Catalyst for accelerating burning rate used for reducing pressure exponent of nitramine propellant

A technology of propellant and burning rate, applied in physical/chemical process catalysts, nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, chemical instruments and methods, etc., can solve the unsatisfactory combustion performance of NEPE propellants and other problems, to achieve the effect of good compatibility, easy availability of raw materials and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

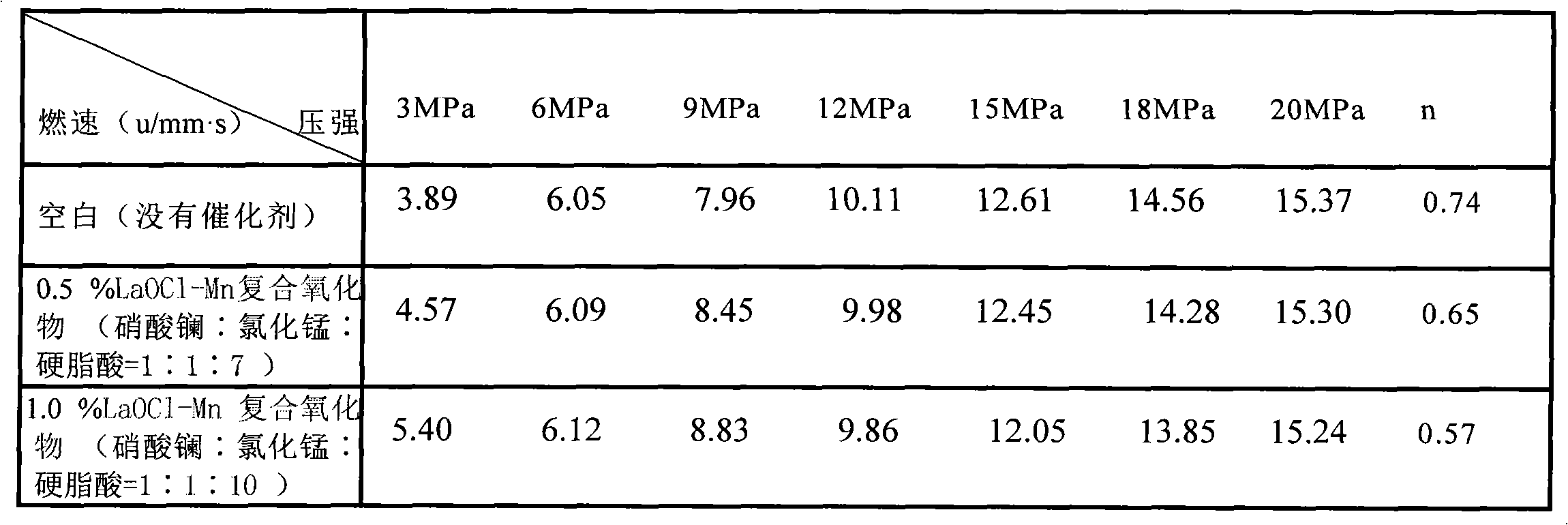

[0015] According to the molar ratio of lanthanum nitrate: manganese chloride: stearic acid=1:1:7, weigh lanthanum nitrate, manganese chloride, and stearic acid. Under the condition of heating in an oil bath, first melt the stearic acid, and under constant temperature magnetic stirring, melt the lanthanum nitrate and manganese chloride solids into the molten stearic acid, and control the temperature at 112°C to form a uniform stearic acid complex Put it in a muffle furnace at 500-600°C and burn it to get the LaOCl-Mn composite oxide.

[0016] Make high-energy NEPE nitramine propellant according to the following ratio. Adopt PET / NG / TG type NEPE propellant formula (Al: 15%~18%, AP: 15~20%), the composition and content are as follows: PET / N-100 is the binder system, the content is 7%~8% ; NG / TEGDN is a plasticizer with a content of 18% to 20%; solid filler reserves of 72% to 75%. Among them, the relative molecular mass of PET is Mn=4280, hydroxyl value: 26.4mgKOH / g, chain segmen...

Embodiment 2

[0021] According to the molar ratio of lanthanum nitrate: manganese chloride: stearic acid=1:1:10, weigh lanthanum nitrate, manganese chloride, and stearic acid. Under the condition of heating in an oil bath, first melt the stearic acid, and under constant temperature magnetic stirring, melt the solid lanthanum nitrate and manganese chloride into the molten stearic acid, and control the temperature at 117°C to form a uniform stearic acid complex The product solution is placed in a muffle furnace at 500-600°C and burned to obtain the LaOCl-Mn composite oxide product.

[0022] The propellant preparation and combustion performance test methods are the same as in Example 1, and 1.0% of the obtained LaOCl-Mn composite oxide product is added to the NEPE propellant.

[0023] The experimental results show that the prepared LaOCl-Mn composite oxide is compatible with the NEPE propellant system, the catalyst has little effect on the curing reaction of the slurry, and the normal propella...

Embodiment 3

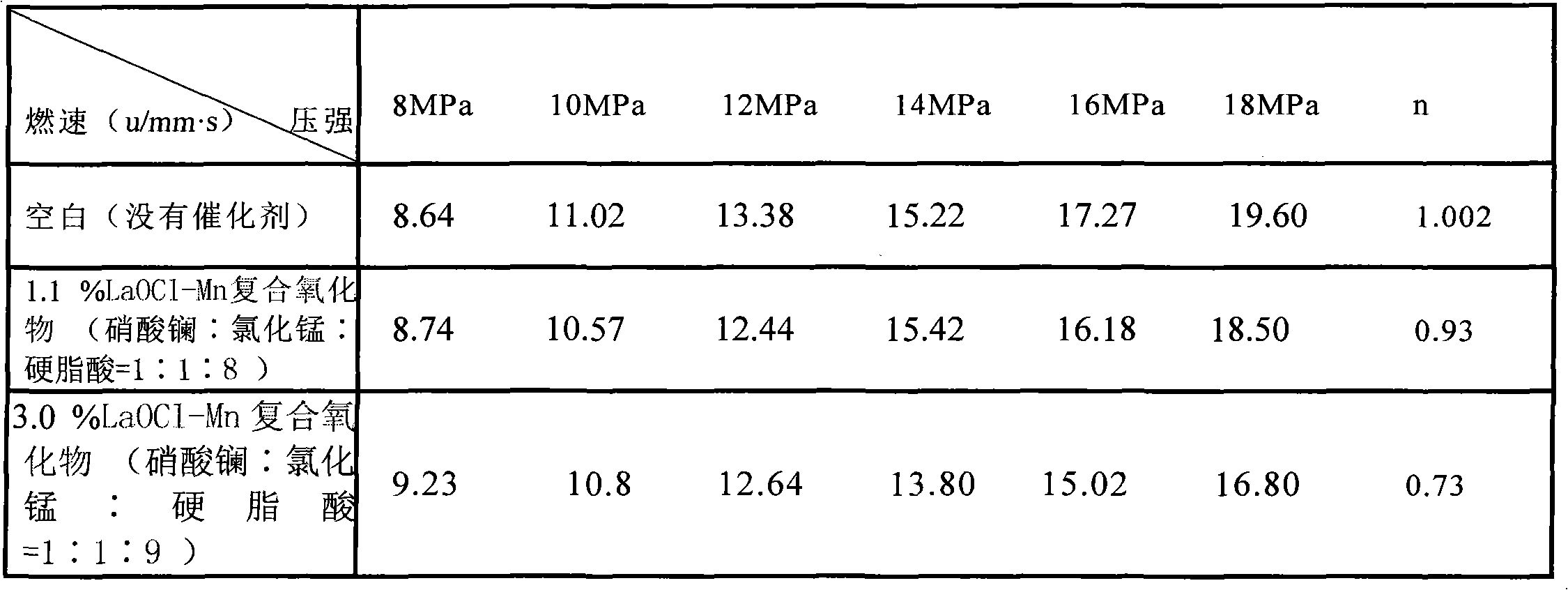

[0028] According to the molar ratio of lanthanum nitrate: manganese chloride: stearic acid=1:1:8, weigh lanthanum nitrate, manganese chloride, and stearic acid. Under the condition of heating in an oil bath, first melt the stearic acid, and under constant temperature magnetic stirring, melt the solid lanthanum nitrate and manganese chloride into the molten stearic acid, and control the temperature at 117°C to form a uniform stearic acid complex The product solution is placed in a muffle furnace at 500-600°C and burned to obtain the LaOCl-Mn composite oxide product.

[0029] Preparation of nitramine modified propellant: propellant formula without any catalyst: NC (nitrocellulose) plus NG (nitroglycerin) is 41.5%, RDX is 55.7%, functional additives and others are 2.8%, no catalyst; Catalyst formula: 41.3% of NG plus NC, 55.7% of RDX, 2.0% of functional additives and others, and 1.1% of catalyst. The experimental results obtained are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com