Preparation method of cobalt oxide/graphene composite nano material

A compound technology of cobalt tetraoxide and graphene, which is applied in the field of materials, can solve the problems of difficult solid-liquid separation, many synthesis steps, and long time, and achieve the effect of simple synthesis equipment, simple process flow, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

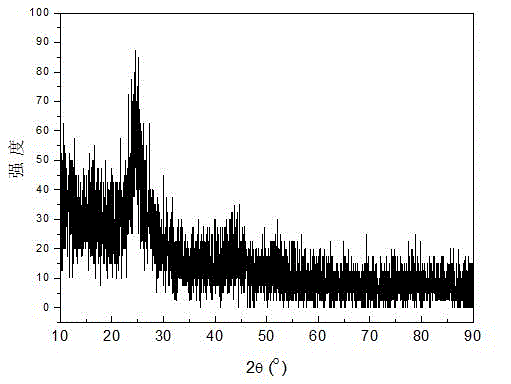

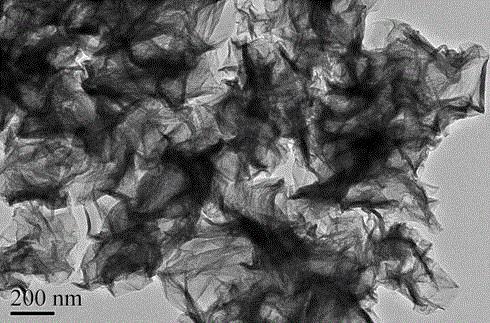

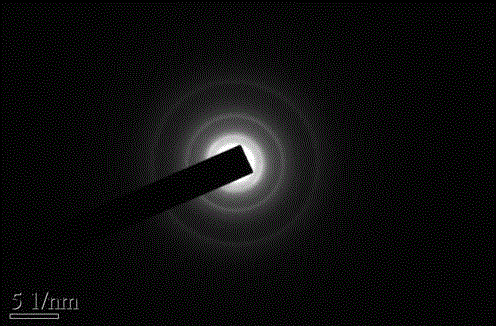

Image

Examples

Embodiment 1

[0033] Weigh 30 mg of glycine, add 8 ml of cobalt nitrate solution with a concentration of 0.06 mol / L, mix evenly by ultrasonic, add 100 ml of 0.5 mg / ml graphene oxide suspension dropwise, mix evenly by ultrasonic, put the mixture into In the ultrasonic atomization device with circulating cooling, set the nitrogen flow rate to 0.8 L / min, and turn on the atomization device with a piezoelectric ceramic plate frequency of 2.4 MHz. The solid product generated by the combustion reaction was collected by depositing a single crystal silicon wafer placed at the outlet end of the tube furnace.

Embodiment 2

[0035] Weigh 60 mg of glycine, add 15 ml of cobalt nitrate solution with a concentration of 0.06 mol / L, mix evenly by ultrasonic, add 100 ml of 0.5 mg / ml graphene oxide suspension dropwise, mix evenly by ultrasonic, put the mixture into In the ultrasonic atomization device with circulating cooling, set the nitrogen flow rate to 0.8 L / min, and turn on the atomization device with a piezoelectric ceramic plate frequency of 2.4 MHz. The solid product generated by the combustion reaction was collected by depositing a single crystal silicon wafer placed at the outlet end of the tube furnace.

Embodiment 3

[0037] Weigh 115 mg of ethylene glycol, add 25 ml of cobalt nitrate solution with a concentration of 0.06 mol / L, mix evenly by ultrasonic, add 100 ml of 0.5 mg / ml graphene oxide suspension dropwise, mix evenly by ultrasonic, and put the mixed solution into Into the ultrasonic atomization device with circulating cooling, set the nitrogen flow rate to 0.8 L / min, turn on the atomization device with a piezoelectric ceramic sheet frequency of 2.4 MHz, and the generated droplets are loaded into the furnace tube at 800 °C by nitrogen gas, causing The solid product generated by the combustion reaction of the solution is deposited on a single crystal silicon wafer placed at the outlet end of the tube furnace to collect samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com