Method for preparing rare earth perovskite/biochar composite material from forestry and agricultural residues and application of rare earth perovskite/biochar composite material

A technology of agricultural and forestry waste and composite materials, which is applied in the field of preparing rare earth perovskite/biochar composite materials, can solve the problems of waste of resources and utilization rate of less than 10%, and achieve reduction of preparation costs, increase of effective contact, and improvement of catalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]Take the pomegranate skin and dry and graze it to get the pomegranate powder. 1.30 g of nitrate and 1.60 g of iron nitrate were dissolved in 100 ml of deionized water, and 3.0 g of pomegranate powder was added, stirred at 60 ° C, stirred for 6 h, and the pH was added to neutral, and the resulting suspension was filtered. The dry research was ground to get the powder, and the air furnace is 150 ° C (temperature rise rate 2 ° C / min) to heat the temperature for 2 h, and the finished product is obtained (Lafeo3 / C).

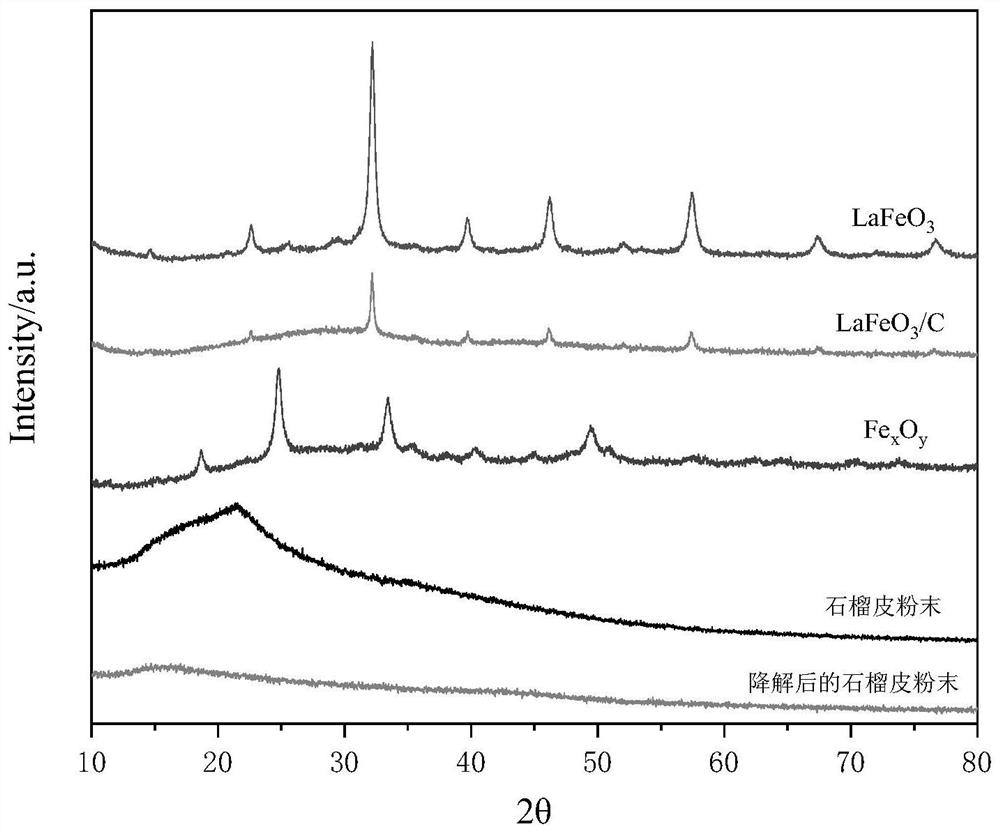

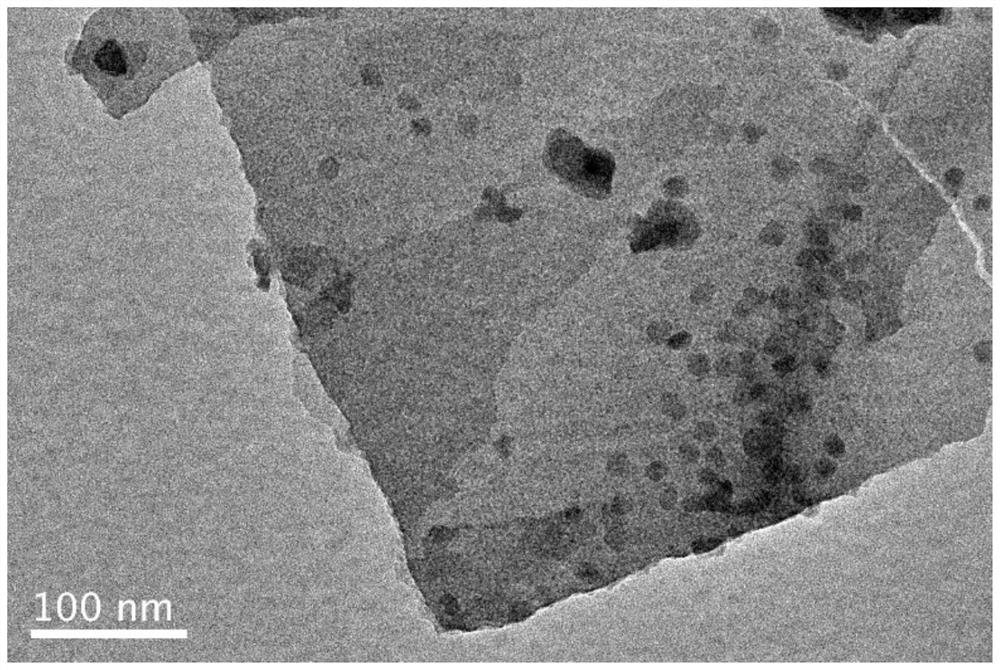

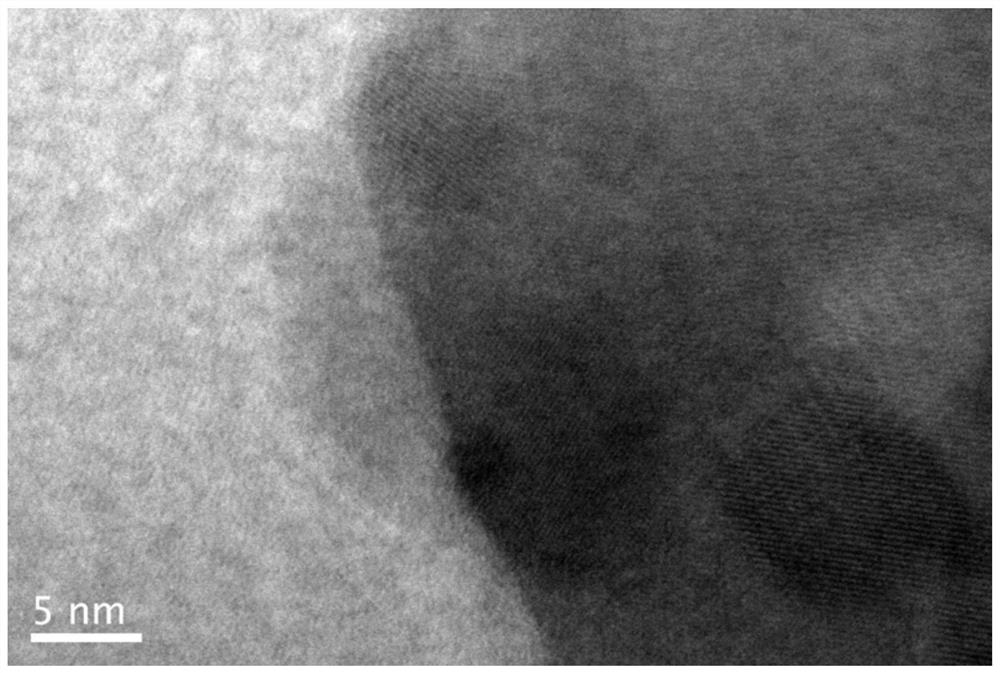

[0033]X-ray powder diffraction experiment was performed on the obtained sample, and its morphology and structure were observed under transmissive electron microscopy, and the iron-carbon / biocarbon nanostructure composite made of process parameters of Example 1 was obtained, and XRD spectrum with ferrite Such asfigure 1 Disted by control Lafeo3The PDF card can be known, at the angle = 22.6 °, 32.2 °, 39.7 °, 46.2 °, 57.4 °, 67.4 °, etc., Lafeo appears.3A unique diffr...

Embodiment 2

[0039]Take a straw to wash and dry and graze it, get straw powder. It is weighed 1.30 g of nitrate and 1.60 g of nitrate dissolved in 100 ml of deionized water, add 4.5 g of straw powder, stirring at 80 ° C, heat at 8 h, and the pH is added to neutral, and the resulting suspension is filtered. Grinding powder, the air under the air furnace 250 ° C (temperature rise rate 2 ° C / min) is held for 2 h, and the finished product is obtained (0.75LAFEO)3 / C).

[0040]Subsequent tests as in Example 1,120min NH4+The concentration reached 0.051 g / L.

Embodiment 3

[0042]Wash the lotus petal to dry and graze it to get the lotus petal powder. It is weighed 1.30 g of nitrate and 1.60 g of iron nitrate dissolved in 100 ml of deionized water, add 6.0 g of a water lobe powder, stirred at 90 ° C, stir in 9 h, and add ammonia to regulate pH to neutral, the resulting suspension is filtered Dry research grinding the powder, the air under the air furnace 350 ° C (heating rate 2 ° C / min) is held 2 h, and the finished product is obtained (0.5LAFEO)3 / C).

[0043]Subsequent tests as in Example 1,120min NH4+The concentration reached 0.047 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com