Heat stabilizer containing liquid barium and zinc, preparation method thereof and application thereof

A heat stabilizer and liquid barium-zinc technology, which is applied in the production method of liquid barium-zinc stabilizer and its application field, can solve the problems of reducing production costs and disadvantages, and achieve the effects of low production cost, rapid action and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

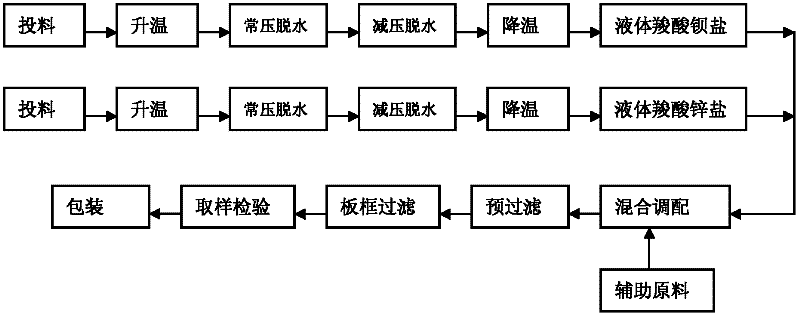

[0033] Example 1: Heat stabilizer containing liquid barium and zinc (see the process flow chart figure 1 )

[0034] 1. Preparation of liquid barium carboxylate: In a 2000L enamel reactor, put 567kg of oleic acid, 66kg of benzoic acid, 92kg of p-tert-butylbenzoic acid, and 193kg of odorless kerosene into the 2000L enamel reactor. Put barium hydroxide octahydrate (Ba(OH)) into the reactor 2 ·8H 2 O) 321kg, heat up to 100℃ after the cast, start the normal pressure distillation dehydration reaction, about 2h basically no water vapor out, and then under the conditions of temperature 110℃, vacuum degree ≥ 0.09Mpa, the dehydration reaction is continued under reduced pressure until nothing Moisture is removed, dehydration is stopped and the temperature of the system is reduced to 85°C to obtain a clear and light yellow oily transparent liquid for use;

[0035] 2. Preparation of liquid zinc carboxylate:

[0036] In a 2000L enamel reactor, put 234kg of isooctanoic acid, 78kg of benzoic acid, ...

Embodiment 2

[0040] Example 2: Heat stabilizer containing liquid barium and zinc (see the process flow chart figure 1 )

[0041] 1. Preparation of liquid barium carboxylate: In a 2000L enamel reactor, put 465 kg of oleic acid, 84 kg of benzoic acid, 86 kg of p-tert-butyl benzoic acid, and 193 kg of odorless kerosene into the 2000L enamel reactor. Start stirring and turn on the steam to heat up to 70°C. Put 425kg of barium hydroxide octahydrate into the reaction kettle. After the addition, the temperature is raised to 100°C to start the atmospheric distillation dehydration reaction. The reaction is about 2h, and the stirring is stopped when there is almost no water vapor. Then the temperature is 110°C, the vacuum degree is ≥0.09Mpa Under the conditions, the dehydration reaction is continued by vacuum distillation until anhydrous gas is removed, the dehydration is stopped, and the temperature of the system is cooled to 85°C to obtain a clear and light yellow oily transparent liquid for use;

[00...

Embodiment 3

[0046] Example 3: Heat stabilizer containing liquid barium and zinc (see the process flow chart figure 1 )

[0047] 1. Preparation of liquid barium carboxylate: In a 2000L enamel reactor, put 423 kg of oleic acid, 105 kg of benzoic acid, 123 kg of p-tert-butyl benzoic acid, and 193 kg of odorless kerosene into the 2000L enamel reactor. Start stirring and turn on the steam to heat up to 70°C. Put 512kg of barium hydroxide octahydrate in the reaction kettle. After the addition, the temperature is raised to 105°C and the normal pressure distillation dehydration reaction is started for 2h until almost anhydrous gas is removed. Then, under the conditions of temperature 110°C and vacuum degree ≥0.09Mpa, vacuum distillation Continue the dehydration reaction until anhydrous gas escapes, stop the dehydration and cool the system to 85°C for later use, to obtain a clear and light yellow oily transparent liquid.

[0048] 2. Preparation of liquid zinc carboxylate: In a 2000L enamel reactor, put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com