Catalyst for lowering combustion temperature of soot in diesel exhaust gas and preparation method thereof

A technology of soot particles and combustion temperature, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of less research on eliminating soot particles, Achieve the effect of simple method, fast burning speed and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 0.025 moles of lanthanum nitrate, 0.015 moles of cerium nitrate, 0.01 moles of potassium nitrate, 0.04 moles of nickel nitrate, 0.0075 moles of cobalt nitrate, 0.0025 moles of palladium nitrate, add 50 milliliters of deionized water, stir to dissolve, and then add 0.075 mole of citric acid was dissolved by stirring to obtain a viscous liquid. Put this liquid in an oven at 70°C and slowly evaporate until a viscous gel is obtained, then transfer it to a clean enamel dish, spread it evenly, add about 50 ml of absolute ethanol, and ignite it in the air Finally, the gel undergoes self-propagating combustion, and finally produces an extremely bulky dark brown powder. The obtained powder was collected, transferred to a crucible, placed in a muffle furnace, and fired at 850° C. for 18 hours.

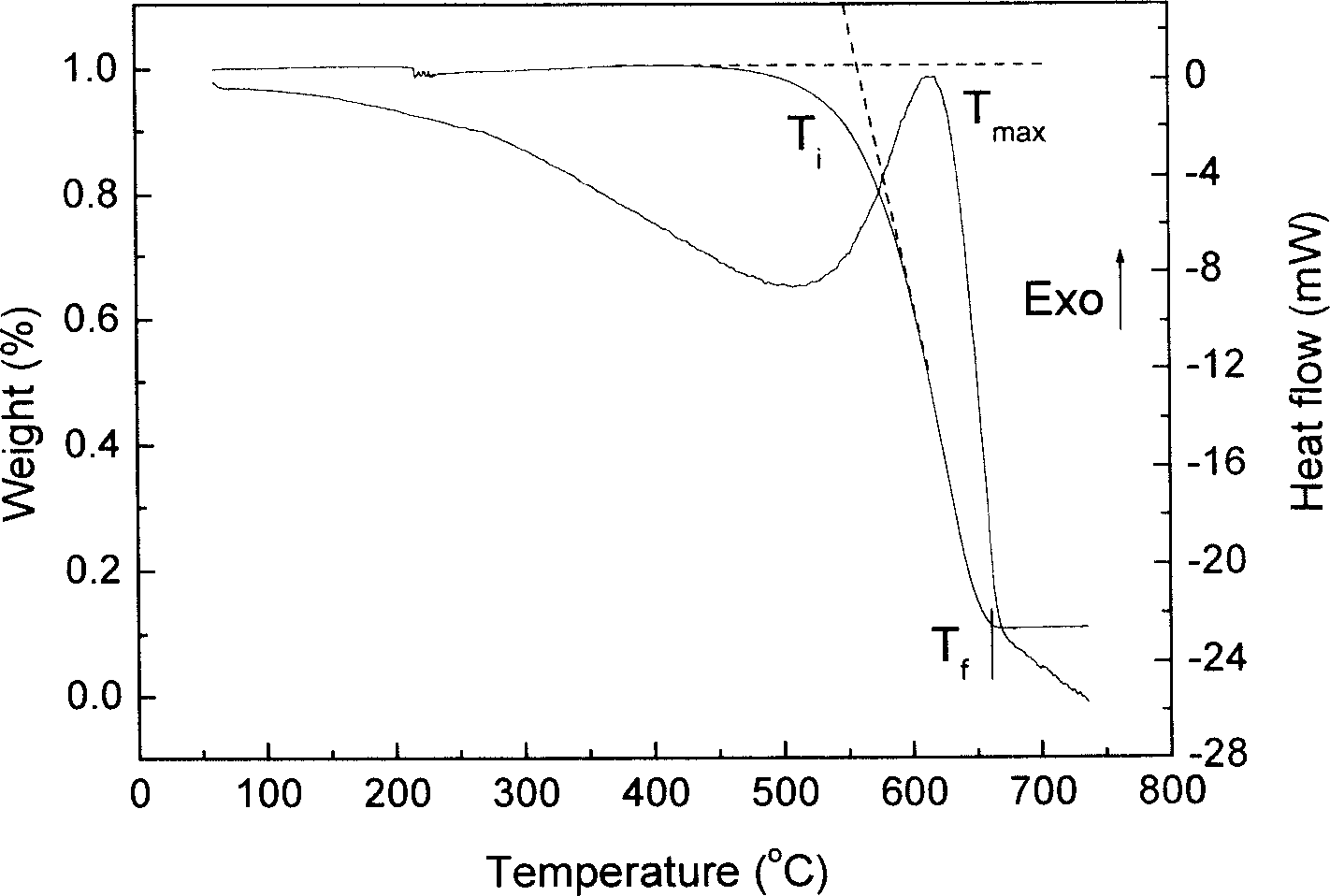

[0027] Mix the above-mentioned catalyst and soot particles in a mass ratio of 9:1, grind them in an agate mortar for one hour, put them into a platinum crucible of a thermal analyz...

Embodiment 2

[0029] Weigh 0.025 moles of lanthanum nitrate, 0.015 moles of cerium nitrate, 0.01 moles of potassium nitrate, 0.04 moles of nickel nitrate, 0.0075 moles of cobalt nitrate, 0.0025 moles of palladium nitrate, add 50 milliliters of deionized water, stir to dissolve, and then add 0.075 mole of citric acid was dissolved by stirring to obtain a viscous liquid. Put this liquid in an oven at 70°C and slowly evaporate until a viscous gel is obtained, then transfer it to a clean enamel dish, spread it evenly, add about 50 ml of absolute ethanol, and ignite it in the air Finally, the gel undergoes self-propagating combustion, and finally produces an extremely bulky dark brown powder. The obtained powder was collected, transferred to a crucible, placed in a muffle furnace, and fired at 850° C. for 18 hours.

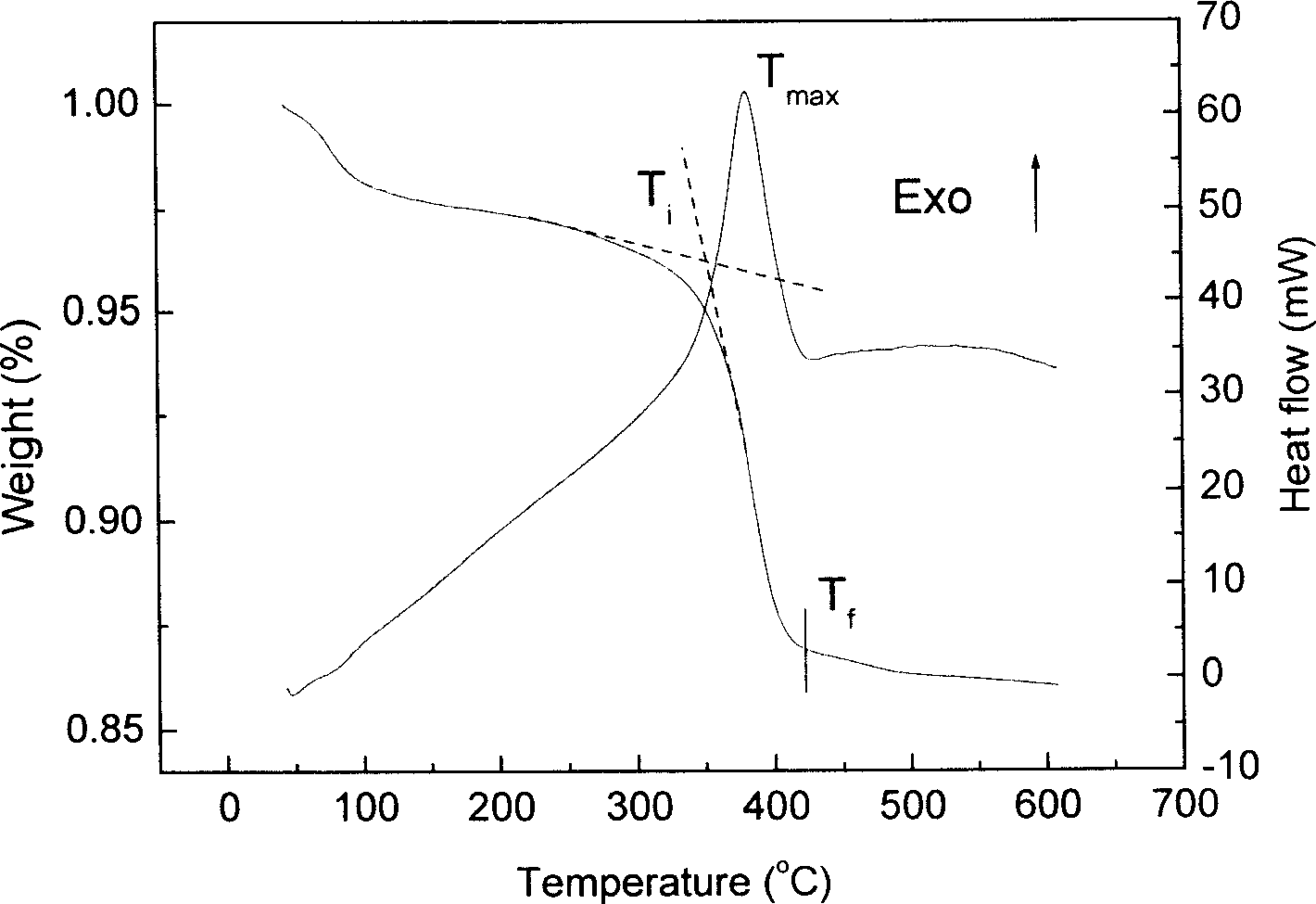

[0030] Mix the above-mentioned catalyst and soot particles in a mass ratio of 9:1, shake them evenly in a weighing bottle for one hour, put them in a fixed-bed reactor, and mix the...

Embodiment 3

[0032] Weigh 0.025 moles of lanthanum nitrate, 0.015 moles of cerium nitrate, 0.01 moles of potassium nitrate, 0.04 moles of nickel nitrate, 0.0075 moles of cobalt nitrate, 0.0025 moles of palladium nitrate, add 50 milliliters of deionized water, stir to dissolve, and then add 0.075 mole of citric acid was dissolved by stirring to obtain a viscous liquid. Put this liquid into a muffle furnace heated to 350°C, and the solution is burned to obtain a fluffy catalyst powder, which is then calcined at 850°C for 18 hours.

[0033] The combustion initiation temperature of the soot particles is measured according to Example 1, generally at 300°C-400°C. The combustion initiation temperature of the soot particles is measured according to Example 2, generally at 250°C-350°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com