml Heating with a small stove in the air, the aqueous solution undergoes boiling, foaming and burning, and finally forms a porous sponge-like powder.

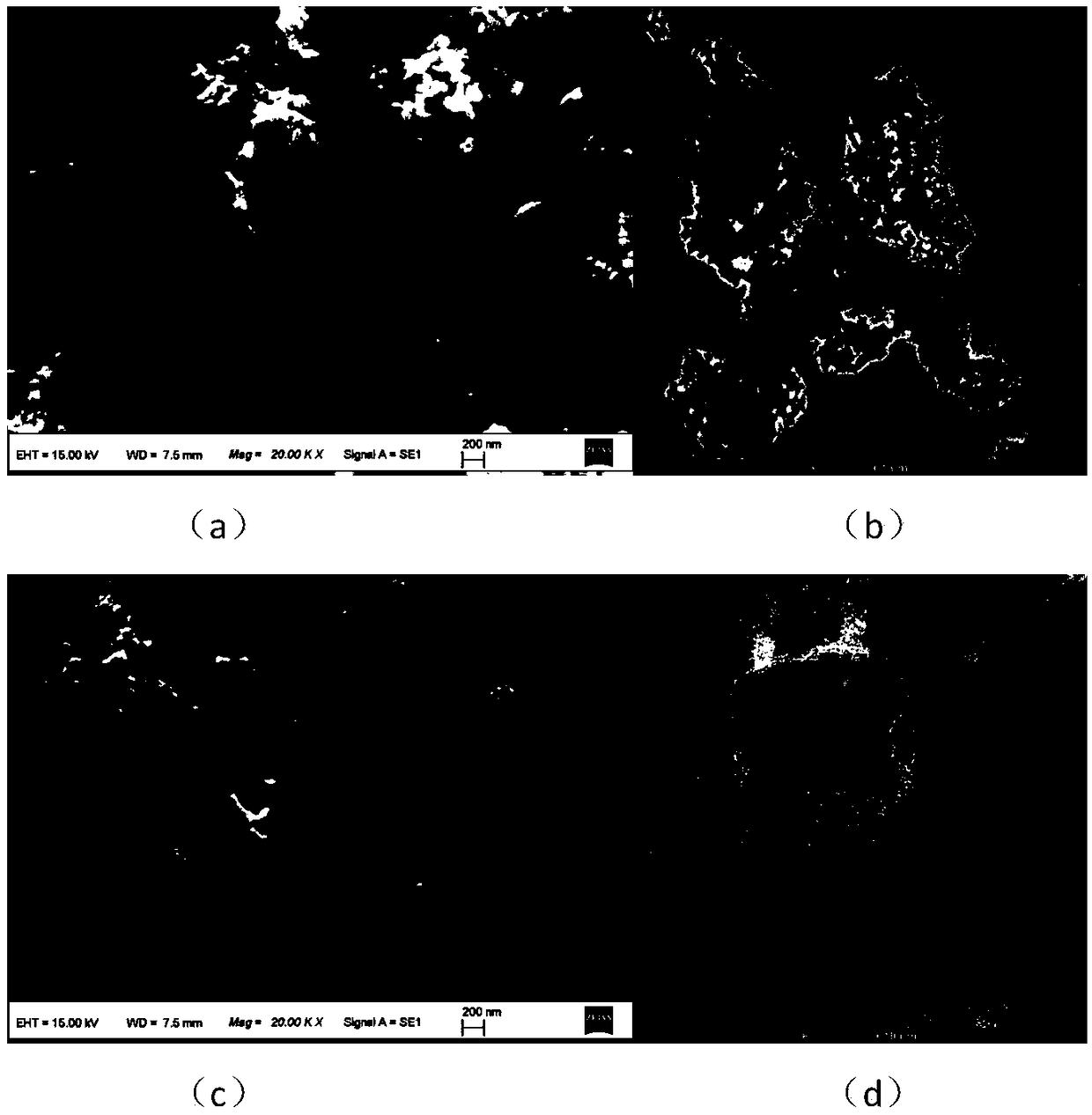

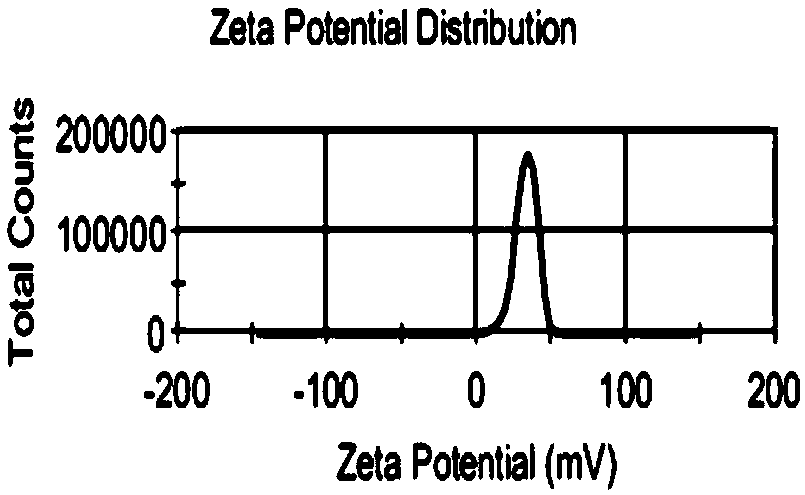

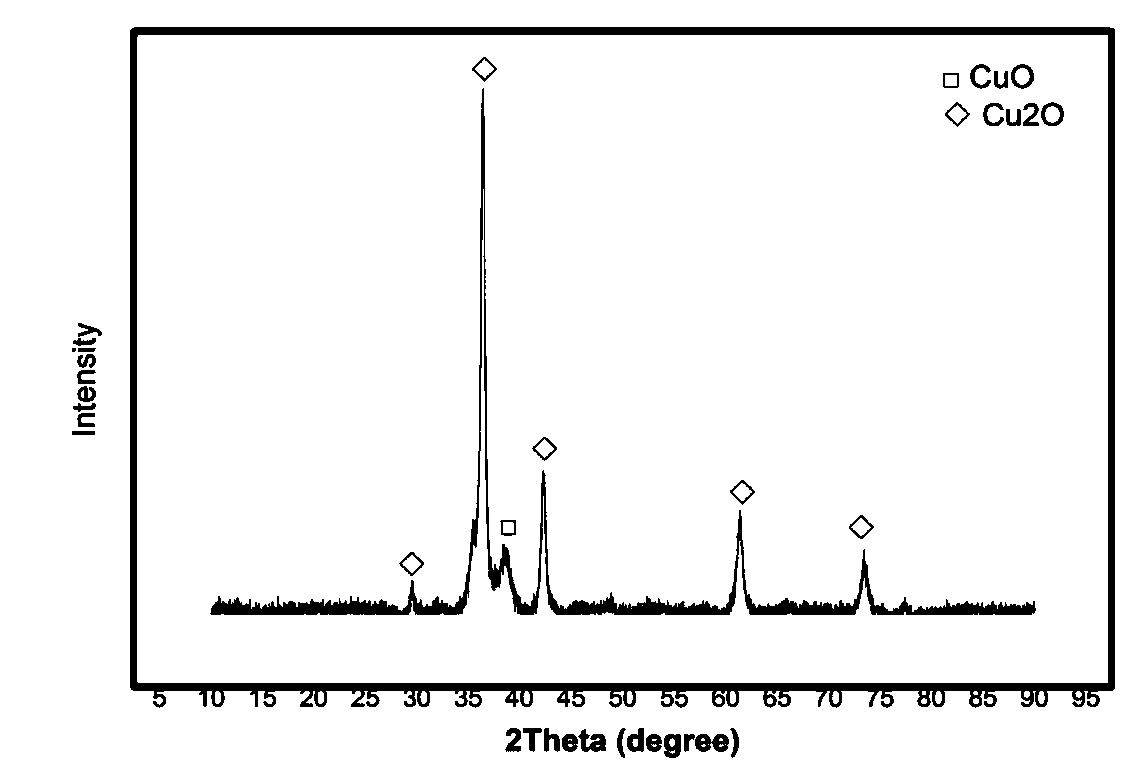

[0036] Preparation of rGO / Cu composite material: graphene oxide has a thickness of 3.4-7nm, 6-10 layers, a diameter of 10-50 microns, and a specific surface area of 100-300 square meters per gram. The prepared porous flaky cuprous oxide and graphene oxide were dispersed in water by ultrasonic for 30 minutes respectively to obtain cuprous oxide suspension (0.1 g / ml) and graphene oxide colloidal suspension (0.001 g / ml); then The graphene oxide col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com