Method for preparing tungsten carbide platinum-loading catalyst in solution combustion synthesis mode

A platinum catalyst and solution combustion technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems that have not been seen in literature and application reports, and achieve low cost, high efficiency, and improved catalytic performance. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

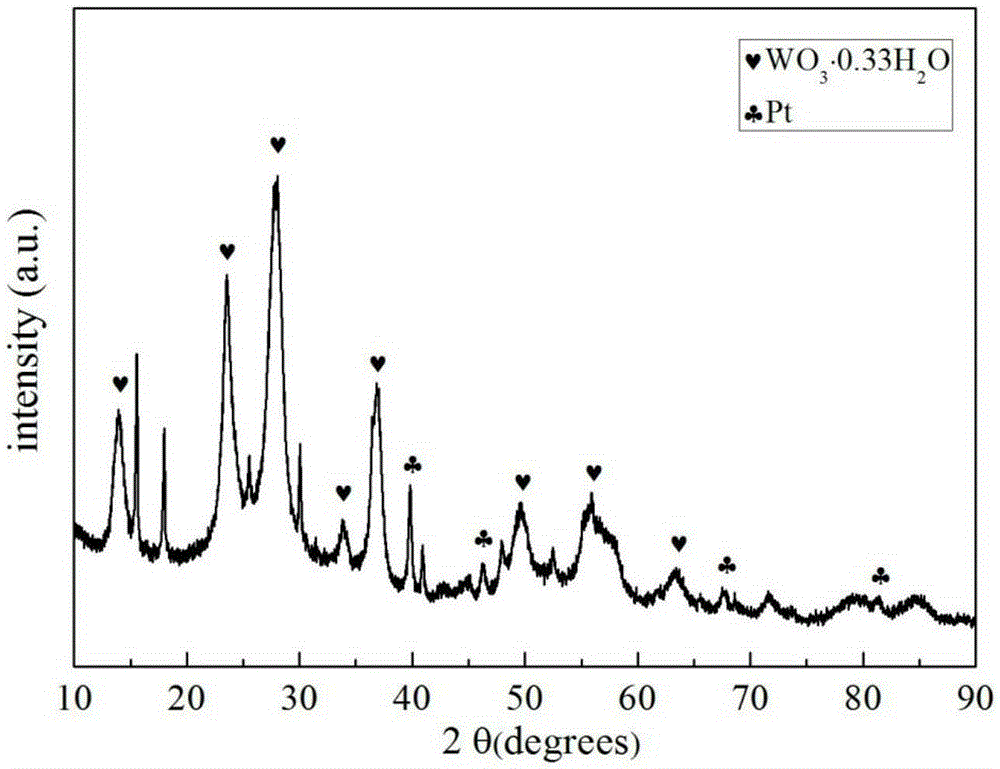

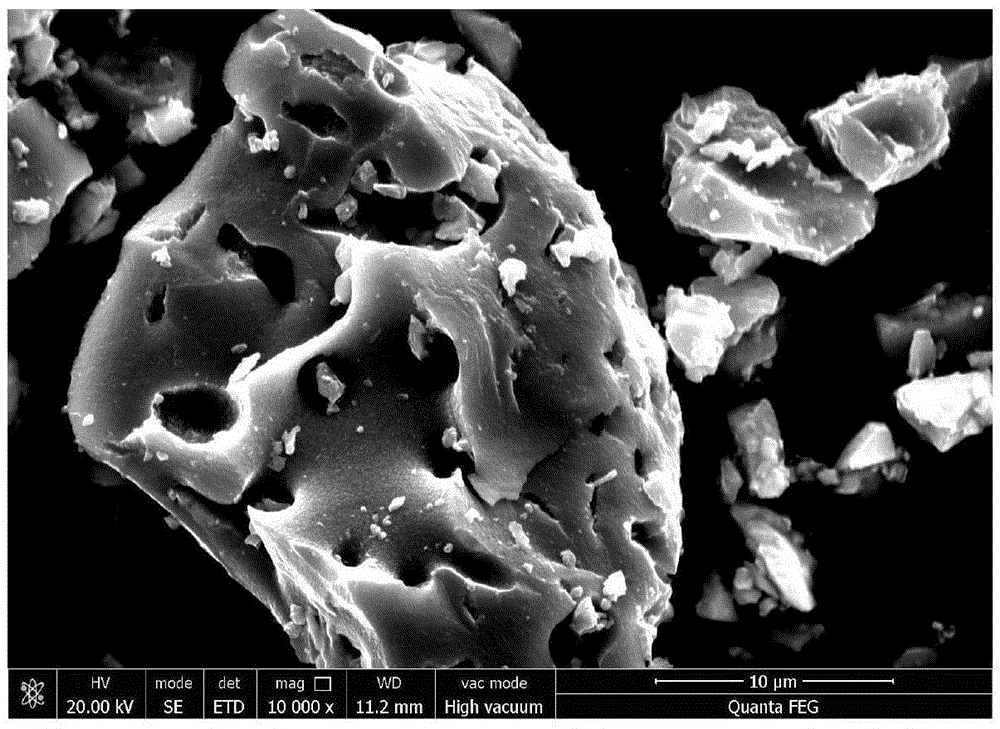

Embodiment 1

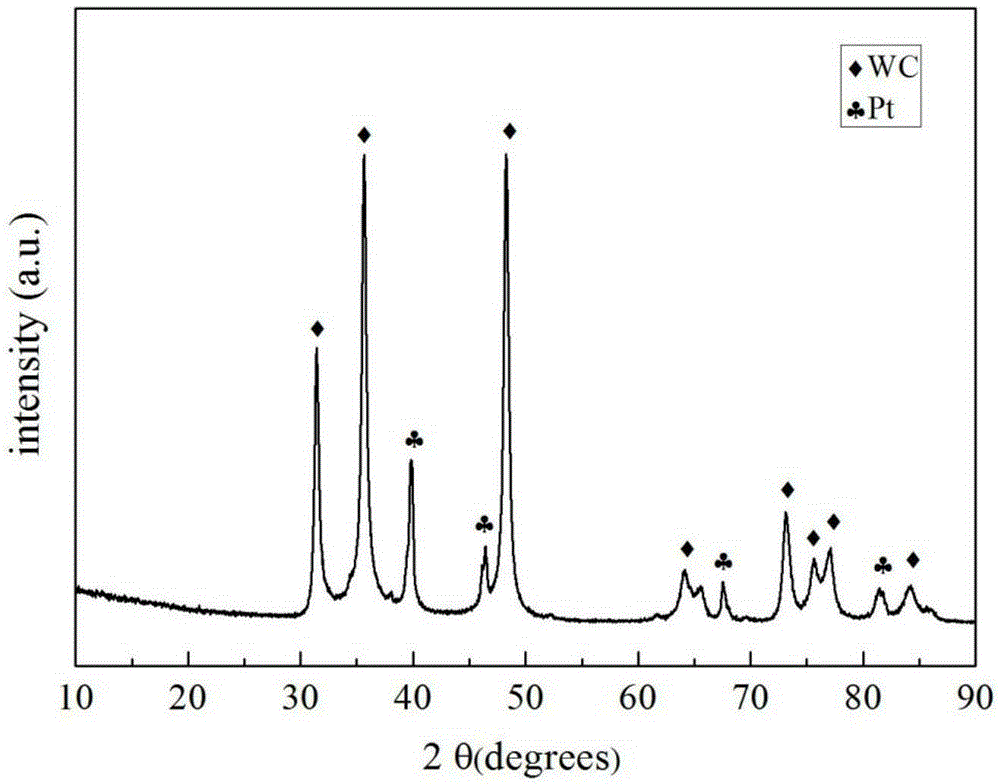

[0024] Weigh 0.0075mol of ammonium tungstate, 0.05mol of urea, 0.1mol of nitric acid, 0.09mol of chloroplatinic acid, and 0.07mol of glucose, add 100ml of deionized water, and mix well in a 500ml beaker. Place the mixed solution on a closed electric furnace to heat, turn on the electric furnace to the maximum power, and stir while heating. The solution reacts after a series of processes such as volatilization, concentration, and bubbling to obtain the precursor powder. Take the precursor powder out and grind it into powder in a mortar. The obtained powder was put into a square graphite boat, and carbonized in a tube furnace protected by argon at a carbonization temperature of 900°C and a heating rate of 3°C / min. After holding for 4 hours, it was slowly cooled with the furnace to obtain tungsten carbide-supported platinum catalyst powder.

Embodiment 2

[0026] Weigh 0.0075mol of ammonium tungstate, 0.05mol of urea, 0.1mol of nitric acid, 0.09mol of chloroplatinic acid, and 0.07mol of glucose, add 100ml of deionized water, and mix well in a 500ml beaker. Place the mixed solution on a closed electric furnace to heat, turn on the electric furnace to the maximum power, and stir while heating. The solution reacts after a series of processes such as volatilization, concentration, and bubbling to obtain the precursor powder. Take the precursor powder out and grind it into powder in a mortar. The obtained powder was put into a square graphite boat, and carbonized in a tube furnace protected by argon, with a carbonization temperature of 1000°C and a heating rate of 3°C / min. After holding for 6 hours, it was slowly cooled with the furnace to obtain platinum catalyst powder supported on tungsten carbide.

Embodiment 3

[0028] Weigh 0.0075mol of ammonium tungstate, 0.05mol of urea, 0.1mol of nitric acid, 0.09mol of chloroplatinic acid, and 0.07mol of glucose, add 100ml of deionized water, and mix well in a 500ml beaker. Place the mixed solution on a closed electric furnace to heat, turn on the electric furnace to the maximum power, and stir while heating. The solution reacts after a series of processes such as volatilization, concentration, and bubbling to obtain the precursor powder. Take the precursor powder out and grind it into powder in a mortar. The obtained powder was put into a square graphite boat, and carbonized in a tube furnace protected by argon, with a carbonization temperature of 1100°C and a heating rate of 3°C / min. After holding for 6 hours, it was slowly cooled with the furnace to obtain tungsten carbide-supported platinum catalyst powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com